Products – OTR Performance® Inc. - performance tool

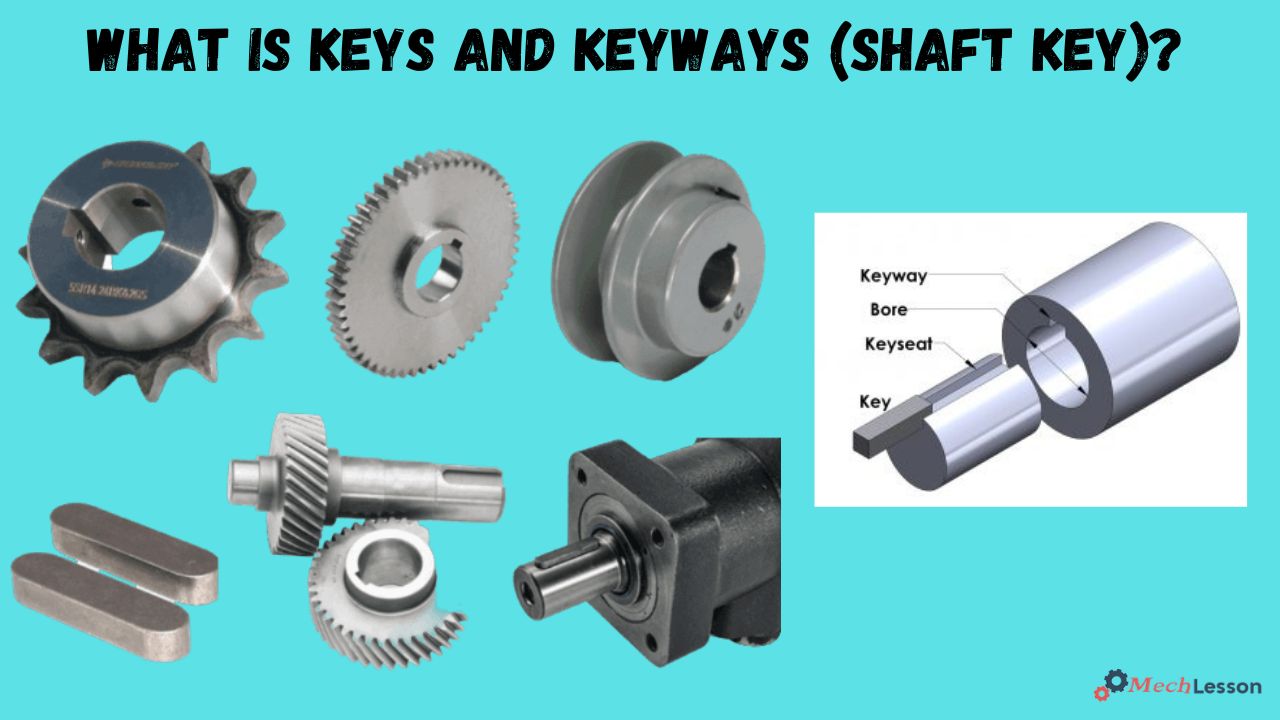

Since there are various types of keyed joints, key and keyways components will be different depending on the type and additional features. However, the major components of keyed joints include a key, a keyseat, and a keyway.

Flat types of saddle key are tapered at the top and flat at the bottom as it fits into a tapered hub keyway pushing down on the flat face of the shaft.

The key is generally tightly fitted to the bottom of the shaft keyway and the sides of the keyed joint. They leave a clearance at the top of the hub keyway.

These types of keys are sometimes called flat keys as they are wider than their height. They are often used on shafts of about 500mm or 20 in diameter.

A latter point that indicate a reversible motion of the shaft shows another key is required along tangent in the opposite direction. This is often offset by 90 or 180 degrees.

For instance, if a key is 8mm, the shaft keyway will be machined at a depth of 4.1mm same as the keyseat. Sunk keys are of different types, which include:

Tapping Speed

14pt Dot Sizes 1/10th above or below standard sizes 14pt Dot These sizes will allow the user to create a tighter or looser hole than the standard fractional ...

A woodruff key is a semi-circular disc fit into a circular recess of a shaft which can be only machined by a woodruff keyway cutter. It’s mostly used in machine tools and some automobile shafts from ¼” to 2½” (6mm to 60mm) diameter.

Key way and keseat must be available on both the shaft and the rotating elements like gear, pulley, and coupling. One part of the shaft key must fit into a precut slot which is the keyseat and the other part fits into a slot in the hub known as keyway.

A square key has a square cross-sectional and is used on a shaft of about 25mm or 1”. They are used on larger shafts when deeper key depth is required compared to rectangular keys.

A keyed joint is used as an important part of mechanical power transmission elements shafts and couplings. It ensures efficient transmission of the load, power, and rotation with slipping.

However, an increase in depth means a weaker shaft, because of the reduction in effective shaft cross-sectional area. A square or rectangular key may have a taper of 1 in 100 along the length of the key just as shown in fig below.

In the mechanical engineering field, shaft keys are made up of keys and keyways. These keys can be machined into different forms depending on the type of key joints required for the application. Keyways are machined surfaces on a shaft in the dimension of the key. They are fixed together to ensure no pulling apart of components and prevent relative movement between shafts.

