Product Informational Videos – Martinez Tool Co. - titanium speed square

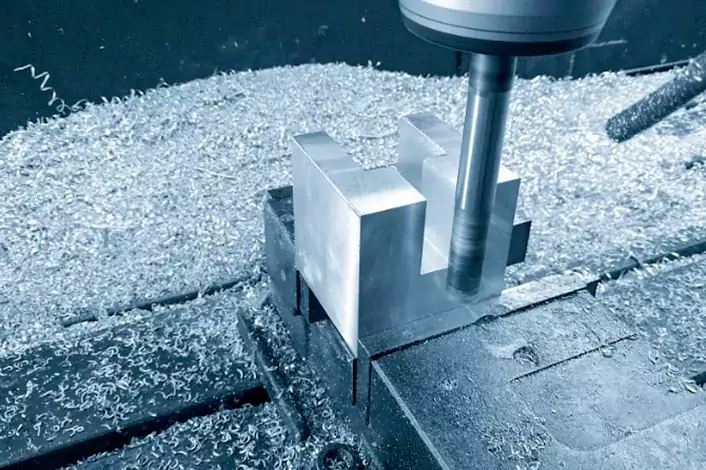

CNC machining involves the use of drills and turning tools to remove material from a solid block of material, creating a part. It’s a conventional manufacturing method that enables fast and highly precise production of parts with tight tolerances. This versatile process can be applied to a range of rigid materials, including plastics, metals, and fiberglass, with aluminum being a favored material for product development teams.

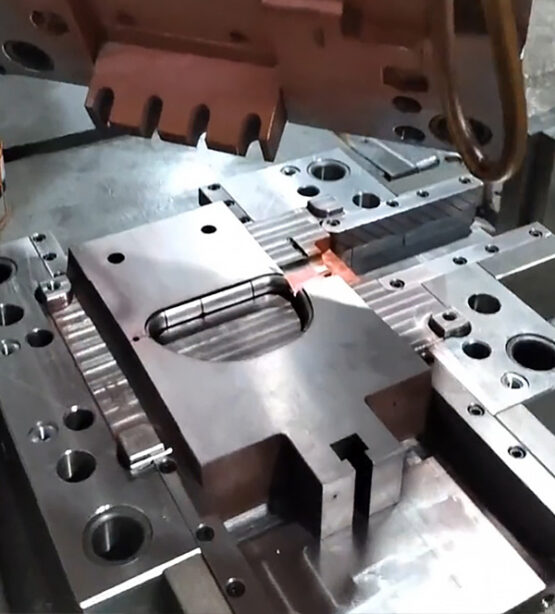

An “injection cycle” can refer to different processes depending on the context, but one common meaning of injection cycle is...

Nickel metal

At least 26 radioisotopes of nickel have been found. The most stable radioisotope is 59Ni which has a half-life of 76,000 years. Nickel also has one meta state.[1]

The most commonly utilized aluminum grade in CNC machining is known for its exceptional processing capabilities, high toughness, good mechanical properties, good corrosion resistance, absence of deformation post-processing, easy color film formation, and excellent anodizing effects. It is one of the most common aluminum alloys used in the industry. This aluminum grade is used in various industries, including truck manufacturing, building construction, shipbuilding, tram manufacturing, furniture production, precision machining, and a broad range of industrial applications.

Nickel is used to make many products like stainless steel, alnico magnet, coinage, rechargeable batteries, electric guitar strings, microphone capsules and plating on plumbing fixtures.[3] It is used as a green tint in glass.[4]

Nickel is got by mining: the ore is roasted and reduced. This gives a metal of over 75% purity. In many stainless steel applications, 75% pure nickel is usable.

The machinability of different aluminum alloys is primarily determined by their composition, making certain alloys more appropriate for specific applications. It’s worth noting that the addition of other elements has a significant impact on an alloy’s physical properties, such as strength, ductility, and corrosion resistance. Hence, understanding these properties is crucial in determining the suitability of the material for a given part.

The 3003 aluminum alloy belongs to the wrought aluminum-manganese family, which is also known as the 3000 or 3xxx series. This type of alloy can be cold-worked to achieve tempers with increased strength but reduced ductility, as it cannot be heat-treated like some other aluminum alloys. Its properties are similar to those of other aluminum-manganese alloys, as it is a versatile alloy that possesses moderate strength, good workability, and excellent corrosion resistance. Although it can be rolled and extruded, it is not typically forged, and it is not suitable for casting due to its wrought nature. Sheet metal applications such as gutters, downspouts, roofing, and siding commonly use this alloy.

nickel是多少钱

Aluminum 2024-T4 is a moderate- to high-strength alloy that offers good fatigue resistance and fracture toughness. It isn’t as strong as 7075-T6, but it’s still suitable for aerospace applications.

