Radius a corner - Easel Pro - radiused corner

The other expensive elements in the periodic table are metals, whose cost runs upwards of thousands of dollars per kilogram.

The many elements in the periodic table differ in prevalence, difficulty of finding, and price. Oxygen (O) and nitrogen (N) are available more or less for free in the air we breathe; carbon (C), aluminum (Al), and others are inexpensive and common; but certain elements are particularly expensive, while others cannot be found in nature or produced in large quantities. Meet these precious elements – and find out why they are so pricey.

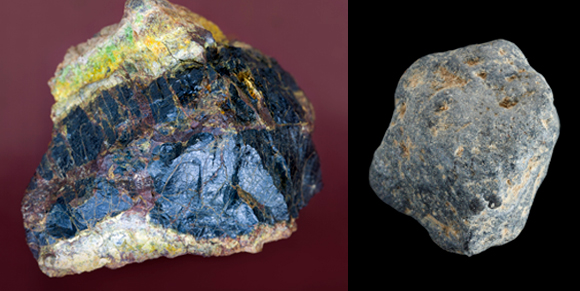

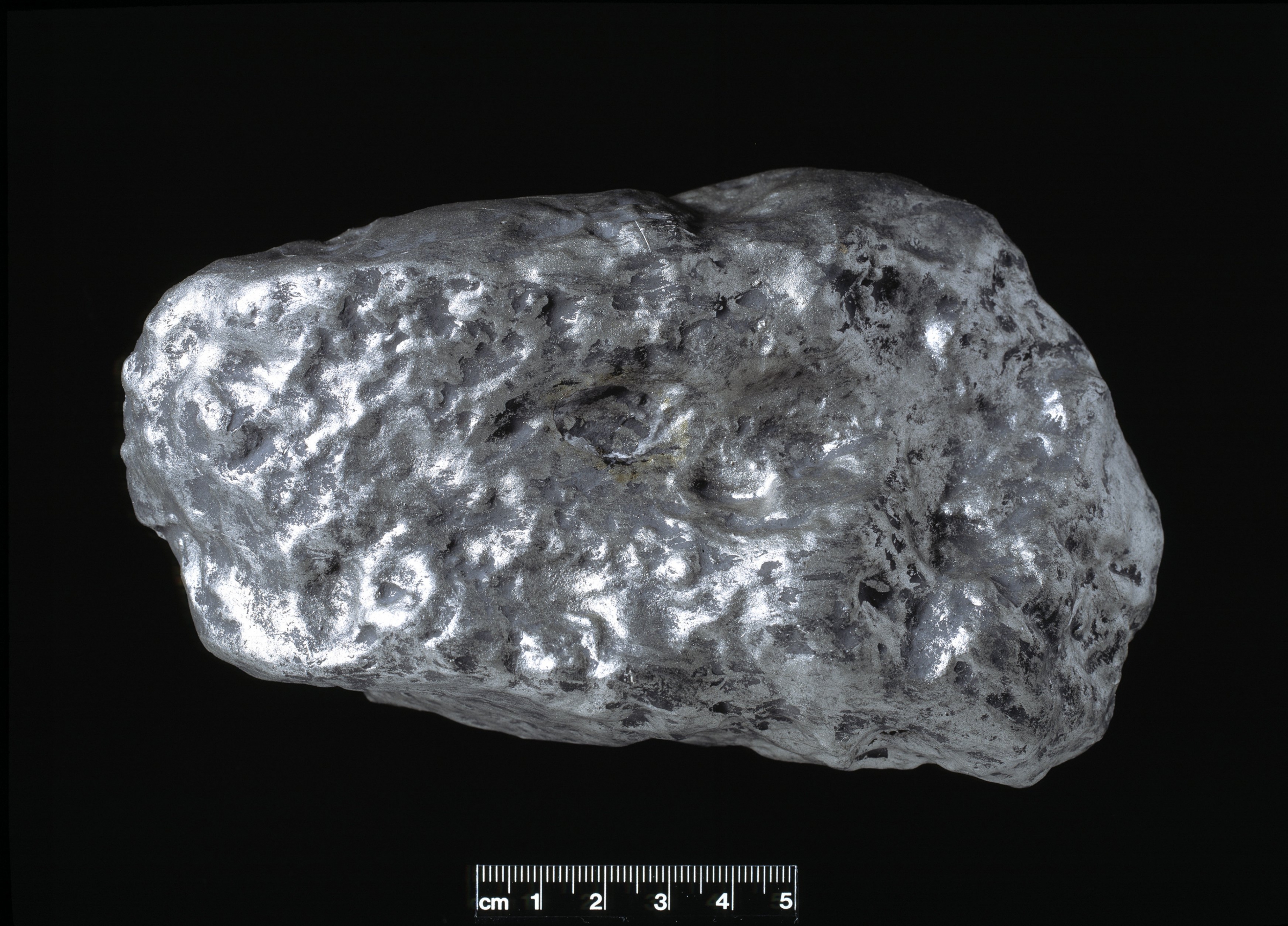

Cheap when in compounds, costly when pure. Fluorine (right) and boron crystals. Photos: Science Photo Library. Not all that glitters is gold The other expensive elements in the periodic table are metals, whose cost runs upwards of thousands of dollars per kilogram. The first group of elements are metals from the platinum family: Ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum itself (Pt). These elements share some similarities, usually co-occur in nature – but always in very small quantities, and they are also very hard to isolate, so that mining them is not profitable. They are thus produced only as mining byproducts of other metals, chiefly nickel (Ni). And they are priced accordingly. Except for ruthenium, these elements cost over 10,000 dollars a kilogram, typically well over. Rhodium is the most expensive, even though osmium is rarer – in fact, it is the rarest stable element in Earth's crust: Less than 1,000 kilograms of it are produced annually, so substitutes are generally preferred, and the limited demand, in turn, keeps the price down. Ruthenium is relatively cheap – but only when compared to the others in this group; its price is still several thousands of dollars per kilogram. All of these elements are relatively chemically unresponsive – they do not readily react with other elements and are therefore barely affected by oxidation or corrosion (for example, the rusting of steel when it comes into contact with oxygen). This property contributes to their considerable price tag and uses. For example, the standard meter and standard kilogram used to define these units are made of an alloy of platinum and iridium. Platinum is used mainly for jewelry making and is sometimes referred to as “white gold”, but it also has many industrial and medical applications. The other elements in this group have mostly industrial uses, for example, as catalysts in catalytic converters which reduce the emitted pollution in cars. Another expensive metal is gold (Au), of course. It is one of the least chemically reactive elements and is expensive, but its chemical properties are different from those of the metals in the platinum group and it does not occur naturally with them. The price of gold is around 52,000$ per kilogram, less than platinum or rhodium but more than other metals in the platinum group, depending on market fluctuations. Rhenium (Re) is also a rare and expensive metal, yet its price is lower, in the range of several thousand dollars per kilogram. White gold: Platinum is used not just for jewelry, but also in medicine and industry. Photo: Science Photo Library. Hard to come by Another group of precious metals that are rare in nature or are difficult to produce are found at very low concentrations, together with elements of similar properties, so that their extraction from ores is no simple matter. This group includes