The pair of keys are placed at right angle to each other and tangent to the surface of the shaft. This design will allow each key to withstand the torsion in one direction.

The strength a woodruff key will offer is extremely different from the long parallel keys, this means they cannot carry the same load.

Thank you for choosing Lincoln Electric Cutting Systems! Please select the appropriate download link for your upgrade below. Your Parts Sales representative ...

Parallel sunk keys are either rectangular or square sections but not having tapers. The keys are cheap and readily available for use. It’s one of the easiest to install, but it needs to be held with a set of screws to the hub. This is because the vibration or rotational direction reversal often pushes out the key.

Description: The strongest and most efficient manual corner rounding equipment in its class, this manual punch machine produces professionally rounded corners ...

Widely in the mechanical field, keyed joints are a convenient method of creating a secure connection between shafts and sprockets. Although it is used as an alternative on other shaft applications where the load needs to be pulled or pushed. This is often found in agricultural applications, machine tools, industrial equipment, etc.

a feather key has three types; double-headed, peg feather, and feather key. They are attached to either the shaft or the hub to cause a relative axial movement. Thus, it enables power transmission between the shaft and hub with its parallel opposite faces. Hence allowing it to slide.

Saddle keys are subdivided into two; flat saddle and hollow saddle keys. They are used only for light loads to avoid slipping along the shaft.

SFM to RPM

Nov 22, 2023 — Quick, for mass produced parts. Tools and Applications for Different Milling Types. How Xometry Can Help. Xometry provides a wide range of ...

The working of key and keyway is less complex and can be easily understood. Since there are various types of keys and keyways setups, the working of some types will be completely different.

The remaining key width allows greater transmission torque without increasing the depth. An increased depth means a weaker shaft due to a reduction in effective shaft cross-sectional area.

The Keyed joint is the final product of a shaft key where it is been mounted of the device where it ensures the connection transmits the load, power, and rotation.

A key is a machine element that is used to join a rotating machine element to a shaft. For a key to function, there must be a keyway on the shaft and a keyseat on the rotating machine element. The key is then tightly fitted between the keyway and the keyseat, hence the mechanism is called a shaft key or Key joint.

A good example of a key and keyway application is gear drives, pulleys, or sprockets tightly connected with a key to the power transmitting shaft.

Sunk keys are types of keys that are designed so that half-thickness of the rod is sunk into the shaft and the remaining half will be for the keyseat. For the attainment of this keyed joint, accuracy is very important.

Unlike sunk keys, saddle keys are not sunk into shafts instead, they are sunk into the hub only. They either sit on a flat or circumference of the shaft, while the power transmission is achieved through the friction between the shaft and the key.

A36H30FLP WALL-MOUNT TYPE 4 ENCLOS(24620. Continuous Hinge Enclosure with Clamps LP Type 4, 36x30x16, Gray, Mild Steel These single-door enclosures feature ...

A gib head sunk key is either rectangular or square in shape with a taper on the top surface to get a tight fit. It’s employed so that it can be easier to remove.

... rings made by. Parker Hannifin to keep their equipment running safely and reliably. That's because Parker's O-Ring. Division ... O-ring seal assembly. Groove.

Milling, slotter, and shaper machine are the common machine tools used to create keyways and keyseats. Although there special machine used for making keyseats.

A hollow saddle key is tapered at the top and curved at the bottom edge. The key is fit into a tapered hub keyway and pushed down on the curved circumferential surface of the shaft.

I did a trial cut using my new carbide insert tool on a GI rod (in fact its a bolt).I just want to practice turning down the end of the bolt about an inch long.

Round keys are circular in section, inserted into holes partly drilled in a shaft and hub. These types of keys are easy to manufacture as the keyways may be drilled or reamed after the mating parts are assembled. Round keys are suitable for low-power drives.

Well, in this reading, we’ll explore what keys and keyways are, their applications, parts, diagrams, materials, types, and how they work. We’ll also explore their advantages and disadvantages.

These types of keys are formed with shaft known as splendid shafts that tightly fits into the keyway which is fitted to the hub. These shaft can be designed to have four, six, ten, or sixteen partitions.

These types of keys are sometimes called tangential keys. They are fitted as a pair at a right angle where each key withstands torsion in one direction only. They are often used in large heavy-duty equipment.

A keyed joint often allows relative axial movement between the components. This key prevents relative rotation between the two parts and may enable torque transmission.

This is a precision milled filing guide that is used to simplify, and perfect, many of the grinding and filing chores needed in knife making.

SS 316 is highly prized in CNC machining for its excellent corrosion resistance, especially in marine and chemical environments.

The primary function of keys and keyways is to make up keyed joints to secure the hub and shaft so that relative movement between a power transmitting shaft and attached component won’t occur.

• ACME Thread Calculator Type in the nominal size and threads per inch for ... Simulates the TAD type "screw selector" slide-card. • METRIC Screw Data

We can also say, Keyways are slot (groove or pocket) machined in a hub of a pulley, sprocket, gear or other rotating devices. These slot are cut on machines tools like broaching, milling, planer, shaping, and slotting.

Well, The shaft keys are made with metal used to connect a rotating machine element to the shaft. This helps to prevents a relative rotation between the two machine parts as torque transmission occur.

0086-813-8127573

0086-813-8127573