Quick Turn Clothing: Home - quickturn

Answer: A round-over bit is used to round over sharp edges on shelves, tabletops, chair arms, and other woodworking projects, providing a decorative and safe finish.

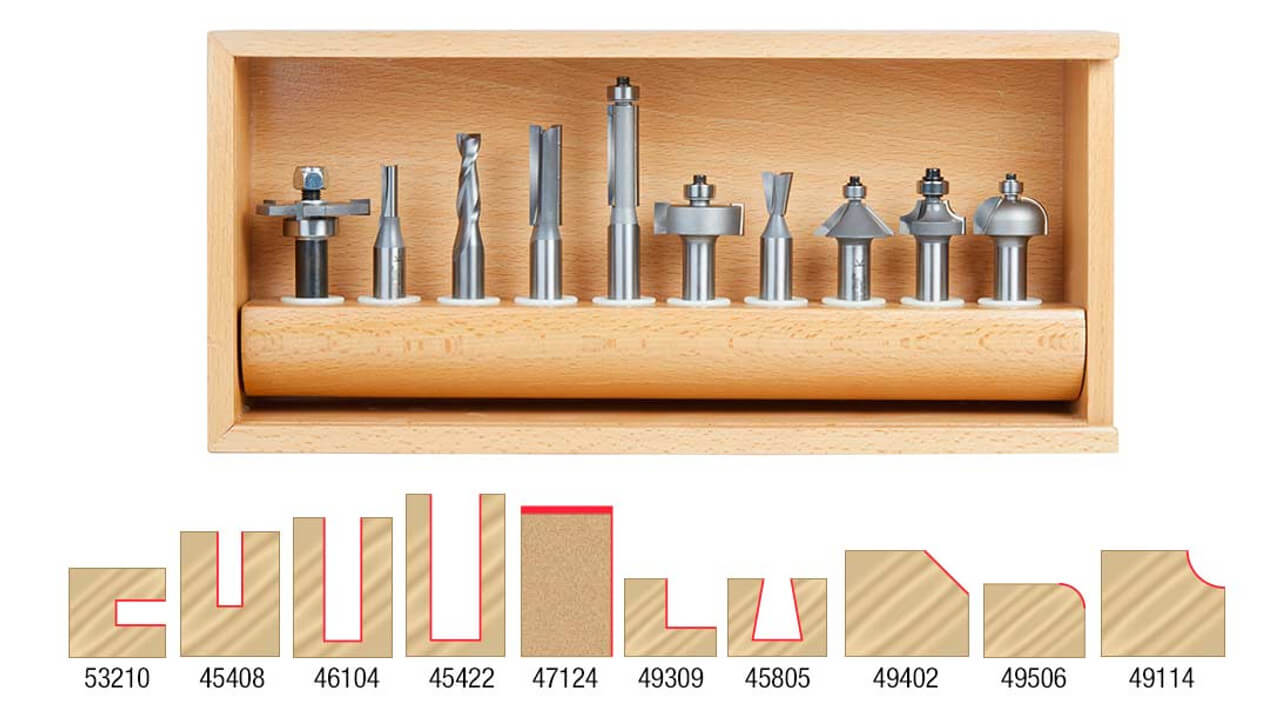

(Well. It's really the top-11 if you count straight-plunge and spiral-plunge as 2 different types. But they basically do the same thing.)

That was a very abbreviated tour through the ISO 1832 standard, now on its sixth edition and spanning 24 pages. You’ll find it a helpful starting point on your road to insert selection.

One other note: Make sure you get the right shank size. While you can use a collet adapter to fit a 1/4" shank into a 1/2" machine, 1/2" shank bits are considerably stronger and provide a safer, smoother cut.

Turninginserts types

Indexable tools make machine setups faster and easier while significantly reducing the downtime associated with tool changes, but choosing the best insert can be tricky. Here’s what you need to know.

A good place to start is by learning the ISO 1832 standard, which, according to the International Organization for Standardization, “establishes a code for the designation of the usual types of indexable inserts for cutting tools in hard cutting materials or any other cutting materials, in order to simplify orders and specifications for such inserts.”