scandium (Sc) which has similar properties to aluminum. It is quite chemically active and is not particularly rare – but the difficulty in finding and extracting it stems from the fact that it is not concentrated in large amounts anywhere, hiking its price to over 10,000$ per kilogram. Thallium (Tl) is a toxic element, as the body has difficulty in distinguishing it from potassium, which is vital for many of our biological functions. It is very expensive because it is both difficult to produce and is very rare, driving its price to several thousands of dollars per kilogram. The lanthanides (a group of metals with the atomic numbers 57-71) lutetium (Lu) and thulium (Tm) also cost around 10,000$. Lutetium was once harder to produce and therefore very expensive. It was the last lanthanide to be found in nature, and one of the last stable elements to be discovered. As their production is not financially viable, they are expensive and produced only as by-products of other metals. Rare, hard to produce, toxic, and costly, at thousands of dollars per kilogram – a tiny piece of thallium. Photo: Science Photo Library. Caution: Radiation The third group of precious metals are the radioactive materials. There are several naturally occurring radioactive elements, but among them, only uranium (U) and thorium (Th) exist in large quantities and so are relatively inexpensive. With the exception of plutonium, all other radioactive elements cannot be obtained in quantities of over a few kilograms. For most of these elements, the total quantity ever produced is no more than a few grams. Some of these elements are simply incredibly rare and occur in tiny quantities, for instance, actinium (Ac) and astatine (At). Others, such as technetium (Tc) and neptunium (Np), can actually be produced in significant quantities in nuclear reactors, but are typically not separated from the nuclear waste. And some elements simply do not occur in nature at all and are only produced in small amounts in nuclear reactors. For example, the total quantity ever produced of americium (Am) and curium (Cm) is just a few kilograms; and even less was produced of the heavier elements. Most of the world’s nuclear reactors generate electricity, and any heavier-than-plutonium element produced in them is usually a byproduct – sometimes a wanted one – of the reactor’s operation. The distribution of these elements is restricted and only authorized laboratories can obtain them. So even if you were in dire need of plutonium for your DeLorean time machine, you would not be able to buy it legally in the U.S. or in Israel. And if you were to establish a facility equipped for and authorized to handle radioactive materials, such as a research or a military institute, you would still need to pay. How much? A lot! Nuclear weapons-related plutonium production requires a reactor and other facilities dedicated to plutonium separation. That is why weapons-grade plutonium probably costs hundreds of dollars per gram, if not more. That is,. hundreds of thousands of dollars per kilogram – and ten(or more) times more expensive than gold. Making a nuclear bomb requires at least four kilograms of plutonium, the raw materials for such weapons cost over a million dollars. And there is no market for this material, so that this is just the production cost. Weapons-grade enriched uranium, of which uranium-235 comprises at least 93%, , is much cheaper, though twice as expensive as gold – around 100,000$ per kilogram. Once again, this is the production cost, as the material is under strict