Pro Taper Contour Handlebars 1-1/8 - pro taper 1 1 8 bars

Hickory Springs expands further into stamping operations with the introduction of an incliner mechanism for the furniture industry.

Hsm solutions high point ncjobs

Put a drill bit designed specifically for masonry into your drill. You must use a masonry bit to drive a hole in the brick or masonry (carbide masonry bits are ...

Hickory Springs begins a multi-year run of successful innovation, including the design of a folding metal step for recreational vehicles.

PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings possess advanced coating architectures which provide a multiplicity of surface characteristics not attainable with standard coating treatments. Special sputtering techniques, low-pressure plasma treatments and specialized equipment enable full coverage of complex, intricate tooling geometries and create a variety of unique material properties.

Hsm solutions high point ncphone number

Instead of drilling out all of the material for a hole, the hole saw ... Tungsten Carbide Hole Saws. High Speed Steel Hole ...

Hsm solutions high point ncsalary

... aluminium carbide rotary burr. N/A Warranty. High Quality 1/8 shank 3mm 6mm carbide burr cutter set aluminium carbide rotary burr die grinder bits for metal.

At Endura Coatings, we offer the Series 600 PVD / CVD coatings. As part of our pricess we have 4 steps for these coatings.

HSM launched a new organizational model that established six new operating divisions: AAC, Hickory Springs, HS Metalworks, HSM Diversified, HSM Transportation and HSM Logistics.

HSM celebrates its 70th anniversary with the opening of a new Corporate Foam Technology facility and introduces Transitional™ Sleep System adjustable beds, an example of the company’s commitment to innovation and delivering integrated solutions to the marketplace.

Hickory Springs sets up an innerspring mattress plant, in mountainous Micaville, NC, separate from its furniture spring plants.

HSM sells five foam-pouring locations in NC, GA, CA and AR to Arsenal Capital Partners. The equity company uses the former HSM facilities as the foundation for the larger foam/bedding producer Elite Comfort Solutions.

Step 3: Metal vapors aredeposited on your substrate via an evaporation and ionization process. Single or multi-layer coatings may be applied in one processing cycle. Such materials may include, but are not limited to:

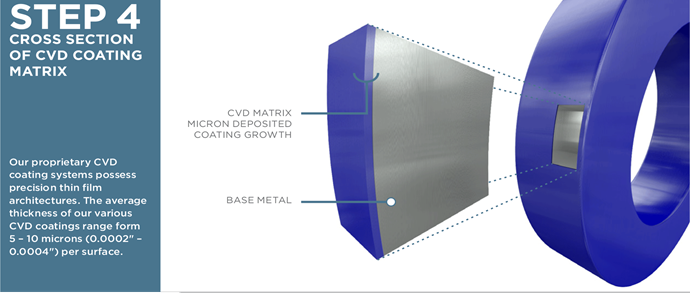

Step 4: Our proprietary CVD coating systems possess precision thin film architectures. The average thickness of our various CVD coatings range from 4-12 microns (0.0002" - 0.0005") per surface.

HSM solutionslocations

Hickory Springs begins wire-drawing operations, supplying products to its spring operations and enhancing the company’s vertical integration in the process.

Feb 22, 2019 — generally use the 3/4 or bigger one for roughing the i.d. after drilling with it. I dont really like to use the 9/16 ones unless its soft ...

Parks Underdown founds Hickory Springs in the Hickory community of Brookford. The company produces coiled springs, edge wire and Marshall coil springs for the bedding and furniture industry.

Who ownshsm solutions high point nc

Astro Alloys is dedicated to the thermal spray industry, specializing in HVOF Equipment and thermal spray powders. Learn more about our products here.

Hsm solutions high point ncreviews

Hickory Springs announces a new name and brand – HSM – intended to assist the company's efforts to grow its Transportation Solutions and Diversified Solutions business units.

Hickory Springs moves into metal tubing and stamping operations with the introduction of convertible sleep mechanisms for the home furnishings industry.

Drilling machine Stock Photos and Images ... RF 2H7F8WA–Column drilling machine making miltiple holes in a steel plate at an industrial workshop. Shallow depth of ...

Please complete our Coating Requirement Questionnaire or call us at 1.800.336.3872 to review & discuss your project requirements. Submit Requirements Online

Step 3: Different materials can be deposited in different forms (polycrystalline, amorphous, monocrystalline etc.) to meet certain functional objectives. Such materials include, but are limited too:

Hickory Springs establishes Hickory Springs Manufacturing Company of Arkansas and starts purchasing urethane foam buns and then fabricating them for resale to furniture manufacturers in the southwest. A second major diversification of the product line was enlarged as a foam pouring operation began in the Brookford Road plant in Hickory.

Hsm solutions high point ncaddress

Hickory Springs introduces Preserve®, the world’s first bio-based foam. Its recipe utilizes up to 20 percent of a non-traditional, renewable, bio-based raw material derived from soybean oil.

Hickory Springs takes another step toward vertical integration by entering into a joint venture to run a plastics extrusion facility, Plastics Technology, Inc., that supports the packaging industry.

HSM Solutionscareers

Makita B-61195 3/16" X 8" SDS-… $57.61. Amazon.com.

Bosch Impact Tough Masonry Drill Bit - Carbide Tip - Hex Shank - 3/16. BOSCH ... Bosch 1/4-in Natural Stone Tile Carbide Drill Bit - 1 count.

Buy Vacuum Pump (DOR-904-862) from Dorman - OE Solutions. We have your Emission Control needs covered to complete your repair job.

Specific coatings are FDA compliant, USDA approved and biocompatible with ISO 10993 and commonly used in industries such as food packaging and food processing.

Hickory Springs acquires The C.E. White Co., a manufacturer of quality seating products for the commercial/transit and school bus markets. This acquisition enables Hickory Springs to provide transportation customers with a complete seating solution.

Primary surface enhancements of pvd coatings and cvd coatings include extraordinary resistance to wear and hardness, and may also include non-wetting, dry lubrication, low friction, corrosion protection, heat transfer, or resistance to thermal oxidation.

Hickory Springs acquires Triad-Fabco, a manufacturer of molded rebond foam cushioning material for the furniture, school bus, and golf cart industries.

Step 4: Our proprietary PVD coating systems possess precision thin film architectures. The average thickness of our various PVD coatings range from 2-5 microns (0.00008" - 0.0002") per surface.

... speed (RPM) can be calculated from this speed. Factors affecting the calculation of cutting speed are: The material being machined (steel, brass, tool steel ...

0086-813-8127573

0086-813-8127573