Unlike a Flush-Trim, the pilot is deliberately not the same diameter as the cutting edge. The difference creates the precise depth of the rabbet.

These bits feature a rounded tip that is ideal for creating smooth, rounded grooves, slots, and intricate carvings in both softwood and hardwood. The core-box bit's design includes fluted edges, which allow for efficient removal of material and help to minimize burning and improve the finish quality. Ideally carbide-tipped for durability, these bits come in various diameters, enabling precision and versatility in creating decorative details or functional features like channels for wiring or pipework.

When you get your first router, the best way to explore is to get a small set with a variety of router bits, and see which ones you use over and over, and, what other bits you need to supplement your set. The general-purpose AMS-410 is an excellent choice.

Kip Hanson is a freelance writer and manufacturing consultant. Hanson, who is the proprietor of KAHMCO LLC, has more than 40 years experience in manufacturing, machine tools, fabrication and ERP systems. In addition, Hanson is a contributing editor at Manufacturing Engineering, Shop Metalworking Technology and others. He has been writing about manufacturing technology since 1998.

Answer: A slot-cutting bit is used to cut narrow slots or grooves in various woodworking projects like cabinet door frames, floorboards, picture frames, and drawer parts. It is also ideal for cutting spline grooves for spline joints.

Known for its elegant profile, the Ogee bit is a popular choice among woodworkers. It creates a decorative edge that adds a touch of sophistication to any woodworking project.

Round-over bit is a versatile tool that can add a professional touch to woodworking projects. Whether you are creating custom furniture or adding finishing touches to a DIY project, a round-over bit can help achieve smooth and rounded edges.

Spiral bits combine a shearing action in cutting, with an augering action in chip clearance. The shearing action yields an especially clean & accurate cut, while the augering action clears chips from the cut. The “up-cut” shears from the bottom up, pulling chips from the bottom up, thus allowing deeper penetration with less stress on the tool. The “down-cut” cuts from the surface down, leaving a smooth edge at the surface.

2. Dirt and dust particles will adhere to the oil hold and lead to unsmooth coolant flow. Coolant change as early as possible is recommended.

Carbideinserttypes

“Our 3D-printed Jetstream coolant clamps deliver cutting fluid to the correct location for different turning applications like heavy roughing, roughing and finishing,” he says. “They can also be used with our Steadyline brand of modular boring bars, which have an internal dampening mechanism to eliminate chatter, improve surface finish and increase productivity.”

Cut half-round grooves for fluted moldings, columns, millwork, and signs using a core box bit. Used with an edge guide, it can cut coves. It is perfect for juice groove in cutting boards.

For most turning operations, though, indexable carbide tools make machine setups both faster and easier while significantly reducing the downtime associated with tool changes. Which still leaves one problem: deciding which insert is right for the job.

Answer: A Roman ogee bit is used to create classical decorative detailing on the edges of tabletops, picture frames, vertical stiles, and horizontal rails, adding an elegant touch to woodworking projects.

Answer: The top 10 essential router bit types for a DIYer are straight- or spiral plunge bit, core box bit, v-groove bit, rabbeting bit, flush-trim bit, slot-cutting bit, round-over bit, 45-degree chamfer bit, cove bit, and the Roman ogee bit,

There’s just one caveat, though, and it applies to each of the proprietary solutions described here and elsewhere: Machine shops must invest in new toolholders, followed by reprogramming and process optimization.

“There’s a lot to consider during insert selection,” says Robert Keilmann, marketing portfolio manager at the company. “ISO turning tools are suitable for a great many applications, but given the huge variety of parts and materials in this landscape, not to mention the evolution of CNC machine tools, we’ve found it necessary to develop turning tools that provide effective chip formation and extended tool life on lower-horsepower machinery. Our FIX8 line does exactly that.”

Turning insertGuide

A Cove Bit, also known as a Cavity Drill, is a type of router bit used in woodworking to create concave grooves or decorative edges on wooden surfaces. It features a curved cutting edge that removes material as it rotates, resulting in a smooth and curved profile.

Trochoidal turning (also known by the trade names Dynamic Turning and VoluTurn) can be done with ISO-standard round inserts, but it’s more effective when the insert has a rail interface for graduated indexing, as with the company’s CoroTurn 107 RCMT.

