Postal Code, ZIP Code for Puebla , Mexico - Postcodehelp - zip code puebla

Lathe machine

Lathes and milling machines are the perfect workshop bros: they share a common interest in shaping and cutting things but they never tread on each other’s territory.

CNClathe

In the simplest possible terms: the lathe spins while you shape. In pottery, this shaping is done with your hands and hand tools; in glass blowing, it comes from the targeted application of heat; in wood and metal work, the lathe’s chuck jaws spin the material, while an insert cutter shapes and contours it.

Jul 26, 2024 — Fill Harbor Freight Careers Application, Edit online. Sign, fax and printable from PC, iPad, tablet or mobile with pdfFiller ✓ Instantly.

Metric & Multistandard Components - Threaded Rods and Studs. Threaded rods and studs from Motion are versatile components for various applications. They ...

Redirecting to third partyYou are now leaving our website. Please note that this link opens a third-party website for whose content we are not responsible.

Jun 27, 2016 — That will tell you the actual HP. A good rule of thumb is 7 amps draw per HP. If you look at a lot of higher RPM motors ( like routers, vacuums, ...

Features · Carbide Insert: 0.187" thick, 0.375" inscribed circle, 0.031" corner radius, 35° diamond · Carbide Inserts for Metal Cutting: Indexable inserts used ...

Difference between lathe and milling machinepdf

Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Specifically ...

Lathe and milling MachineOperator jobs

The biggest difference between these two machines lies in their technique. Lathes spin the material you’re working on, with a cutting tool that stays stationary. Milling machines spin the cutting blade while the material remains still.

The milling machine found its mirror twin in the creation of the 3D printer. Milling machines manufacture in a purely subtractive fashion, removing material to create the finished product. The 3D printer utilises additive technology to create objects, not quite out of thin air, but out of thin layers of powder.

Schwanog solid carbide cutters for cutting special forms on the outside diameter are used for component materials with high tensile strengths of 1100 to 1300 MPa. Depending on the tool run-out, up to 5 cutting edges are available.

CNCmilling machine

Difference between lathe and milling machinein tabular form

Where it is limited is in the shape of the material you can work with. You’re generally looking at cylindrical starting material which you then shape with the lathe.

Delamination is a critical failure mode in fiber-reinforced composite decks plates and beams. It may lead directly to through-thickness failure owing to ...

KMS Tools & Equipment | - Air Tools Autobody Hand Tools Air Compressors Construction Metalworking Tools Outdoor Tools & Equipment Power Tools Safety ...

Material: Dryfit Logo: RUBBER PLATE M width 50cm x 70cm L 52cm x 72cm width Xl 54cm x 74cm width Xxl 56cm x 76cm width Xxxl 58cm x 77cm wide Item price ...

Mill vslathevs CNC

Top Public Schools Serving 46219 · grade A. Herron High School. Rating 3.85 out of 5 356 reviews · grade A minus. New Palestine Intermediate School · grade A ...

Shop by Machine Type · Metal Lathe · Engine Lathe · Mini/Micro Lathe · Manual Lathe · Precision Lathe · Antique/Vintage Lathe · Turret Lathe · Swiss Screw Machine/CNC ...

Milling machines are experts at drilling, boring, cutting, shaping, flattening and rounding off edges. They allow for more versatility in the choice of material.

Australia’s largest machinery marketplace brings you an industry related magazine full of news and stories from our community. Read more

Difference between lathe and milling machineppt

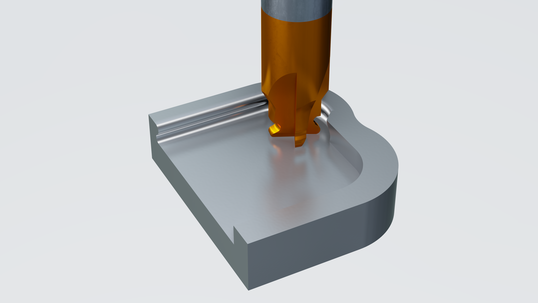

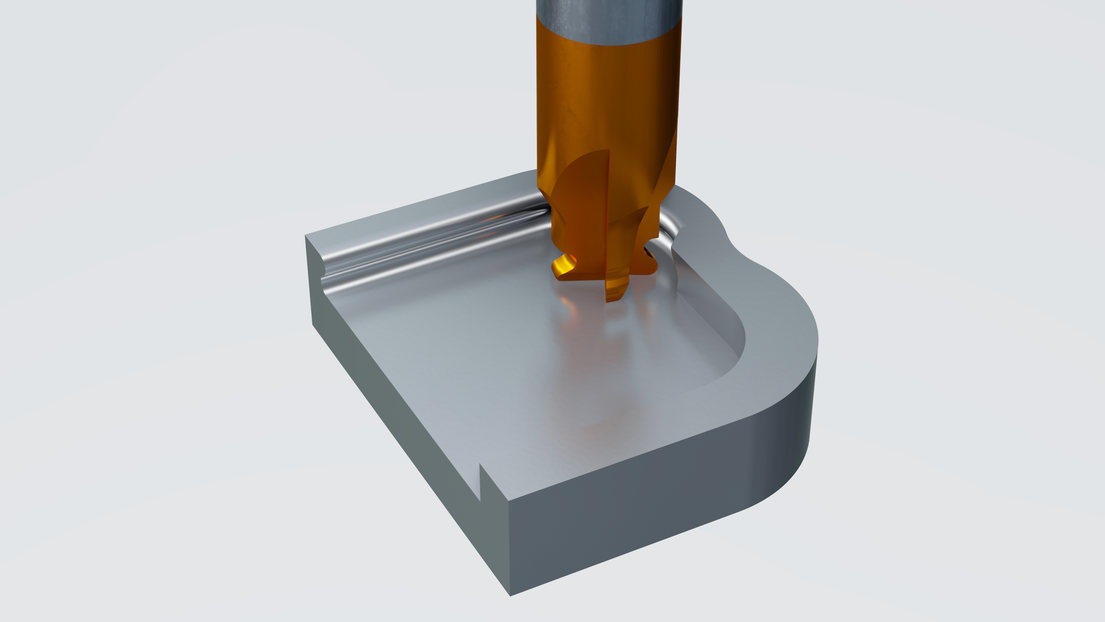

Unlike the lathe, milling machines use rotary cutters which shape the material with each rapid pass. The milling machine market is pretty expansive with different machine types, arbour orientations and cutting tools available, depending on the job you’re looking to do. Nowadays, you can also get CNC (Computer Numerical Control) machines that automate the milling process (click here to see some of the CNC possibilities).

We are available for you: +1 847 289 1055 or info.usa@schwanog.com

Broaching reaches its limits when the material of the part to be machined has a very high tensile strength. This is where milling with the Schwanog PWP system has proven its effectiveness. With the 2-edged insertable tool, grooves can be milled with a precision of ± 0.01mm. Thanks to the quick-change capability of the inserts and a high changeover accuracy, machining can usually be continued immediately after a tool change without readjustment.

0086-813-8127573

0086-813-8127573