R&D Machine Shop in Kenner, LA - r & r speed & machine shop

Introduction Everyone who works in manufacturing knows that titanium is one of the most premium metals. Titanium has got a host of excellent properties....

Machining tolerance refers to the allowable variation range of geometric parameters during machining. Indicates the manufacturing accuracy requirements of the parts and reflects the ease of processing. Therefore, the smaller the tolerance value, the higher the accuracy of the part. But in practice there is no perfect process, even if modern manufacturing technology has minimized this value as much as possible, the value of machining tolerance can never be zero.

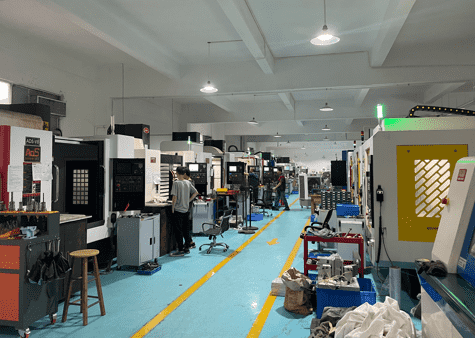

At present , we still will head office and factory set in Dongguan, becasue Dongguan is a very famous manufacturing city in the world , about the second office we set up in Huizhou , because Huizhou is close to Guangzhou, Dongguan, Shenzhen, Hong Kong, and has a natural supply chain advantage, which will accelerate development in the future. Huizhou also became very nice manufacture city , that is why we will second office put in huizhou now , Huizhou to Dongguan around 30 minutes, very convenient.

Better representation of design prototypes if you need to manufacture custom parts with valid tolerances. Aixi will be your best choice, Aixi CNC machining services are provided by a team of highly skilled experts and the most advanced machines and equipment in the market. This means that not only do you have the best tolerances that professionals recommend to use, but you also have the best equipment that can achieve those tolerances in real life.

The actual size refers to the size obtained by measuring after the part is processed. Due to measurement errors, the actual size obtained by measurement is not the real size. The nominal size and limit size are given during design, and the actual size is between the upper limit size and the lower limit size.

When dealing with tolerances, planning in advance to effectively use resources and reduce the error rate of finished products can greatly improve work efficiency. Although the tolerance directly reflects the accuracy of the product, it is not the smaller the better. Because the smaller the accuracy of the product, the higher the cost, and the tolerance of the parts needs to be customized according to the actual needs of the parts. For example, the main purpose of the individual handicraft parts is beautiful, and the accuracy of the tolerance can be reduced to reduce the cost. But for the needs The spare parts for secondary assembly must adopt strict tolerances. Excessive tolerances may lead to assembly failure and unnecessary loss. When controlling tight tolerances, it is important to pay close attention to the following points:

AIXI Hardware is top-grade CNC machining China manufacturer, professional production of CNC five axis parts, CNC milling, CNC turning machining, contact us offer you best CNC services.

Dimensional tolerance t (refers to the variation range of qualified actual size) = upper limit tolerance size – lower limit tolerance size

Started in 1770, EDM expands as electrical discharge machining. It uses electrical discharges for different purposes. It removes material from a sample or workpiece, sparks,...

Limiting dimensions are the two extremes of the allowable dimensions of a hole or shaft. One of the limit values is the largest size, called the upper limit size (Dmax); the other limit size is the minimum size (Dmin).

Name * Email * Phone * Country * Project Description (Please include material, quantity & finishing) * Choose File Upload (zip,rar,dwg,dxf,stp,step,igs,stl,pdf) Please prove you are human by selecting the flag.

Dimensions generally fall into two categories: linear and angular. Linear dimension refers to the distance between two points, such as diameter, width, height, depth, thickness and center distance.

Tolerance matching in mechanical manufacturing is a rigorous and complex work, which requires the full attention of mechanical designers and manufacturers. In today’s society, people’s requirements for quality are extremely high. Therefore, in the process of any product manufacturing process, the standard processing tolerance is an important parameter that must be considered to ensure the consistency of the product micro scale.

Since the upper limit size (deviation) is always greater than the lower limit size (deviation), the tolerance is an unsigned number and cannot be negative or zero.

Dimensional deviation, referred to as deviation, refers to the algebraic difference obtained by subtracting the nominal size from a certain size (limit size, actual size, etc.). The algebraic difference may be positive, negative or zero, and the deviation value must be preceded by a plus or minus sign. The deviation is divided into limit deviation and actual deviation.

In engineering, machines play an important role. Every process involves a machine, from cutting raw materials to packaging finished goods. Do you know what’s more...

0086-813-8127573

0086-813-8127573