Side note: for a really comprehensive list, check out our Router Bit Profiles Photo Glossary where we describe literally hundreds of different kinds of bits. Here we're going to concentrate on the most popular types - first with a quick list, then some details and pro-tips for using them.

A round-over bit is a type of router bit that is used in woodworking to create rounded edges and contours on the surface of a piece of wood. It's probably the most commonly used type of profiling bit. It is often used to soften sharp corners and give a smoother finish to the wood.

We continues to enhance our visibility and reputation, including exhibitions all over the world and we also actively taking corporate social responsibility.

Answer: A straight-cutting bit is used to cut straight, square-bottomed grooves, such as rabbets, dadoes, and grooves for plywood cabinet backs and drawer bottoms.

CNC machine

Straight bits are easy to use and provide excellent results when used with a router. They offer precision and control, making them a valuable tool for woodworkers of all skill levels.

These measurements provide an understanding of the different sizes available for Cove Bits and their corresponding dimensions. It is important to select the appropriate size based on the desired groove or decorative edge width.

A Flush-Trim Bit is a professional woodworking tool used to precisely trim the edges of any material to match the contour of another piece. It is commonly used for removing excess laminate flush with an underlying MDF substrate, or for precise copying of templates.

ZCCCT has been in the tungsten carbide industry for decades, the well-established management and production create the outstanding brand image in domestic market. Our CNC inserts are produced from most trusted and professional suppliers in the market. All the products are manufactured by using supreme quality metal and ultra-modern tools in compliance with set industrial norms. Moreover, we are using the strict tests on different quality parameters to assure the flawlessness at customer’s end. The competitive price will ensure our customers to stay competitive in the industry to create long-term cooperation.

Sandvik Coromant is not alone. Abhay Chaubal, product manager for the Americas at Seco Tools, is quick to point out that the company’s MF2 chipbreaker and RCMT insert solve the all-too-common chip control problem encountered when using round inserts.

Peruse a supplier’s tooling catalog or website and you’ll quickly find an overwhelming variety of indexable tooling. Profiling tools, groovers and threaders, boring inserts, indexable and modular drills, cutoff tools—there’s no shortage of high-quality turning tools out there, all designed to make lathe turning operations more profitable and part quality more consistent.

“The flip side of the FIX8 is that you can take much heavier cuts than with a WNMG- or CNMG-style rougher, and do so even on lighter-duty machines,” he says. “And since you have eight cutting edges to work with, the cost per part is generally lower as well.”

Hitting a home run might require thinking outside the ISO box, he says. “If you’re striving for consistent 15 percent to 25 percent increases in productivity, you should look at changing your whole process. Using trochoidal toolpaths during roughing operations is one such approach.”

“If we see that a shop can enjoy a 20 percent improvement in either tool life or productivity, we’re happy to present that to them in a written pre-sales test report and then prove it to them on the production floor,” Navarrete says. “Return on investment is generally quite fast when adopting a new tooling technology like this, with some customers saving tens or even hundreds of thousands of dollars. It’s pretty much a no-brainer.”

“One of the drawbacks of ISO standard tools is that they typically rely on a top clamp, eccentric screw or some combination of the two to hold the insert in place,” says Robert Navarrete, national product specialist for parting, grooving and turning. “Yet these can allow a microscopic amount of insert lift, leading to vibration and reduced tool life. A dovetail-style geometry and on-edge clamping system eliminate this by taking pressure off the screw and redirecting it into the pocket.”

Signing into Better MRO is easy. Use your MSCdirect.com username / password, or register to create an account. We’ll bring you back here as soon as you’re done.

Manufacturing Day events, including one hosted by MSC and its supplier partners, offer high school and college students hands-on experience with industry tasks, equipment demonstrations and opportunities to talk with professionals about career opportunities.

While choosing the right turning insert and toolholding system is critical, so is proper process development, says Seco Tools Indexable Product Specialist Jay McCord. Too often, shops don’t follow the manufacturer’s feed and speed recommendations and fail to use a scientific approach to troubleshooting, including documenting one change at a time.

