Precision boring mill solutions - boring bar mill

Multi-Axis Capabilities – Some CNC machines are capable of multi-axis movement, allowing complex threading on components with unconventional shapes and orientations.

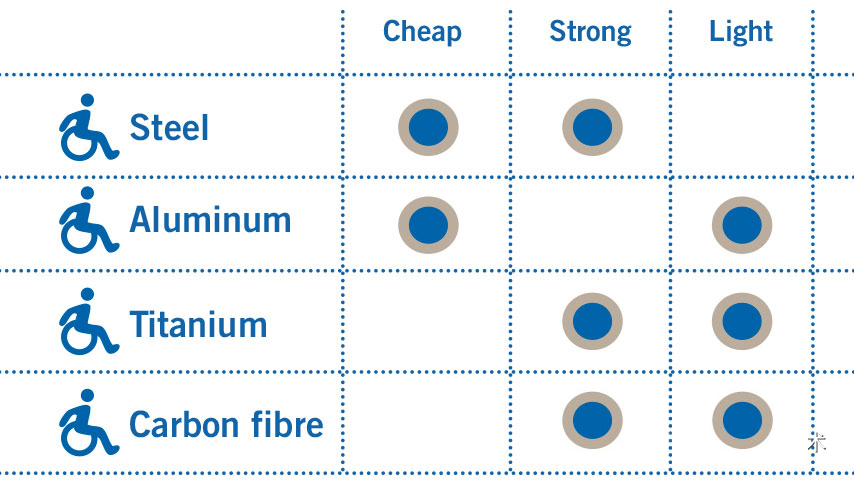

Steel is generally a more cost-effective material than carbon fiber. In contrast, there are many factors affecting the cost of carbon fiber, mainly including the cost of the manufacturing process, the cost of skilled labor and the cost of materials. So, producing carbon fiber is a very time-consuming process, but it's worth it in the end. While carbon fiber components may cost slightly more, they are stronger, lighter, and much more durable than steel components.

Handle All Types of Materials – CNC machines can handle almost all types of materials and that includes metals like steel, aluminium, plastics, and composites. This ability makes it suitable for all kinds of industries.

CNC machines are very much essential for the oil and gas industry as they can produce robust, high-precision threads that can ensure leakproof connections in oil piping and other important equipment.

Carbon fiber modulus of elasticityvs steel

The aerospace industry is one such industry where the demand for quality is extremely high. The industry needs high-quality components that can withstand extreme pressures, temperatures, and vibrations.

The CNC threading process is mostly applied in industries where precision, strength, and reliability are very important. Here are a few industries where CNC threading is most commonly applied.

Carbon fiber modulus of elasticityformula

Complex Threading Operations – CNC threading can perform intricate thread profiles and non-standard thread geometries that would be challenging or impossible to achieve manually

Flexibility – Another major advantage of CNC threading is its ability to create various types of threads. It can also handle both the internal and external threads, offering versatility for different applications.

High Precision – One of the main advantages of CNC threading is that the CNC threading machines are capable of producing threads with amazing accuracy and consistency. They ensure consistent thread dimensions and tight tolerances, which are crucial for quality and reliability in mechanical connections.

carbonfibre tensile strength (mpa)

Benefiting from the characteristics of high specific strength and high specific modulus, carbon fibers have been widely used in many applications. Sometimes people compare carbon fiber to metallic steel. When comparing carbon fiber and metallic steel, it is not difficult to see that both carbon fiber and steel have properties that provide unmatched performance in specific applications. But if you want to understand which material is better, you need to know the key difference between carbon fiber and steel. This article will take you briefly to understand the characteristics and main differences between carbon fiber and steel.

Carbon fiberdensity

Consistency – The CNC threading process ensures uniformity across multiple parts, which is very crucial. This consistency helps in reducing the errors in the manufacturing process, making it the best for high-volume production.

CNC threading is a highly efficient and specialized process that is used in industries that need high-quality components with precision engineering. CNC threading plays a very important role in the production of high precision, durable, and reliable components that are safe and durable for the above said industries.

Speed and Efficiency – Automated CNC threading machines can operate at higher speeds compared to manual threading, significantly reducing production time while maintaining quality, especially in repetitive tasks.

Carbon fiber modulus of elasticitygraph

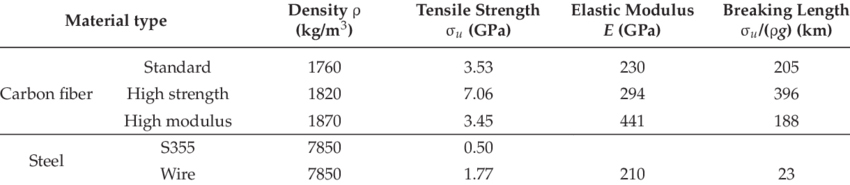

Although both carbon fiber and steel have strong deformation resistance, the density of steel is much higher than that of carbon fiber. Generally speaking, the weight of carbon fiber is only about one-fifth of that of steel, so that is to say, under the same weight, carbon fiber The strength is about five times that of steel.

Cured epoxy can react to sunlight and other elements, but carbon fiber itself is made of a chemically stable material and is resistant to corrosion, making it perfect for applications in harsh environments.

Cost-Effective for Large Batches – While CNC machines may have higher initial setup costs, they become highly cost-effective for large-scale production due to their efficiency and low error rates.

Carbon fiberPoisson ratio

When it comes to the automotive industry, CNC threading is used in engine components and transmission systems. The engine and transmission system needs quality components for breakdown free running of the automobiles.

Carbon fibertensile strength

Reduces Tool Wear & Improves Tool Life – CNC machines use precise cutting technology, and this reduces the wear and tear of the tools and improves the tool life.

While steel is often considered the standard material in construction and industrial settings, carbon fiber is actually much stronger than steel in terms of strength-to-weight ratio. When applied, strength is defined by a material's resistance to deformation, or modulus of elasticity. Both carbon fiber and steel have elastic moduli above 200 gigapascals (GPa), so both materials are very stiff and ideal for many applications in high stress areas.

Steel, on the other hand, is extremely susceptible to oxidation when exposed to atmospheric moisture (although some alloy steels have better corrosion resistance), so carbon fiber is undoubtedly superior in terms of corrosion resistance.

Carbon fiberyield strength

One of the major advantages of CNC threading is that the CNC threading machine is programmed to cut threads with very high precision with the help of various tools like thread mills, and taps. The CNC machine follows a programmed approach and this helps in getting consistency and accuracy across multiple parts.

To sum up, both steel and carbon fiber are very strong, and depending on what they are used for, their construction is durable. Both have their own strengths and positions in industrial settings, and it's safe to say that carbon fiber won't replace steel anytime soon.

Both steel and carbon fiber are common in industrial and everyday applications, and both are primarily known for their superior strength and durability. In everyday applications, both steel and carbon fiber are reliable materials that can withstand long-term wear. But of course, there are some notable differences between the two. Mainly reflected in the following aspects:

CNC threading plays a major role in the construction and heavy machinery industry. The heavy equipment used in the construction industry needs to be strong. These threads ensure that the components in the heavy equipment hold together, under stress and in a harsh environment.

CNC threading is the process of creating threads using CNC threading machines. Threads are used for fastening or as mechanical connections, and they are important for the components in equipment to hold together. They are mostly used in industries like aerospace, automotive, and construction.

Due to its unmatched strength-to-weight ratio (specific strength), carbon fiber is the first choice for some applications where weight must be kept to a minimum (e.g. aerospace, sporting goods, etc.).

0086-813-8127573

0086-813-8127573