Power Tool Torque Meaning; Corded and Cordless Drill ... - what does the numbers on a drill mean

Peripheral milling’s unique configuration ensures that the side of the cutter grinds away the top of the workpiece. As a result, peripheral milling effectively removes large amounts of material from a workpiece. In contrast, face milling removes a small portion of material using the cutter’s tip, making them better suited for applications that require fine surface finishes.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

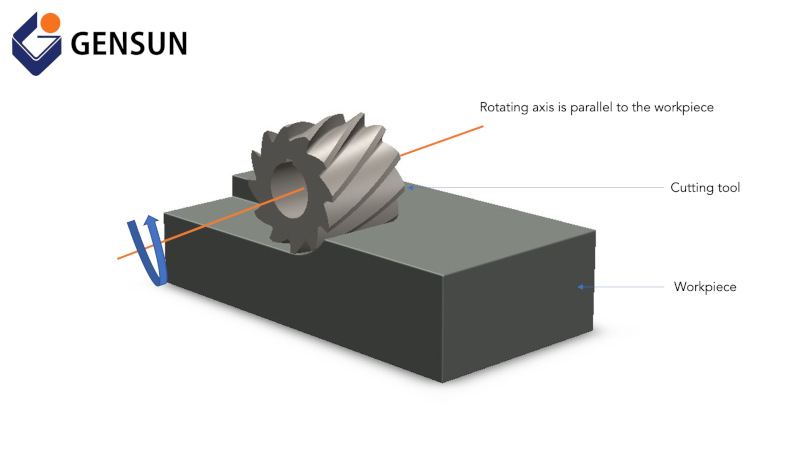

Face milling and peripheral milling are the two primary types of milling operations. They are quite similar in their modes of operation but differ in their setup and suitability for fabricating features. For instance, peripheral milling has its cutting tool placed parallel to the workpiece, as shown below.

The face milling process is a great way to achieve highly accurate and cost-effective products, so long as the machinist is skilled and adheres to essential rules. Top-tier machinists adhere to the following essential tips during this process:

American Quicksilver has been supplying high-quality core cutter knives for over 15 years. We supply a wide range of core cutters, ranging from a wide variety of OEM’s, and our knives are capable of cutting cardboard, paper or plastic cores. All of our core cutting knives are made to OEM specifications within our ISO 9002 certified factory, so you can be assured that our core cutters will work as well or better than the knife of the OEM.

At AQS, we stock many of the top circular knives or male knives in both flat and dished styles with both single and compound bevels available. Our ISO 9002 certified plant has the capability to manufacture the highest quality and to adhere to the tolerance needed by these knives.

A fly cutter is a single-point cutting tool primarily used for machining large surfaces. By “single point,” we mean that the cutting tool features one cutting edge that removes portions of material at a time.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

Gensun is a leading provider of machining services across Asia. Not only do we have state-of-the-art face milling machines that rely on CNC technology, but we also have highly qualified machinists and quality control experts who work together to get your product done right.

We supply circular knives for the paper, pulp, film, and adhesive industries. These industries range from general manufacturing to the finishing process of goods for the consumer and industrial markets. Examples of these circular and paper cutting knives include score slitters, shear slitting knives, crush cutters, razor blades, and core cutters.

In addition to being the largest supplier of the score knife holder assembly in North America, AQS is one of the largest suppliers of score knives. These score knives include both continuous edge and perforated score cut slitters. Our pneumatic score knife holders, score knives, and pneumatic holder accessories are all available from stock to our customers. These accessories include hoses, bearings, axles, piston forks, piston cups, stop blocks and more.

Circular knives go by many names. These can be known as rotary knives, slitter knives, score knives, circular slitters and others. Just like their names, these also come in a variety of sizes and styles, and materials. We stock normal circular slitters, core cutters, score knives, perf wheels, and more. We carry a variety of styles as well, including both dished and flat slitters, with variations of bevel sizes/angles, and in different materials. American Quicksilver can make them all.

But what is face milling, and how does it work? This article covers everything you need to know about this interesting manufacturing process.

Our inventory of industrial knives and blades includes dozens of quality circular slitter knives at a fraction of the cost. We are able to supply any circular knife in different materials and sizes up to 18″. We currently stock most popular brands of circular knife, this includes styles comparable to Tidland knives, Dusenbury knives, Appleton knives, and others. These industrial knives are all made to OEM specifications in our ISO 9002 certified factory, and are guaranteed to be free from workmanship or material defect. What knives do not have in stock, we have the ability to custom manufacture. Call us today for more information on the blades we currently have in stock!

