Premium (Made in US) Industrial Grade Cobalt Drill Bit, 3/8 - cobalt drill bit 3 8

Are Black and Deckerdrill bitsuniversal

Need additional assistance selecting the right drill bit for your workpiece material or application? Contact our tech team!

DoBoschdrill bits fitBlack and Decker

Mar 11, 2023 — I just want to take a moment to share my experience during my visit this past week at Harrelson trumpets. ... trumpet mouthpieces, and I'd have to ...

DoDewaltdrill bits fitBlack and Decker

A driving and drilling set like this 60 piece Drilling and Driving Kit is a necessity because it has some items that the other two sets don’t have, such as:

Let’s talk about drill and drive bits and some other important accessories you’ll need in your DIY toolbox (and how to easily choose the correct one!).

Buy online at discount prices Helical Solutions high performance solid carbide endmills for aluminum, Helical carbide endmills for steels, Helical carbide ...

Try to avoid the cheapest drill bits, or you could likely end up spending more in the long run. Always use cutting oil or coolant for any drilling operation.

The three kits I’ll be featuring in this post can be found at Home Depot. These RYOBI drill and driver bit sets are pretty useful. Each have similar components but they all have something different amongst them, as well. They include:

equations, tables and figures of microanalysis, microfabrication, microelectronics, semiconductor in English.

Jan 23, 2024 — Student aid and education planning ... Enter your claim on the Tradesperson's tools expenses line (1770) of Form T777, Statement of Employment ...

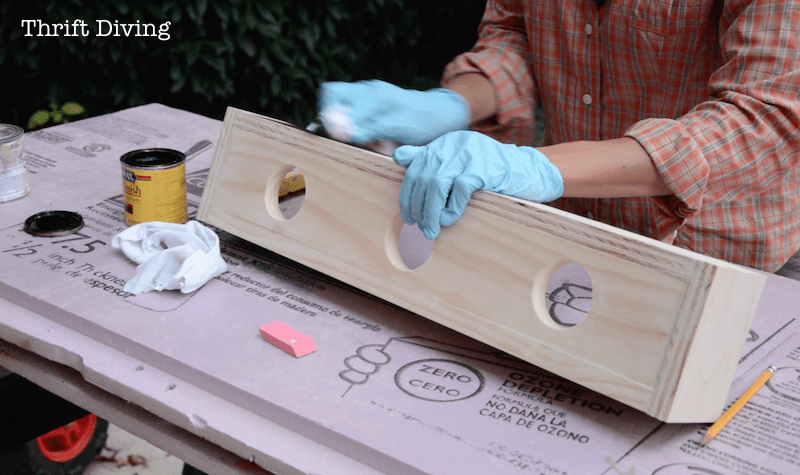

Thrift Diving inspires women to decorate, improve, and maintain their home themselves...using paint, power tools, and thrift stores! Use these 5 printables, checklists, and ebooks to get started!

This kit also has a set of black oxide drill bits that are pretty standard when drilling wood where precision and cleanliness isn’t that important.

Since there are different types of driving bits for different types of screws: Phillips, slotted (also called flathead), square (also known as Roberston, hex, and torx), choose the right type of driving bit for the fastener you’re using.

I use dish soap and warm water with a nail brush to scrub my bits, and then I soak them in lucas cide rtu for 60 seconds to disinfect, rinse, ...

This 60 piece Drilling and Driving Kit has a couple different types of drilling bits, including brad point drill bits (my favorite) for drilling wood and plastic with precision and for clean holes. That sharp tip will keep your drill bit in place so that it doesn’t “walk” when you start drilling.

If you’re a DIYer like me who is always doing projects that involve drilling and driving, then these RYOBI drilling and driving kits are pretty important to have in your DIY toolbox.

DoDewaltdrill bits fitRyobi

There are several sizes of Phillips driving bits, though (e.g. a small PH0….PH1, PH2, PH3, to a larger PH4, which these sizes are indicated on the side of the driving bit. “PH” stands for “Phillips.”). So you’ll need to choose the one that is seated completely into the head of the screw. One that is too small or too large will strip the screw, as I previously mentioned.

