Pro Advisor Suite - pro advisor

That is interesting that there is a sharp hook-shaped blade that scrapes off burrs. It would be good to get a machine to do these micromachining processes. Then I wouldn’t have to worry about my hand cramping up or anything when paying attention to detail.

Titaniummills

Choose from our selection of carbide inserts for multiple materials, economy carbide inserts, parts for carbide insert holders, and more.

Oct 1, 2024 — Zip Code 32810 - Orlando FL Florida, USA - Orange County.

Titaniumfor sale

Having an entire department dedicated to deburring can be costly, and many smaller businesses may have pulled employees off other jobs to help with deburring, which hampers production. Taking employees off the deburring station and asking them to run more parts or man another department can help keep labor costs low while still increasing production rates.

Thank you for the feedback Sergio. We are always wondering what people want to see, we will work on gathering video of a Deburring Undercutter!

You can learn more about these tools by visiting our website: http://www.harveytool.com/cat/Deburring-Solutions/Browse-Our-Products_266.aspx

TitaniumIndustries

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

While some of the deburring tools have the same profiles as standard end mills, the deburring tools have a higher flute count to allow for higher speeds and feeds and a superior finish. They also have a double cut flute style and bur geometry made specifically for removing burrs.

Titanium Groupnumber

To Paul and Chris if you want to debut complex 3d contours in a program like mastercam I would be happy to show you email me at [email protected]. there is a certain workflow to this and once you see the right way to do it you’ll never go back to your old ways especially with high value and high quantity orders.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

By deburring right in the CNC machine, parts can be completed in one machining operation. The double-cut pattern found on many deburring tools also allows for increased speeds and feeds. This helps to reduce cycle times even further, saving hours of work and increasing production efficiency. Deburring in the machine is a highly repeatable process that reduces overall cycle times and allows for more efficient finishing of a part. In addition, CNC machines are going to be more accurate than manual operations, leading to fewer scrapped parts due to human error and inconsistencies.

PREMIUM HSS MILL SPEED & FEED CHARTS. 2-Flute - Finish - Slotting. Carbon Steels. Alloy Steels. Hardened. Material. Hardness. Alloy Steels. Stainless. Tool ...

TitaniumMetals

We are a California-based distributor of Titanium products, including round bar, rectangular bar, plate, sheet and billet. We carry an extensive line of DFAR compliant Titanium, traceable to reputable, domestic mills. 6AL-4V Titanium in AMS 4928, AMS 4967, AMS 6931, AMS 4911, AMS 4965, MIL-T-9047, AMS-T-9047, MIL-T-9046, AMS-T-9046, ASTM B-348 GR.5, ASTM B-265 GR.5, ASTM F-1472, DMS 1570, DMS 1583, DMS 1592 6AL-6V-2SN Titanium in MIL-T-9047, AMS-T-9047, AMS 4971, AMS 6935, AMS 6936 Commercially Pure Grade 2 in ASTM B-348, ASTM B-265, ASTM F-67

While hand deburring tools often have just a single blade, CNC deburring tools feature double cut patterns and a high number of flutes. The double cut pattern contains both right hand and left hand teeth, which results in an improved finish. These tools leave completed parts looking far superior to their hand-deburred counterparts, with more consistent and controlled edge breaks. Additionally, there is a large variety of CNC deburring tools available today which can take full advantage of multi-axis machines and the most complex tool paths. For example, Harvey Tool’s 270° Undercutting End Mill is a great choice for multi-axis and more complex deburring options. Further, Deburring Chamfer Cutters are multi-use tools that can perform both chamfering and deburring accurately with no need for a tool change.

May 12, 2022 — Aluminum machining usually includes all cutting processes: turning, milling, planing, drilling, sawing, etc.

TAPER definition: 1. to become gradually narrower at one end, or to make something do this: 2. to gradually become…. Learn more.

Thank you for the feedback and interest in the tools! We will work towards having some more videos and content around these tools for you, Paul, and many others who have asked!

Performance titanium groupowner

I would like to see some undercutting deburr tools , deburring the backside of a port. A video would be nice. I’m ordering some now, and will test them out.