Aluminum alloys are classified into three groups: commercially pure aluminum, heat-treatable alloys, and non-heat-treatable alloys. While commercially pure aluminum is not commonly used in aluminum machining (although machine parts may use aluminum 1060), this article focuses on five alloys from the latter two groups.

Nickelsymbol

Although various metals can be machined using CNC machines, aluminum’s distinctive properties have made it a popular choice for CNC machining purposes. Aluminum alloy comes in different grades, and each aluminum alloy is best suited for specific applications.

MIC 6 Aluminum possesses a unique combination of alloy and casting methods, specifically designed to produce stable, high-tolerance plates. Its exceptional stress-relieving properties, accuracy, and machinability make it a highly sought-after option for machining components, electronics, and laser technology. Additionally, it is contaminant- and porosity-free, providing a smooth and lightweight choice.

Alloys are metals mixed with other metals or non-metallic elements. For example, aluminum alloys, which are mostly aluminum and other elements like iron, copper, and magnesium, are often used in machining.

Nickel is found in both laterite and sulfide ores. They are heated to melt them and concentrate them. They are also separated by oils. Nickel is made from its sulfide by heating it in air. This oxidizes the sulfide to sulfur dioxide, leaving liquid nickel behind. This nickel is not yet pure and not ready for use.

In recent years, the fusion of machine learning and artificial intelligence (AI) with CNC machine tools has revolutionized the manufacturing landscape.

Nickel was found when an ore that looked like copper did not make copper metal. Later it was found that the ore actually had a new metal, called nickel. Nickel was isolated as a metal and classified as a chemical element by Axel Fredrik Cronstedt in 1751. At first, the copper colored nickel ore was the only source. Later, it was made as a byproduct of cobalt blue making.

63Ni is used in krytron devices as a beta particle emitter to make ionization by the keep-alive electrode more reliable. Raney nickel is used for hydrogenation of unsaturated oils to make margarine.[8]

AA7075 is an aluminum alloy that contains zinc as its primary alloying element. This alloy possesses outstanding mechanical properties and demonstrates high ductility, toughness, and strength, along with good resistance to fatigue. Despite its susceptibility to embrittlement due to microsegregation, it has better corrosion resistance than alloys from the 2000 series. It has the strength same as mild steel but 1/3 of the weight. It is widely used in highly stressed structural applications, particularly in aircraft structural parts, making it one of the most frequently used aluminum alloys.

Nickel (chemical symbol Ni) is an element. It has an atomic number of 28 and an atomic mass of about 58.69amu. It has 28 protons. It is a transition metal.

Traditional automobile production processes are stamping, welding, painting, and assembly in 4 steps, generally, the steel plate is stamped into small parts

Nickel is found in two oxidation states: +2, nickel(II); and +3, nickel(III). Nickel(II) is more common. Nickel in its +2 oxidation state is green. Nickel(II) chloride is a common +2 oxidation state compound. Nickel(II) oxide is normally dark green, but sometimes it is gray. This is because some of the nickel is in the +3 oxidation state (nickel(III). Nickel(III) compounds are oxidizing agents. They also are grayish. Nickel compounds can be green, blue, gray, or black.

Nickel and its alloys are used as catalysts for hydrogenation reactions. Nickel is used as a binder in the cemented tungsten carbide.[7]

Nickelion

The isotopes of nickel range in atomic weight from 48Ni to 78Ni. Nickel that is found in nature is made up of five stable isotopes; 58Ni, 60Ni, 61Ni, 62Ni and 64Ni.

Nickel can irritate skin. That is why jewelry that releases nickel ions is bad for some people. Some nickel salts are carcinogens. Nickel is not as toxic as other metals such as mercury but it is still toxic.

Nickel is normally found as a mineral, and not as a metal in the ground. Sometimes meteorites have nickel and iron metal in them. The most common nickel mineral is pentlandite. Most of the nickel on Earth is thought to be in the Earth's Earth's outer and inner cores. There are sulfidic and lateritic nickel ores. Philippines mines the most nickel. Other major mining countries are Russia, Canada and Australia. All the older rocks on Earth have some rare metals. They are got by mining where the ores are most plentiful.

nickel中文

Strong, workable, and corrosion-resistant, Aluminum 5052 — made with magnesium and chromium, amongst other components — is widely used in marine applications because of its resistance to saltwater. It is also the strongest non-heat-treatable alloy available. Aluminum 5052 sheets have enough strength for most applications while not too brittle to break when bending, they are probably the most common aluminum sheets used in sheet metal fabrications.

This material is particularly well-suited for general-purpose applications that require increased strength and toughness, with widespread use in the construction industry in bridges, towers, and trusses. However, designers should note that it’s challenging to create thin walls using aluminum 6082.

The most common methods of cold working and strain hardening involve rolling, drawing through dies, stretching, or other similar operations that result in an area reduction. The final properties of the alloy are determined by the total area reduction of the material. Additionally, “stabilizing” is a process carried out at elevated temperatures that ensures that the final mechanical properties of the alloy remain consistent over time.

