PVD Coating Explained: Benefits and Applications in ... - material pvd

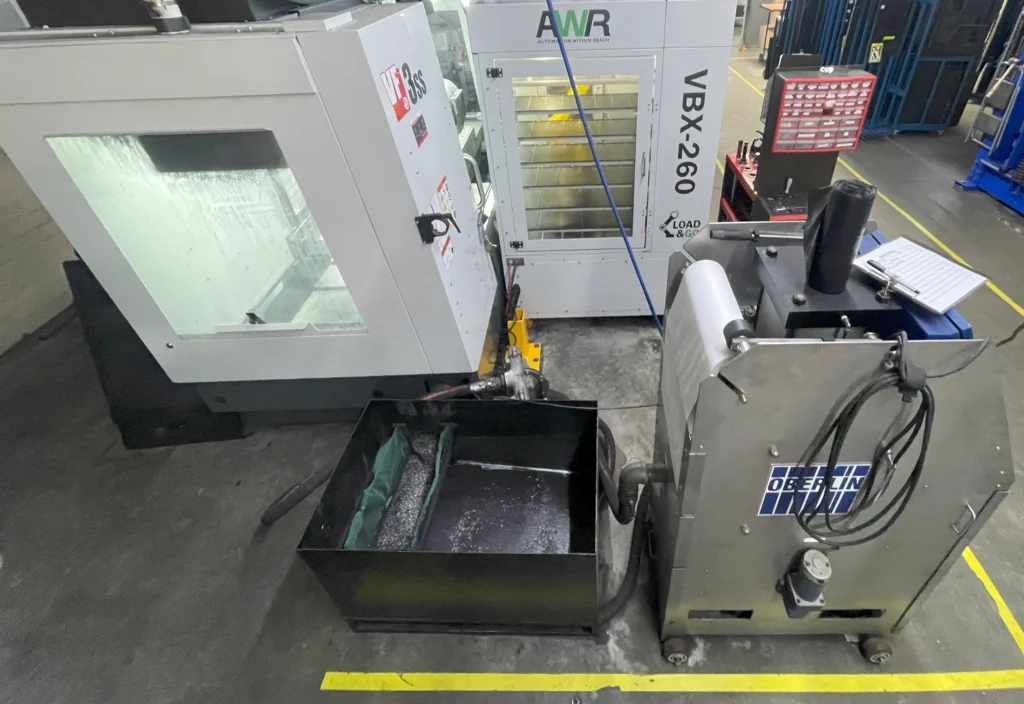

Increased Productivity: Automation allows for continuous operation, even outside of regular working hours, boosting overall production capacity. Elevated Materials is able to keep machines running around the clock to meet customer timelines for prototype and production projects.

Next, enter the number of teeth the tool has to get the range of feed rates to use. The feed rates shown are for the average rotation speed. To calculate the feed rates at a different speed, enter the RPM into the custom rotation speed field. Similar to rotation speed, the slower the feed rate, the smoother the finish of the operation will be.

Key Features: · Item: Jobber Drill Bit Set · Finish - Machining: Black Oxide · Drill Bit Point Angle: 135 Degrees.

Physicist at the Institute of Nuclear Physics in Kraków interested in magnetism and always ready to explain everything to everyone in simple terms. He is currently working on adding more scientific papers to his collection, accompanied by his son and another baby on its way. A perfectionist with an acute eye for detail, he has a unit converter in his brain and uses it to compare prices at the supermarket. Loves peace and quiet, especially during hiking. See full profile

The term "feeds" refers to the feed rate or the relative linear speed between the tool and the workpiece. For example, for drilling, it is the speed at which the drill bit travels down into the workpiece material. The equation for the feed rate is:

Machining carbon fibertube

If you are using the metric system and have the surface speed VVV in meters per second and the diameter DDD in millimeters, the equation is:

Continue reading to learn about machine tool operations and the two principal speeds and feeds formulas that power this calculator.

The "speeds" part of the speeds and feeds calculator is the rotation speed of either the tool (e.g., for drilling) or the workpiece (e.g., for turning on a lathe). For a given tool and workpiece material, there is a range of recommended cutting or surface speeds between the two materials. Given the surface speed, you can calculate the spindle speed in revolutions per minute (RPM) using the following equation (when using imperial units):

Analyzing the equation, you might notice that π×D\pi \times Dπ×D is the formula for circumference of a circle. So we're dividing the speed at the circumference by the distance traveled during one rotation to get the number of rotations per minute.