Pro Tip: When using a Cove Bit, it is recommended to start with a smaller diameter bit and gradually increase to larger sizes if necessary. This approach helps achieve cleaner and smoother cuts, minimizing the risk of tear-out or uneven edges. Always make sure to secure the wood properly and use appropriate safety measures when working with router bits.

But considering that a new toolholder and box of inserts sell for a few hundred bucks or so, it’s a small price to pay for the potential benefits.

Product Name: CNC insert Application: All type of CNC machines Shape: Various shapes Quality level: High Surface: Coated or uncoated Trade terms: FCA, CPT, etc

CNCInserts

This versatile tool provides woodworkers with the ability to add unique details to their projects, giving them a professional and polished look. It allows for precise and clean cuts, resulting in high-quality finished pieces.

Ready for a quick ISO introduction? Pick up a “typical” box of turning inserts—some CNMG432 roughers, for example, or VPGR331 profiling tools—and follow along:

Like a Flush-Trim bit, a Rabbeting Bit uses a ball-bearing pilot to guide the cutting edge, to create a step-like recess called a rabbet on the edge or face of a wood material.

The Flush-Trim Bit is distinguished by its straight type design, with a ball-bearing pilot the exact diameter of the of the cutting blades, which guides the cutting edge exactly flush with the underlay material.

A V-shaped grooving router bit, commonly known as a V-groove bit, is a specialized woodworking tool used to create decorative channels or grooves on wood surfaces. V-grooves with very small angles such as 30° are commonly used as engraving bits. Follow these steps to effectively use a V-groove bit:

Like Winter, he encourages shops to explore alternative toolpaths, with ISO inserts or otherwise. He also notes that recent innovations in toolholding can bring significant results.

A straight-plunge bit, also known as a straight-cutting router bit, is an essential tool in woodworking. It is designed to create precise straight cuts in wood. Here are three key points to know about this tool:

VBMTInsert

Unfortunately, you’ll also find it chock-full of exceptions. In their ongoing effort to address the machining world’s ever-evolving landscape, cutting tool manufacturers continue to develop novel, often proprietary solutions that don’t fit neatly into any standardized set of guidelines.

“We’re also seeing great success with our PrimeTurning offering, which uses a similar chip-thinning strategy, as well as the eight-sided CoroTurn 800,” Winter says. “Yes, these solutions require some changes to your turning strategy but are well worth the time investment for shops that are working with difficult materials or looking for ways to leapfrog their competition.”

Answer: A cove bit cuts a concave radius out of the edge, providing a decorative edge that enhances the appearance of furniture legs, cabinet doors, and bookshelves.

Turning insertcode system

Navarrete is talking about Iscar’s HELITURN line of tangentially clamped turning tools. As he explains, these offer greater stability in the pocket, not only improving tool life and surface quality but also significantly increasing the tool’s metal removal capabilities. “It also provides much better predictability, an attribute that’s particularly relevant to shops that wish to run lights-out,” he says.

Smaller, handheld / trim routers typically typically accept only 1/4" shank. If that is your machine, opt for the AMS-134. You'll probably want to supplement with a flush-trim bit, but you won't have the power for a slot cutter.

A Cove Bit can be identified by its design, which typically includes a cylindrical body with a concave cutting edge. It's like the opposite of a round-over bit.

Keeping an assortment of brazed carbide tool bits and solid carbide rounds in the tool crib is probably a good idea. You never know when you may need to hand-grind a special tool for an oddly shaped part or hard-to-reach area.

A 45-degree chamfer bit is a woodworking tool that is used to create a beveled edge at a 45-degree angle on a piece of wood. It is typically used to add decorative edges or to create a smooth transition between two surfaces.

Machining inserts

Mitutoyo’s new profilometer, the SurfaceMeasure 1008S, can be integrated into an array of machine setups for a variety of measurement tasks. Find out how it can help you reduce waste and buoy productivity.

Iscar USA, a member of the IMC Group, is another cutting tool manufacturer pursuing continuous improvement opportunities for its customers, which is why the company isn’t afraid of setting aside the ISO 1832 standard when it makes sense.