Nickelatomic mass

Rapid tooling primarily serves the product development and manufacturing processes in two main ways

Heat-treatable alloys are comprised of a combination of metallic and non-metallic components, including pure aluminum that is heated to a specific temperature before alloying elements are added uniformly. This addition of alloying material causes the aluminum to solidify, albeit still at a high temperature, after which it is rapidly cooled through quenching. This rapid cooling can cause the atoms of the alloy elements to solidify in place.

Pure nickel with a nickel content greater than 99% is made in an electrolytic process. In this process, the nickel is dissolved in bath of sulfuric acid. When the pure nickel sticks to cathodes hanging into the bath, the impurities remain in the sulfuric acid or at the bottom of the bath. These impurities are very interesting, as they can contain precious metals.

Nickel is a silver-white metal. It is easily polished (made shiny). It is magnetic. It is not magnetic when heated above 355 °C (671 °F). It is not soft like many other metals. It can be stretched into wires easily. It is not radioactive.

nickel是什么

Aluminum alloys that are not heat-treatable are created by combining aluminum with alloying elements prior to any heat treatment. The initial strength of these alloys is achieved through the addition of these elements. Non-heat-treatable alloys include pure aluminum alloys, manganese alloys, silicon alloys, and magnesium alloys. To further enhance the strength of these alloys, various cold-working and strain-hardening processes are utilized.

Nickel is not a reactive metal. It dissolves slowly in acids. It does not rust like iron. It makes a thin coating of nickel(II) oxide which stops more corrosion. Aluminium does a similar thing.

However, compared to 6061 Aluminum, MIC 6 threads are not as strong, especially with fine threads that may result in premature thread failure. Therefore, designers should be mindful of this limitation during material selection.

Common applications for aluminum 2024-T4 include aircraft fuselage, transport vehicle parts, and wing tension members. However, product teams should note that this grade of aluminum has poor corrosion resistance and is highly sensitive to thermal shock.

In conclusion, the wide range of aluminum alloys available for CNC machining provides engineers with a diverse set of options for different applications. The selection of an appropriate aluminum alloy depends on various factors such as strength, flexibility, corrosion resistance, and machinability, which are significantly influenced by the composition of the alloy. Therefore, understanding the properties of each alloy is crucial in selecting the ideal material for a given part. The commonly used aluminum alloys in CNC machining include heat-treatable alloys and non-heat-treatable alloys, with different physical and chemical properties. By taking into account the characteristics of each alloy, manufacturers can produce high-quality, efficient, and cost-effective machined parts for various industries.

Nickel(II) compounds are not highly reactive. They are normally green or blue. They are toxic and irritate skin. Some of them are carcinogens.

Sixty-eight percent of all nickel produced is used to make stainless steel. Nickel is also used in nichrome, a name for a nickel-chromium alloy, and other alloys. Nickel is used in magnets. Nickel is used in special expensive alloys called superalloys.

Nickel

Nickel sulphate is used in rechargeable batteries. A lithium ion battery contains up to 15% of nickel while the lithium content is less than 1%. A nickel cadmium battery also uses nickel. Nickel compounds are also used to electroplate nickel on items. Nickel and some of its compounds are also used as a catalyst. Nickel is used in stainless steel. It is also used in some nonferrous alloys. It is used in electroplating.[2]

Aluminum 6082 boasts properties similar to aluminum 6061, with slightly higher tensile strength. It holds the distinction of having the highest strength among all the 6000 series alloys, in addition to excellent corrosion resistance. For engineers seeking greater strength than that provided by 6061 but not keen on investing in the 7000 series, 6082 is an attractive option.

5-axis machine Aluminum Extrusion Atomic Layer Deposition Automation in Injection Molding black oxide finish Chemical Vapor Deposition CNC Machine CNC machining CNC Milling CNC Prototyping Compression testing Designs for Injection Molding DFM Extrusion Welding Fatigue testing Friction Spin Welding Friction Stir Welding Gas-assisted Injection Molding Hardness testing High Pressure Die Casting Injected Material Injection Mold Injection Molded Liquid silicone injection molding Make Plastic Molds Medical CNC Machining Metal 3D Printing Metal injection molding Multi-shot Injection Molding Physical Vapor Deposition Plasma Electrolytic Oxidation Plastic Injection Defects plastic injection molding Powder Metallurgy Powder Metallurgy process Rapid Injection Molding Screen Printing Selective Laser Melting Shore Hardness Simulation Software Six-Axis Robots Surface finish Urethane Casting Vacuum Casting Waterjet Cutting

Typically, heat-treatable aluminum alloys form as the aluminum atoms and alloy element atoms naturally combine during the aging process at room temperature. However, in some cases, this process is artificially induced through aging in a furnace set at a low temperature.

0086-813-8127573

0086-813-8127573