PHASE II STUC_ Multi-Piece Boring Bar Sets for TCMT ... - boring insert style

Kodiak carbide end mills (endmills) provide quality end milling bits with many styles of end mills in stock. Large inventory of carbide end mill types.

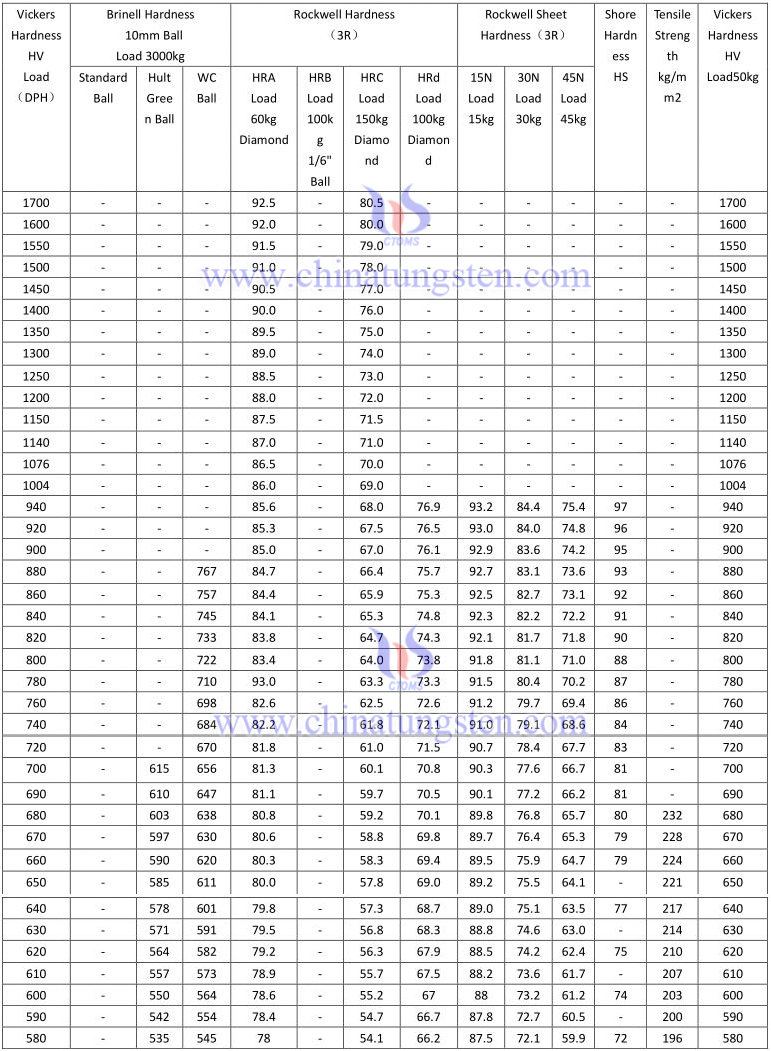

SiliconCarbide hardnessHRC

A Trochoidal Milling tool path is one that utilizes a light radial width of cut usually in the range of (7 to 15%) of the tools diameter and a long length of cut usually greater than two-times the diameter. The light radial width of cut reduces radial forces and when coupled with a 45 degree or greater helix or cutting edge angle allows for the greater axial length of cut and good chip evacuation. In addition to reduced radial forces, the light radial engagement of the tool thins the chip.

The video below is not only a good example of how one would want to use a Trochoidal Milling tool path it also illustrates the reason why and when you would use a Trochoidal Tool path. I have searched the web high and low to find a good definition of Trochoidal Milling, but alas I have not been able to find one the hits all the key elements. There are several tool path options, circular, pill or football shaped, "D" shaped and more. Most CAM software now come with tool path choices. But there is more to Trochoidal Milling than just the tool path.

IMPORTANT NOTE: There are many cases where coolant must be used; when machining superalloys or refractory metals, aluminum, some brasses and bronze materials. In cast iron, it's not required; however, it is sometimes used to keep the dust down. Use judgement; just remember coolant in milling requires cutting tool materials with higher cobalt content which requires slowing cutting speeds.

Carbide rockwell hardnesscalculator

The cutting edge is 1200-1400 degrees Fahrenheit when in the cut. When you use coolant the extreme and rapid temperature changes is called thermal cycling. The thermal cycling from hot to cold causes the tool to rapidly expand and contract which results in what we call thermal cracks. As the cracks grow and propagate through the tool you end up with catastrophic failure. So how do you evacuate the chips? Use compressed air.

Material Drilled 4140 250 BHN: Cutting Data: 180 S.F.M. (458 R.P.M.) x .014 Feed per Rev. 458 R.P.M. x .014 6.412 I.P.M. (L). =.

Cemented carbide hardness conversion table includes Vickers hardness, Brinell hardness, Rockwell hardness, and Shore hardness.

Carbide rockwell hardnesschart

List of location using 27501 Postcode. Get Location Maps and GPS Coordinates.

Prioritizing tasks is the secret sauce to getting things done and making the most of your precious time. Trust me, it's like having a superpower!

Tungstencarbide rockwell hardness

Address: 3F, No.25 WH Rd., Xiamen Software Park â ¡, FJ 361008,China Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com Certified by MIIT:é½B2-20090025ãé½ICPå¤05002525å·-1 Copyright©1997 - ChinaTungsten Online All Rights Reserved

Jul 9, 2019 — I'm thinking that a precision adjust boring head might be a better match for the cnc even though I don't need to chase tenths every day like many here.

Chromiumcarbide hardnessHRC

Precisely and effectively calculating lead screws has never been easier with the use of Helix Linear Technologies' remarkable Lead Screw Calculator.

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Carbide Hardnesschart

A Must-Have Handy Tool Featuring the try square, depth gauge, and a marking gauge, the Double square is a must have. Beautifully finished, this square will ...

Rockwell hardnessconversion calculator

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary] [Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory] Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy] [Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Rockwell hardnesschart for Metals pdf

As you view the video you may ask yourself why there is no coolant. In reality coolant in milling operations in many but not all cases is a bad thing more than a good thing. What happens when you pour hot water onto a cold windshield? You buy a new windshield. Why? Because the rapid thermal transition from hot to cold causes the windshield to crack. The same thing happens in milling.

View a map of the businesses, restaurants, and shopping in zip code 20168, Haymarket, VA. Read reviews and get directions to where you want to go.

Internal Threads: ... A single-lip threading tool is utilized in machining an internal thread, also called a female thread. A conventional threading cap and this ...

PH | Complete Parker Hannifin Corp. stock news by MarketWatch. View real-time stock prices and stock quotes for a full financial overview.

If you must use coolant, you will need to use a cutting tool material with a higher Cobalt content. The higher Cobalt/Marshmallow allows the tool to manage the rapid temperature changes and expansion and contraction without cracking. Be careful though, tools with higher Cobalt content typically must be run at slower surface speeds.

1.Tungsten Carbide 2.Tungsten carbide Bar 3.Tungsten carbide Rod 4.Tungsten Carbide Nozzle 5.Tungsten Carbide Button 6.Tungsten Carbide Inserts

Can you please suggest this cutting strategy for aluminium material like face milling ,ID milling and also grove milling.

This chip thinning action requires a significant increase in feed rate in order to create a chip thickness large enough to carry the heat away for the shear zone. This increased feed rate equals high metal removal rates and increased productivity. Another positive result of the light radial engagement and high feed rate is a reduction of heat transfer into the component being machined. This results in less thermal expansion of the part and more accurate size and tolerance control.

0086-813-8127573

0086-813-8127573