"Quick Cut" Thread Cutter - thread cutter

In general, tungsten high-speed steel has a high tungsten content and minimal molybdenum presence. Despite notable technological advancements and material innovations, improving the performance of cold machining tools still relies on time-tested metallurgical principles that have served tool and die shops through generations.

What ishss used for

Factors such as temperature and time must be carefully controlled to ensure quality, as variations can lead to expansion or contraction in the final product, affecting its mechanical properties.

High-speed steel is a special type of tool steel known for its exceptional hardness, toughness, and superior heat resistance. To understand more about it, the following article from Stavian Metal will delve into the details of its composition, characteristics, and diverse applications. Let’s dive in to gain valuable insights.

High speed steel grades

Heat treatment is an important aspect of high-speed steel production, including stages such as annealing, austenitization, and martensitic transformation. Annealing reduces hardness, followed by austenitization, in which high temperatures alter the crystal structure to absorb carbon.

Choosing to use cobalt high-speed steel is rational when deep cutting and high cutting speeds are required or when dealing with hard materials. Additionally, M42 has high heat-treated hardness (68 to 70 HRC) and a significant cobalt content, providing exceptional hot hardness. Therefore, tools made from M42 high-speed steel maintain sharp and hard cutting edges, making them ideal for heavy cutting and high-production applications.

High speed steel properties

Currently, high-speed steel is challenging to find on the market due to its relatively high cost. However, if you have the need, you can contact Stavian Industrial Metal Corporation. This is a reliable, reputable source with reasonable pricing.

The extended tool life makes it suitable for cold machining tools. M4 and T15 are becoming popular for milling cutters due to ease of sharpening and regrinding. What sets T15 apart is its significantly higher vanadium content compared to other types of high-speed steel.

High-speed steel undergoes a series of meticulously controlled steps to achieve its special properties. It begins with refining and alloying the steel, followed by forging and rolling into marketable forms.

What isHSS in government

For those seeking improved results, it’s essential to review three critical aspects: material selection for tooling, precise heat treatment processes, and surface quality preservation.

What isHSS medical

Tungsten high-speed steel is a member of the “T” alloy family. It contains 17.25 – 18.75% tungsten, along with chromium, vanadium, and carbon. Notably, T15 with 5% cobalt exhibits wear resistance, toughness, and corresponding flexural strength.

Most products provided by Stavian meet customer needs. Therefore, you can rest assured when choosing Stavian. For more information, please contact:

Cobalt high-speed steel is an alloy with over 5% cobalt, making it superior in hot hardness and wear resistance. Typically, these types of steel contain tungsten, chromium, molybdenum, vanadium, and high carbon content. Notable grades in this category include M35 and M42.

Molybdenum high-speed steel, such as M10 and M50, is an iron-based alloy known for its exceptional strength and cutting ability. Furthermore, M10 and M50 are exclusive types in the molybdenum high-speed steel category that do not contain tungsten or cobalt. Its excellent flexural strength and wear resistance make it useful in various tool applications, including drill bits and reamers.

Tungsten-molybdenum high-speed steel, such as the “M” alloy series (M1, M2, M3, M4, M7, M52, M62), is distinguished by its composition, primarily containing tungsten (W) and molybdenum (Mo). Unlike some other types of high-speed steel, they do not contain cobalt (Co).

What ishss metal

High-speed steel, formed from a superior iron alloy, stands out in cutting applications compared to traditional high-carbon steels. This steel possesses special characteristics of hardness, wear resistance, and softening resistance at high temperatures. These characteristics, achieved through the addition of alloying elements and special heat treatment processes, enable high-speed steel to efficiently and quickly cut materials. The technical symbol for high-speed steel is HSS.

What isHSS in construction

The cost of high-speed steel varies depending on the specific type and grade. For example, tungsten high-speed steel (T1 HSS) may range from 194,000 VND to 242,000 VND per kg, while M35 high-speed steel can fluctuate from 1,938,000 VND to 21,834,000 VND per kg.

What ishigh speed steel made of

Thus, the above article has provided valuable information about high-speed steel. Hopefully, you will have many experiences and effective applications of this type of steel.

These types of cobalt high-speed steel are highly effective for demanding tasks such as rough cutting or interrupted cutting, excelling in high-temperature-related applications. However, they are less suitable for finishing cuts at lower temperatures. Their superior performance shines when cutting continuous materials such as cast iron or non-ferrous metals.

These alloys offer similar advantages to tungsten-rich alloys but focus on reducing weight due to the lower density of molybdenum. While these alloys have reduced tungsten content, they compensate with higher molybdenum ratios.

However, it’s noteworthy that the melting point of these alloys is lower compared to those with higher molybdenum content. As a result, they may experience reduced hardness retention when hot compared to tungsten-rich alloys due to decreased heat resistance at high temperatures. This is a trade-off to consider when selecting suitable high-speed steel for specific tooling applications.

Martensite forms when steel is rapidly cooled, making it hard but brittle. HSS is a carbon and iron alloy, with additional elements added to create specific properties. Molecular transformation through heat treatment will rearrange the atomic structure, providing the desired properties to the steel.

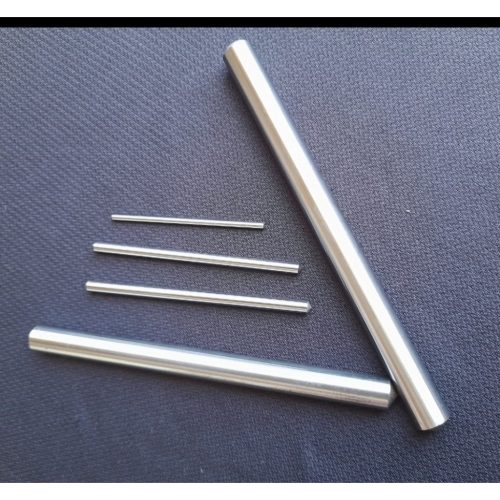

The characteristics of high-speed steel include superior hardness and wear resistance. This makes the group of high-speed steel alloys a popular choice for industrial cutting tools, including milling cutters, drills, reamers, saw blades, taps, and drills. Different types of high-speed steel alloys provide users with various ways to balance strength, toughness, hot hardness, and wear resistance.

Molybdenum high-speed steel is mainly an iron-based alloy distinguished by its notable combination of molybdenum, with a relatively higher concentration compared to other types of high-speed steel. Additionally, it contains a significant amount of carbon, usually ranging from 0.8 to 1.5, depending on the specific type, as well as many other elements known for their carbide-forming characteristics.

This process demands precision and uniformity at each stage and involves steps such as preheating, quenching, and annealing. Depending on the type of steel and its intended use, additional processing methods such as cryogenic treatment may be necessary to achieve desired properties.

0086-813-8127573

0086-813-8127573