Depending on the screw gauge, that will determine the size of the driving bit you’ll use. If you’re not sure of the size of the screw, you can use a screw thread checker like this one from Amazon.

If you’d like, you can use wood filler over this screw to hide it if you’re painting over it. But overall, it just looks neater/cleaner than having the screw sitting upon the wood surface.

A really nice overview of the difference between drivers and drills, and the various bits. Even though I’ve been doing this a while and learned a bunch of good stuff! Thanks, Serena!

I’m Serena Appiah (rhymes with IKEA). I think home should be affordable. All you need is paint, power tools, and thrift stores.read more >

Whether you’re using a power drill or a hammer drill, though, you need to use drill bits suited for masonry. You’ll notice that the heads are blunted, but with a hammer head to them.

by MS Seehra · 2018 · Cited by 22 — The noble and precious metals correspond to a selection of the transition-metal group of the periodic table (see Figure 1), including copper (Cu), silver (Ag), ...

Topics: Aluminum, Video, Metalworking and Machining, Holemaking, Drilling, Rushmore USA, TTC, Viking, Precision Twist Drill, Carbon Steel, Stainless Steel

Check out our latest video, and learn how to select the right drill bit to use for the job. Take the guesswork out of drilling holes in metal, as Kurt Repsher walks you through our recommendations for drilling hardened or stainless steels, mild or carbon steels, and aluminum. Subscribe to our channel to see more exclusive how to videos and tips from the pros.

An impact driver is fantastic at driving fasteners much faster and with more power. As a result, you better believe you’ll need driving bits that are labeled “impact rated.” Bits that are impact rated means you can use them in a regular power drill or an impact driver.

Do all drill bits fitfor metal

When drilling hardened or stainless steel, select a drill point of at least 135° or higher. This spreads the workload out over a larger cutting surface. Since hardened steel and stainless steel are both quite difficult to drill into, using a drill press or a milling machine should provide the best results.

If you’d like to get your hands on some of these drilling and driving kits, and to learn more about them, you can find all of these sets at The Home Depot.

So let’s review some important questions to ask to make sure you’re choosing the right size and shape when selecting a driving bit.

We believe the Right Tool Is Everything™, and we strive to share our experience and expertise in an effort to ensure you select the right tool for your application, follow best practices, and can push your productivity further.

A hole saw is a great accessory for drilling holes, as well, because sometimes you want a hole that’s bigger and uniform without having to pull out a jigsaw.

Stainless steel can actually ‘work harden’ as it heats up—so keep your cool, take your time, and make sure the tool and work area stay well lubricated.

I didn’t know this, but this colorful coating seen around these impact rated bits (the band of yellow) indicate that this tip is impact rated. The design of the head and the coating helps to increase wear life.

Getting good results when driving screws is usually based on 1) choosing the right size and shape driving bit, 2) drilling a pilot hole when needed before driving a screw, and 3) using the right tool for the job.

It’s possible to drill into wood, plastic, metal, masonry, and more. But the material you’re driving in to will determine which driving bit you’ll use. And there are different types of drilling bits, as well.

Cobalt drill bits are best suited for use on hard to machine metals, including hardened or stainless steel. Cobalt is blended in with High Speed Steel to make the drill bits harder and more wear resistant. As each cobalt drill bit consists of High Speed Steel with a small percentage of cobalt, the higher the percentage of cobalt, the more heat-resistant and durable the drill bit is.

Whatdrill bits fitBlack and Decker

I’ll be the first to admit that I’ve stripped my fair share of Phillips head screws because the driving bit was too skinny or too fat. It’s frustrating getting to the point where the poor driver bit just keeps spinning and you know that you better STOP and switch to a hand-held screw driver if you want to salvage what’s left of the screw! (….Or is that just me that does that??).

When you become a homeowner, one of the first tools you buy for your homeowners toolbox is a power drill. It’s one of the simplest power tools to use. I guarantee that you’ll grab it for hanging curtain rods, adding or changing knobs on kitchen cabinets, putting furniture together, and you might even try your hand at building furniture for your new pad.