“That’s one of the reasons why we’ve begun marking our inserts with QR codes, which allow the user to scan the code with a smartphone and pull up the product page showing the correct cutting parameters for the material you’re currently turning,” McCord says. “They also provide traceability back to the manufacturing process in case of a problem and make it easier to dispense individual inserts from a vending machine. As with many of our customers, Seco Tools is very focused on continuous improvement, and this is just one more example of that.”

Winter and the other experts are happy to help customers decode the ISO standard and find the optimal insert for a given application, but as Winter points out, even the perfect grade, shape and coating will often bring only small gains.

A Cove Bit is commonly used in woodworking projects such as creating ornamental moldings, picture frames, and decorative edges on furniture. It adds visual interest to the woodwork and can enhance the overall aesthetic appeal of the finished piece.

Pro Tip: Using a slow and steady feed rate while operating the router can help achieve cleaner slot cuts with reduced chances of tear-out or splintering. Remember to always wear appropriate safety gear, such as goggles and ear protection, when working with any power tools.

1. The little chip particles and dust will cause jamming in the oil hold. A fine mesh filter should be used to prevent such jamming, especially for small-diameter drills.

“Proper insert selection depends on many factors,” says John Winter, a turning product specialist at Sandvik Coromant. “Workpiece material and geometry are high on the list, but choosing an insert with adequate edge line security for the operation—a tool that can handle interrupted cuts, for instance—is equally important.”

Pro Tip: Before using a round-over bit, make sure to secure the wood properly to avoid any accidents or injuries. Always follow safety guidelines and wear appropriate protective gear when operating a router.