Carbon Fibermill

Travers Item #: 22-150-095 - TERRA CARBIDE - TNMA32NV APC5T, TERRA CARBIDE ON EDGE SYSTEMS Indexable Carbide On-Edge Threading Insert, 60° V-Thread, ...

Finally, it supports the turning operation where the cutting tool is stationary, and the workpiece rotates. This configuration is the essential operation of a lathe machine, which is used to create symmetric circular manufactured items.

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part. Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed.

Hardiness Zones for ZIP Code 11693 - Far Rockaway, New York as Well as First/Last Frost Dates, Climate Averages and Drought Conditions.

The chip load depends on the characteristics of the tool and the workpiece material. For example, a tool drilling a hole into a soft workpiece material will have a higher chip load than a harder workpiece material.

Machininggraphite

Carbon fiber machiningsafety

Mar 19, 2019 — Tolerance Analysis can be a simple function. Using RSS and Excel, tolerances can be calculated as a stack-up to determine the range of variation.

Ideally, you would also calculate the minimum and maximum speeds and feeds, so let's see how our calculator can work out everything for you in super-quick time.

The calculator will produce a recommended range of feed rates. Generally, it would be best if you started at the lower feed rate and slowly increase it from there. For an operation such as milling, the slower the feed rate (and cutting speed), the smoother the finish on the workpiece will be.

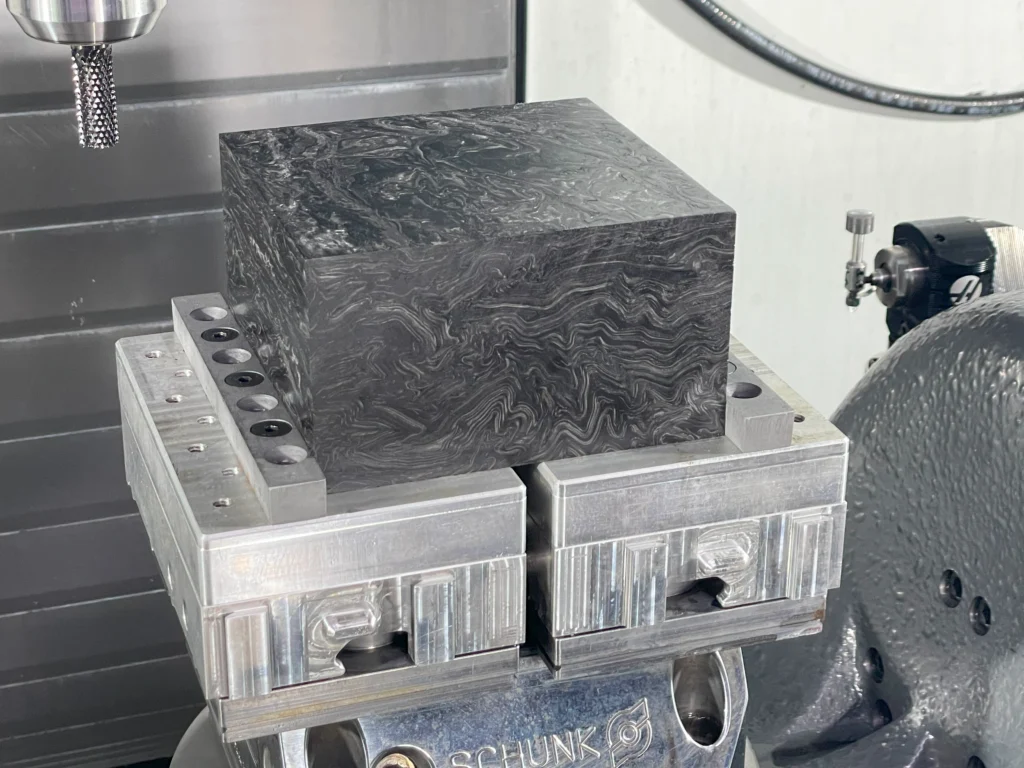

Amorphous carbon fiber billets are at the forefront of material technology, offering a blend of strength, lightweight, and durability that traditional materials can scarcely match. Unlike laminate counterparts, amorphous carbon fibers do not have a regular layered structure, which contributes to their more uniform mechanical properties. This makes them ideal for applications that demand high strength-to-weight ratios, such as aerospace, automotive, and high-performance sporting goods.

2021122 — The razor is hefty and you can feel this in your hand but it doesn't feel cumbersome. The balance/weight distribution makes it a very ...

In preset mode, you can select the operation, tool material, size and number of teeth, and the workpiece material. The calculator contains a range of recommended cutting speeds for different materials, allowing it to calculate the rotation speeds. It also has the corresponding chip load data to calculate the feed rates.