DoBoschdrill bits fitDewalt

A good quality High Speed Steel (HSS) drill bit is suitable for use on mild steels, but if you need to get a lot of use from them, go with M35 cobalt drills, or even the aforementioned M42 cobalt drills.

Federal Broach & Machine Company LLC is a manufacturer of tools and machinery. Federal Broach & Machine Company LLC was founded in 1952. Federal Broach ...

One of my favorite bits is the countersink bit. Whenever you want your fasteners to lie flush or slightly below the surface, this bit create a nice cone-shaped divot in the wood.

A hole saw comes in the 60-piece set and is especially useful for cutting holes in doors or door locks and knobs, light figures, and even for crafty and creative projects, like this project I made using ceiling fan lights as candle holders. The hole saw was helpful in cutting 3 uniform holes evenly. Hole saws will allow you to cut holes easily anywhere from 1/2″ to 1-1/2″.

SEC Filings ; Nov 12, 2024, SC 13G/A. An amendment to the SC 13G filing ; Nov 08, 2024, 10-Q · Quarterly report which provides a continuing ...

Do all drill bits fitreddit

Adjust the cutting speed and/or feed based on your cutting conditions. ... Drill Diameter. SFM. (ft/min). Drill Diameter. METRIC. 1.0. 2.0. METRIC. 3.0. -. 4.0. -.

Aluminum is very easy to machine, but it’s abrasive, so cutting tools will tend to wear quickly. The best drill bits for aluminum are solid carbide because solid carbide is very hard and stays sharp much longer than other materials, providing extended tool life. If you’re only poking a few holes, high speed steel (HSS) is fine. Using a cobalt drill bit isn’t worth the extra cost because on aluminum, its performance level is about the same as that of high speed steel. Skip the coatings on these drills —there’s no need to increase the already high cost. Especially avoid any coating with “Al” in the ingredients (AlTiN, TiAlN, etc.). A drill bit with a bright finish is ideal.

Our key cutting service is fast, efficient and affordable. We carry a range of keys that cover the needs of most homes, business or motor vehicles.

It’s helpful to use a hammer drill when drilling into concrete or masonry. While it can be done using a regular drill (as I was able to drill into concrete when I fixed my shutters), it is definitely a job more suited for a hammer drill.

But while a power drill (or impact driver) is easy to use, what’s not easy is knowing what all the different drill and driver bits are used for in those handy little kits. And it’s hard to know which one you’ll need to use.

A driving bit is used to fasten screws, nuts, or bolts in order to keep secure materials together. Some of the common drive bits you’ll find in a set include Phillips, Slotted (also knowns as flathead), Square (also known as Roberston), Hex, and Torx (hex not pictured in this set below).

If you’ve ever chose the wrong driving bit to fasten a screw, you know how frustrating it is to strip the screw because you chose the wrong bit that’s too small or large. Stripping a screw is when the driver bit doesn’t fit on the screw head properly and the force of the rotating drill bit wears away at the head of the screw.

As a result, you’re left with a screw that (if you’re lucky), you will be able to flip your drill into reverse and back slowly (or use a hand screwdriver to carefully remove it). Or you might even have to use a buy a spiral screw extractor set for those stripped screws.

Each of them have similarities, such as the driving bits, but when you need drilling bits, and driving bits rated for impact drivers, it’s helpful to collect one or more of these to meet all of your building and creative needs.

Driver bits that are impact rated can withstand the high torque of an impact driver. Otherwise, you risk snapping your fasteners off clean in your project or risk breaking the bits. That’s what we don’t want!

A drill bit is a bit is used to drill holes, ranging from small to large. Some drill bits are made specifically for wood, plastic, metal, concrete, and more (we’ll talk about this in a moment). There are different types of drilling bits, which I’ll cover later. Keep readin’. ?

Each screw has a gauge (which is the diameter of the screw body). They typically range from sizes 2 to 16. The #8 sized screw is most common. Just remember when sizing screws: the larger the number, the more thicker the screw and the smaller the number, the thinner the screw.

0086-813-8127573

0086-813-8127573