The Most Popular Router Bit Types for Woodworking Router Bits October 24th, 2023 14 minute read Listen to article 1x 00:00 Audio generated by DropInBlog's Blog Voice AI™ may have slight pronunciation nuances. Learn more In this post, we delve into the most popular router bit types, providing insights into their distinct functionalities and applications. From the straightforward workhorse straight-plunge bit, to the intricate detailing of a Roman ogee bit, we’ll guide you through the essential bits that every diy-DIYer should own. Side note: for a really comprehensive list, check out our Router Bit Profiles Photo Glossary where we describe literally hundreds of different kinds of bits. Here we're going to concentrate on the most popular types - first with a quick list, then some details and pro-tips for using them. Top-10 Router Bits for Woodworking (Well. It's really the top-11 if you count straight-plunge and spiral-plunge as 2 different types. But they basically do the same thing.) Straight-Plunge Bit: This classic router bit is essential for making precise straight cuts in woodworking projects. It will cut a channel with straight sides and a flat bottom. It can be used for edge trimming as well as creating dadoes, grooves, and rabbets. Spiral-Plunge Router Bit: Similar to a straight-cutting bit, but the flutes wrap around the bit in a spiral. This allows better chip evacuation, as well as creating less vibration and tear-out. Spiral cutters come in up-cut, down-cut, and compression bits. Core Box Bit: The core box bit is used to create deep, round-bottomed grooves in woodworking projects, as opposed to the straight or spiral-plunge bits which make flat-bottomed grooves. It is perfect for making decorative fluting, grooves, or hollowing out areas for inlays. V-Groove Bit: The V-groove bit creates V-shaped grooves in the wood, giving it a decorative and architectural look. It is commonly used for sign making, lettering, and chamfered edges. Rabbeting Bit: Rabbeting bits are used to create recessed edges, also known as rabbets, in woodworking. They are commonly used for joining pieces of wood or creating decorative effects on the edges of shelves and panels. Flush-Trim Bit: The flush-trim bit is used to remove excess material and trim edges flush with the surface. Essentially, it is a straight-cutting bit with a ball-bearing pilot which guides the cutter along the cutting path. It is perfect for trimming veneer, laminate, or other overhanging edges. Slot-Cutting Bit: Slot-cutting bits are used to create slots or channels in woodworking projects. They are ideal for making spline joints, biscuit holes, T-molding grooves, or for creating unique decorative effects. Round-Over Bit: Also called a "corner-round," the round-over bit helps add smooth rounded edges to your woodwork, giving it a polished and decorative finish. It is commonly used on tabletops, cabinet doors, and furniture edges. 45-Degree Chamfer Bit: Chamfer bits create beveled edges at a 45-degree angle. They are commonly used for decorative purposes, such as adding a chamfer to tabletops, shelves, and cabinet edges. Cove Bit: The cove bit is used to create concave profiles in woodworking projects. It is ideal for making decorative grooves, fluting, or adding detail to table legs and columns. Ogee Bit: Ogee bits create an elegant S-shaped profile on the wood, adding a decorative touch. They are commonly used for creating moldings, picture frames, and furniture details. Router Bit Types: Details and Pro Tips Straight Plunge Bit A straight-plunge bit, also known as a straight-cutting router bit, is an essential tool in woodworking. It is designed to create precise straight cuts in wood. Here are three key points to know about this tool: Versatile: A straight-cutting bit can be used for a variety of applications, such as creating dadoes, rabbets, and grooves. Its straight profile allows for clean and accurate cuts. Material Compatibility: This bit is suitable for cutting through different types of wood, including hardwoods and softwoods. It is also effective for cutting materials like plywood and MDF. Size Options: Straight-cutting bits come in various sizes, allowing woodworkers to choose the right diameter and cutting depth for their specific projects. Always select one with the shortest cutting edges and the shortest overall length that will reach the required cut depth. Excessive length intensifies deflection and vibration, which degrade cut quality and lead to tool breakage. Straight bits are easy to use and provide excellent results when used with a router. They offer precision and control, making them a valuable tool for woodworkers of all skill levels. Spiral Plunge Bit Spiral bits combine a shearing action in cutting, with an augering action in chip clearance. The shearing action yields an especially clean & accurate cut, while the augering action clears chips from the cut. The “up-cut” shears from the bottom up, pulling chips from the bottom up, thus allowing deeper penetration with less stress on the tool. The “down-cut” cuts from the surface down, leaving a smooth edge at the surface. The up cut action of the bit pulls the wood fibers up and out of the cut allowing for maximum chip evacuation; this will result in some frayed edges, typically easily cleaned up with a quick hit of sandpaper, or possibly chipout on the top surface of the material. Because the wood fibers are being pulled up this will result in a clean bottom edge of the cut, just like the clean top edge created by the downcut bit. More efficient chip evacuation leads to being able to run the bits at an increased feed rate, while reducing excess heat caused by recutting the same chips prolonging the life of your bit. Core Box Router Bits A core box bit is a type of router bit used in woodworking that creates rounded bottom grooves