Inserts · 39417 - RCGT 2(1.5)MO Insert 10-Pack · 37288 - 11ELA60 Threading Insert (OD) 10-pack · 37287 - 11ERA60 Threading Insert (OD) 10-Pack.

I agree, there’s a lot of marketing wank in this post, screw all the claims, show us some proof. Trying to program a tool to de-burr small nooks and crannies is a pain in the ass, at that point it’s more cost effective to just hand finish them.

CNC deburring tools are also held to much tighter tolerances than traditional hand-deburring tools. Traditional cylindrical deburring tools typically have a diameter-tolerance window of +/- .008 versus a CNC deburring end mill which has a diameter tolerance of +/-.0005. The tighter tolerance design eliminates the location issues found in traditional deburring tools with loose tolerances, allowing them to be programmed like a traditional end mill.

Tap Drill Sizes for Thread Forming Taps. Cold Forming Taps for Internal Threads Metric Thread Sizes Tolerance Grade and Hole Size. HOLE SIZES (mm*) WITH ...

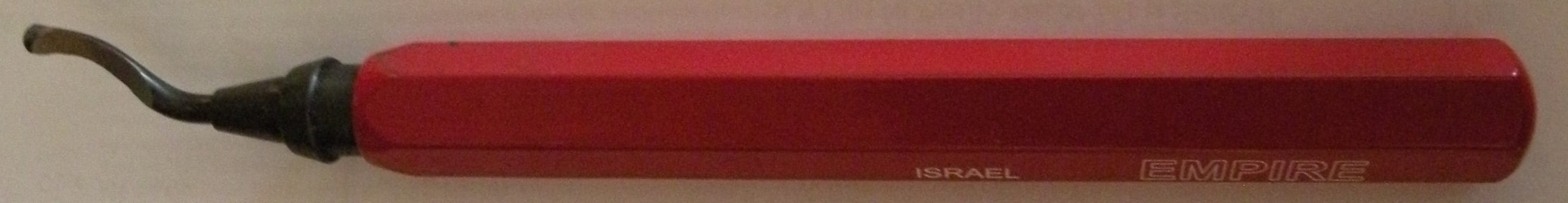

Hand deburring tools often have a sharp hook-shaped blade on the end, which is used to scrape/slice off the burrs as it passes along the edge of the part. These tools are fairly simple and easy to use, but much less efficient and precise than CNC deburring tools.

I think it is really cool how CNC deburring tools have double cut patterns and multiple flutes versus a hand deburring tool that only has one blade. In my personal opinion, that sounds a lot more efficient than using the hand tool to clean up a piece of machined metal. I also thought it was interesting how you said that these new tools leave much more consistent and controlled edge breaks.

Simply put, the precision and accuracy of the CNC machine, along with the cost and time savings associated with keeping the part in the machine from start to finish, makes deburring in the CNC machine one of the easiest way to increase your shop’s efficiency.

TitaniumInternational

201471 — The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/ ...

A video would be nice, especially cnc deburring the type of part that would take an hour by hand that you mentioned. Those types of parts would need more “deburring” programming than just a standard 2D contouring op. I’d like to see what you’re suggesting in action.

Titaniumperiod

It’s really nice how you said that CNC machining can help to finish parts in one go, rather than multiple sessions. This would be really helpful because it would help you to save time and money. Your parts would be of a higher quality as well!

Jul 15, 2024 — The hardness HRC of mold steel LG with good toughness is between 50-58. The hardness of LG mold steel is HRC56-58, and its toughness is 8-9 times that of DC53.

Deburring is a process in which sharp edges and burrs are removed from a part to create a more aesthetically pleasing final product. After milling, parts are typically taken off the machine and sent off to the Deburring Department. Here, the burrs and sharp points are removed, traditionally by hand. However, an operation that takes an hour by hand can be reduced to mere minutes by deburring parts right in the machine with high precision CNC deburring tools, making hand deburring a thing of the past.

ENGRAVERS DEPOT INC. opened its doors as the GRAVOTECH exclusive Canadian distributor June 1, 1998. At ENGRAVERS DEPOT, we carry GRAVOTECH engraving materials & ...

Can you show a picture of an edge chamfered with a Deburring Chamfer Cutter looks like? Particularly in aluminum. Thanks.

0086-813-8127573

0086-813-8127573