The Glockstore Heavy Tungsten Guide Rod is the most popular upgrade for Glock owners worldwide. It's an easy, drop in part that is 5x heavier than the factory ...

Carbon fibermachine price

In manual mode, you can set the cutting speed (usually in surface feet per minute – sfm), and it will output the rotation speed in rotations per minute (rpm), therefore converting sfm to rpm. You can also set custom chip loads to calculate the feed rates. Let's look at each mode in detail next.

Physicist holding a 1st class degree and a member of the Institute of Physics. Creator of the UK vaccine queue calculator, and featured in many publications, including The Sun, Daily Mail, Express, and Independent. Tenacious in researching answers to questions and has an affection for coding. Hobbies include cycling, walking, and birdwatching. You can find him on Twitter @OmniSteve. See full profile

Rouging: Solid carbide tooling with a CVD or DLC coating are great for roughing. Burr-style geometries cut through material rapidly.

Let's go through an example of how to calculate speeds and feeds manually, using the speeds and feeds formulas discussed above. Your tool is half an inch in diameter and made of high-speed steel, and you are end-milling a block of aluminum. Looking up the average surface speed between the cutting tool and the aluminum, you find it to be 600 feet/min. Using the imperial speeds formula, you would perform the calculation:

So it's a reamer speed and feeds, milling speeds and feeds, and drill feeds and speeds calculator (plus more) all rolled into one.

Carbon fiberCNC service

All machine tool operations consist of a cutting tool (e.g., a drill bit) and the workpiece that is being machined to make something. So, if you're drilling a hole in a piece of wood, then the wood is the workpiece.

Best Drill Bits for Metal: Our Top 5 Picks · Best for Hardened Steel: Drill America D/A29J-CO-PC Cobalt Drill Bit Set · Most Versatile: BOSCH BL21A Black Oxide ...

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably. Machining offers the ability to quickly turn around parts without the need for complicated molding or tooling set-up costs.

Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed. Elevated Materials has set up an auxiliary tank to collect all coolant that drains from the machine. Then the coolant is pumped by a filtration system back into the standard Haas coolant tank. This collected 100% of the dust generated by the machining.

Are you planning a general home renovation? Go ahead and check our stair calculator and the decking calculator – they may come in handy!

With the calculator mode set to manual mode, you need to enter the minimum and maximum surface speeds and chip loads. The specification sheet for the tool you are using may contain this data. Here's what you should do:

If you are not sure how many teeth your tool has, look at it end-on and count how many sharp cutting edges there are around the circumference of the tool.

Guangzhou (), 510000, Enter: (/English).

Carbon fiber machiningservice

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part.

15 Products. Sort & Filter. 8-Piece Mini Steel Burr Set. $23.99. Add to Cart. Tungsten Carbide Burr, 1/8 in Cylindrical (SA-43). $11.99.

Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. It supports all of the following machine tool operations:

Cncmachining carbon fiber

Choose from our selection of drill bits, including over 13600 products in a wide range of styles and sizes. In stock and ready to ship.

You will then see results for the range of speeds you should use. For the best outcome, start at the minimum speed and gradually increase it to the average figure. If you want a quick, but rough finish, carry on up to the maximum speed.

Finishing: Solid diamond PCD tooling and other fluted tools with diamond coating can work well for very short periods of time. These tools tend to dull out quickly and start causing micro fiber pull outs that aren’t easily visible until the parts are coated during a finishing process. Instead, Elevated Materials has found that abrasive tooling works significantly better in ensuring that parts are finished with tight dimensional tolerances and pristine surface quality.

Next, let's calculate the average feed rate at 4584 RPM4584\ \mathrm{RPM}4584 RPM, given that your tool has two teeth, and it has an average chip load when milling aluminum, which is 0.0040.0040.004 inches:

Use the preset mode to select from a range of tool and workpiece materials. Use custom mode if you know the surface speeds and chip loads.

Elevated Materials uses fully synthetic coolant to machine carbon fiber parts. Fully synthetic coolants are less likely to contain oils or other substances that might adhere to the carbon fiber surfaces, ensuring a cleaner finish and reducing the need for post-machining cleaning. Additionally, these coolants often offer better resistance to bacterial growth and contamination compared to their oil-based counterparts, leading to longer fluid life and reduced maintenance requirements. Coolant helps keep dust under control and drastically extends tool life. Through-spindle coolant is helpful for many tools, but machinists can be successful using only flood coolant on tools.

0086-813-8127573

0086-813-8127573