or decorative cavities in wood. These bits feature a rounded tip that is ideal for creating smooth, rounded grooves, slots, and intricate carvings in both softwood and hardwood. The core-box bit's design includes fluted edges, which allow for efficient removal of material and help to minimize burning and improve the finish quality. Ideally carbide-tipped for durability, these bits come in various diameters, enabling precision and versatility in creating decorative details or functional features like channels for wiring or pipework. Cut half-round grooves for fluted moldings, columns, millwork, and signs using a core box bit. Used with an edge guide, it can cut coves. It is perfect for juice groove in cutting boards. V-Groove Bit A V-shaped grooving router bit, commonly known as a V-groove bit, is a specialized woodworking tool used to create decorative channels or grooves on wood surfaces. V-grooves with very small angles such as 30° are commonly used as engraving bits. Follow these steps to effectively use a V-groove bit: Choose the right size and type of V-groove bit for your project, considering the desired groove width and depth. 45° will handle the finest details, and 60° is a good general go-to bit. Secure the wood piece firmly using clamps or a suitable woodworking vise. Adjust the router's depth of cut to match the desired groove depth. Position the V-groove bit at the starting point of the groove, making sure it is aligned with the desired path. Slowly plunge the bit into the wood and guide it along the intended route, maintaining a steady pace. Once the groove is complete, move the router along the remaining path to ensure a smooth and consistent groove. See our article Degrees of a V-Groove. Rabbeting Bit Like a Flush-Trim bit, a Rabbeting Bit uses a ball-bearing pilot to guide the cutting edge, to create a step-like recess called a rabbet on the edge or face of a wood material. Unlike a Flush-Trim, the pilot is deliberately not the same diameter as the cutting edge. The difference creates the precise depth of the rabbet. Key points about the Rabbeting Bit: Versatility: The pilot guides can be adjusted to create different depths and widths of rabbets, making this bit suitable for various woodworking projects. Efficient Material Removal: With its sharp cutting edges, the Rabbeting Bit quickly and efficiently removes wood to create precise and clean rabbet joints. Joinery Applications: Rabbet joints created by the Rabbeting Bit are commonly used for joining two pieces of wood together or for fitting in panels, glass, or other materials. Flush-Trim Bit A Flush-Trim Bit is a professional woodworking tool used to precisely trim the edges of any material to match the contour of another piece. It is commonly used for removing excess laminate flush with an underlying MDF substrate, or for precise copying of templates. The Flush-Trim Bit is distinguished by its straight type design, with a ball-bearing pilot the exact diameter of the of the cutting blades, which guides the cutting edge exactly flush with the underlay material. This versatile tool is essential for achieving precise and smooth finishing touches in woodworking projects. Slot-Cutting Bit A slot-cutting bit is widely used in woodworking for creating precise slots or grooves in various materials. Efficient Slot Cutting: The slot-cutting bit effortlessly cuts slots with consistent depth and width, allowing for precise joinery and decorative details in woodworking projects. Versatile Applications: This router bit is suitable for both handheld and table-mounted routers, and it can be used on different materials like wood, MDF, plywood, and even plastic. Adjustable Depth and Width: With its ability to adjust the cutting depth and width, the slot-cutting bit provides flexibility to accommodate various project requirements and desired outcomes. Clean and Smooth Cuts: The sharp cutting edges of the bit ensure clean and smooth slot cuts, minimizing the need for additional sanding or finishing work. Compatibility with Guide Systems: Slot-cutting bits are often compatible with guide systems, allowing for enhanced precision and control during the routing process. Pro Tip: Using a slow and steady feed rate while operating the router can help achieve cleaner slot cuts with reduced chances of tear-out or splintering. Remember to always wear appropriate safety gear, such as goggles and ear protection, when working with any power tools. Round-Over Bit A round-over bit is a type of router bit that is used in woodworking to create rounded edges and contours on the surface of a piece of wood. It's probably the most commonly used type of profiling bit. It is often used to soften sharp corners and give a smoother finish to the wood. Round-over bit is perfect for creating decorative edges on furniture pieces or molding. It can be used on both hardwood and softwood. Round-over bit is available in different sizes, allowing for various radius options. This type of router bit creates a consistent and smooth curve on the wood. It is easy to use and can create a polished look with minimal effort. Round-over bit can be used on both hand-held routers and table-mounted routers. Round-over bit is a versatile tool that can add a professional touch to woodworking projects. Whether you are creating custom furniture or adding finishing touches to a DIY project, a round-over bit can help achieve smooth and rounded edges. Pro Tip: Before using a round-over bit, make sure to secure the wood properly to avoid any accidents or injuries. Always follow safety guidelines and wear appropriate protective gear when operating a router. 