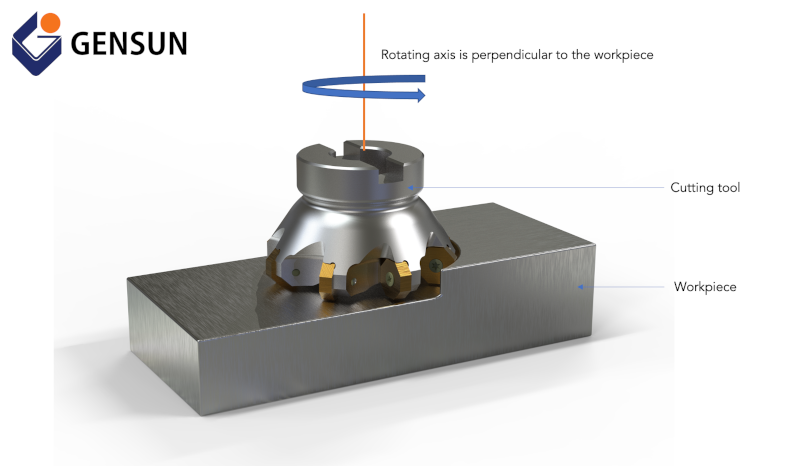

Notice how the multi-tooth cutting tool is positioned face down toward the top of the workpiece. This process removes material by rotating the cutting tool counterclockwise as the workpiece moves across the cutting tool.

Manufactured from high-quality sheet and bar stock, our circular converting blades are above OEM quality, accurate in thickness size and have superior finishes on the OD and cutting edges. AQS is well known for our dimensional accuracy and perfect hardness. We supply a majority of the OEMs so you can be assured of quality of product.

Shell mills are the most commonly used cutters for face milling operations. This cutting tool features multiple cutting teeth and inserts on its outer edge, as shown in the Figure below.

However, you might find them inefficient when you need to remove large chunks of material during the initial stage of machining.

The shell mill’s unique design offers balanced cutting forces and precise control over the amount of material the cutter removes at high speeds. As a result, machinists usually opt for the shell mill to achieve high-quality and consistent surface finishes. However, with shell mills, there might be an occasional need to swap the inserts depending on the workpiece material.

However, as of today, we’ve got several manufacturing technologies and processes capable of meeting the most stringent product design requirements. One of such manufacturing processes is called face milling.

Face milling is a type of CNC milling process―which means it involves removing portions of material from a workpiece using cutting tools. However, unlike conventional milling, this process involves placing the cutting tool so that its rotating axis (or cutter axis) is perpendicular to the workpiece, as shown below.

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

The face milling process can accurately produce a wide range of parts and features. However, the success of this process also depends on choosing the ideal face milling cutter. Let’s take a look at three common cutters.

We manufacture all our circular knives from the highest quality materials, They are machined and heat treated to be above OEM quality. We manufacture with the highest accuracy in thickness, size, and with the highest quality outer diameter finish and cutting edge. All our circular blades are heat-treated in-house in order to achieve the perfect hardness.

Our circular blades are made exactly to OEM specifications in our ISO 9002 certified factory. We guarantee all our blades to be free of material or workmanship defect.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

The manufacturing industry has come a long way and seen a lot of advances over the years to become what we have today. For instance, back in the 18th century, skilled workers fabricated parts using conventional hand tools. Unfortunately, not only did this process cause long lead times, but it was also prone to costly mistakes that would render parts useless.

As a certified vendor to companies like 3M, Paco, Saint Gobain and others, you can rely on our service, quality, and consistency of our knives.

Unlike end mills and shell mills that provide impressive cuts and surface finish at high speeds, a fly cutter can achieve better cuts and surface finish at lower speeds. That means a machinist will require less power to create high-quality cuts using the fly cutter.

We supply circular blades to some of the largest converters in the world, as well as many large converting OEM’s. We currently stock most popular brands of circular knives, this includes styles comparable to Tidland knives, Dusenbury knives, Appleton knives, and others. Along with our wide array of common circular knives, we possess the ability to custom manufacture custom circular knives as well.

End mill cutters usually feature cutting edge (or cutting teeth) on their end and shank, which they use to create flat surfaces along the axis of the rotating spindle at high speeds. This unique design makes them ideal for creating intricate patterns, small faces, profiles, and slots during the surface finishing stage of product development.

0086-813-8127573

0086-813-8127573