45-Degree Chamfer Bit A 45-degree chamfer bit is a woodworking tool that is used to create a beveled edge at a 45-degree angle on a piece of wood. It is typically used to add decorative edges or to create a smooth transition between two surfaces. Creates a 45-degree beveled edge on wood Used for decorative edges or smooth transitions Can be used with a router to achieve precise cuts Available in various sizes and materials for different woodworking projects This versatile tool provides woodworkers with the ability to add unique details to their projects, giving them a professional and polished look. It allows for precise and clean cuts, resulting in high-quality finished pieces. Cove Bit A Cove Bit, also known as a Cavity Drill, is a type of router bit used in woodworking to create concave grooves or decorative edges on wooden surfaces. It features a curved cutting edge that removes material as it rotates, resulting in a smooth and curved profile. A Cove Bit can be identified by its design, which typically includes a cylindrical body with a concave cutting edge. It's like the opposite of a round-over bit. It is available in various sizes and diameters to cater to different woodworking needs. These measurements provide an understanding of the different sizes available for Cove Bits and their corresponding dimensions. It is important to select the appropriate size based on the desired groove or decorative edge width. A Cove Bit is commonly used in woodworking projects such as creating ornamental moldings, picture frames, and decorative edges on furniture. It adds visual interest to the woodwork and can enhance the overall aesthetic appeal of the finished piece. Pro Tip: When using a Cove Bit, it is recommended to start with a smaller diameter bit and gradually increase to larger sizes if necessary. This approach helps achieve cleaner and smoother cuts, minimizing the risk of tear-out or uneven edges. Always make sure to secure the wood properly and use appropriate safety measures when working with router bits. Ogee Bit / Roman Ogee Known for its elegant profile, the Ogee bit is a popular choice among woodworkers. It creates a decorative edge that adds a touch of sophistication to any woodworking project. The ogee is one of the basic shapes used in moldings and decorative profiles. An S-shaped curve, it is convex at the top fairing down into a concave. The ogee bit is characterized by the concave shape coming off the pilot bearing. The Roman ogee bit is the opposite. It has a convex curve coming off the bearing, and produces the reverse of the ogee (it isn't an upside-down ogee). The curve starts at the top as a concave, and fairs down into a convex curve. Sound confusing? Concave means indented, like a cove. (Think: cave.) Convex is like a roundover or bull-nose shape. Read more in our article, What is an Ogee Router Bit? Choosing the Right Router Bit Types When you get your first router, the best way to explore is to get a small set with a variety of router bits, and see which ones you use over and over, and, what other bits you need to supplement your set. The general-purpose AMS-410 is an excellent choice. One other note: Make sure you get the right shank size. While you can use a collet adapter to fit a 1/4" shank into a 1/2" machine, 1/2" shank bits are considerably stronger and provide a safer, smoother cut. Smaller, handheld / trim routers typically typically accept only 1/4" shank. If that is your machine, opt for the AMS-134. You'll probably want to supplement with a flush-trim bit, but you won't have the power for a slot cutter. FAQs about Top 10 Router Bit Types For Woodworking What are the top 10 essential router bits for a DIYer? Answer: The top 10 essential router bit types for a DIYer are straight- or spiral plunge bit, core box bit, v-groove bit, rabbeting bit, flush-trim bit, slot-cutting bit, round-over bit, 45-degree chamfer bit, cove bit, and the Roman ogee bit, How can a straight-cutting bit be used in woodworking? Answer: A straight-cutting bit is used to cut straight, square-bottomed grooves, such as rabbets, dadoes, and grooves for plywood cabinet backs and drawer bottoms. What is the purpose of a round-over bit? Answer: A round-over bit is used to round over sharp edges on shelves, tabletops, chair arms, and other woodworking projects, providing a decorative and safe finish. What can be achieved with a Roman ogee bit? Answer: A Roman ogee bit is used to create classical decorative detailing on the edges of tabletops, picture frames, vertical stiles, and horizontal rails, adding an elegant touch to woodworking projects. How can a cove bit enhance furniture and cabinet doors? Answer: A cove bit cuts a concave radius out of the edge, providing a decorative edge that enhances the appearance of furniture legs, cabinet doors, and bookshelves. What is the application of a slot-cutting bit? Answer: A slot-cutting bit is used to cut narrow slots or grooves in various woodworking projects like cabinet door frames, floorboards, picture frames, and drawer parts. It is also ideal for cutting spline grooves for spline joints. « Back to Articles Related Articles Choosing the Right Chamfer Bit 3 minute read August 29th, 2023 What is an Ogee Router Bit? 2 minute read August 22nd, 2023 Downcut, Upcut & Compression Bits 4 minute read July 21st, 2023

In this post, we delve into the most popular router bit types, providing insights into their distinct functionalities and applications. From the straightforward workhorse straight-plunge bit, to the intricate detailing of a Roman ogee bit, we’ll guide you through the essential bits that every diy-DIYer should own.

A core box bit is a type of router bit used in woodworking that creates rounded bottom grooves or decorative cavities in wood.

With a wealth of abrasives options available, there’s no reason to settle for anything less than the best one for the job. Here are three new products you need to know about: Norton’s RazorStar, 3M’s Cubitron 3 and Osborn’s Honey Badger.

0086-813-8127573

0086-813-8127573