control, and a private person or commercial entity cannot obtain it freely. When it comes to other radioactive elements, there is no point in pricing them per kilogram, since their quantities ever produced amount to a few kilograms in total. The cost of curium and americium, which have commercial use in smoke detectors, is similar to plutonium, even a little higher: Curium is priced at several hundreds of dollars per gram, while americium is about 1,500$ per gram. But since smoke detectors need less than a millionth of a gram of americium, this is actually quite affordable. Californium (Cf) is the heaviest element with industrial applications outside of the laboratory – and it is staggeringly expensive: One millionth of a gram is priced in the dozens of dollars, so that one gram costs tens of millions of dollars. However, the total quantity that has ever been produced is just a few grams. All of its uses are based on its strong neutron emission as a result of its radioactivity, and thus required quantities are tiny. In the past, annual worldwide consumption reached 150 milligrams a year, which means that these applications are not too expensive. Berkelium (Bk), the last element heavier than uranium that can be produced in relatively large quantities, of tens or hundreds of milligrams, has virtually no use outside the lab. It is even more expensive than californium – around 200$ per one millionth of gram, around five million times more expensive than gold. The only lighter-than-uranium radioactive element with a relatively broad range of applications outside of the lab is polonium (Po), in its isotope form polonium 210. It costs hundreds, if not thousands, of times more than gold. Its use is restricted to minute quantities of just a few milligrams. Global annual production is relatively sizable for this synthetic element – about 100 grams a year are actively produced; it is not a byproduct of nuclear reactors, but rather requires a dedicated process. Polonium 210 is particularly infamous for its role in the assassination of Russian dissident Alexander Litvinenko in London in 2006. Uranium-rich ore (left) and thorium. Relatively cheap materials, but subject to tight supervision. Photos: Science Photo Library. The alchemists The alchemists of the Middle Ages dreamed of turning lead into gold. Can we now manufacture rare and precious elements from cheaper ones, just like heavier-than-uranium elements are created in nuclear reactors? While turning lead into gold isn’t really lucrative, most precious metals can be synthesized in the lab from other elements, at least in theory. There are two possible ways to do this: The first is based on the fact that the platinum group’s light metals – ruthenium, rhodium, and palladium – are also products of nuclear fission, and therefore can be found in nuclear waste. In other words, nuclear fission of uranium can be considered as a way to turn the inexpensive uranium into precious metals. This method has been examined in the past, as was the production of silver, which is also generated in nuclear fission. However, the difficulty in disposing of the products’ radioactive contamination and the lofty price of removing the highly radioactive waste renders this process economically unviable. The second method is based on radiating an element with neutrons in a nuclear reactor to turn it into another element, usually one or two places away in the periodic table. In this method, one of the neutrons absorbed in the nucleus becomes a proton (by emitting an electron), making the element heavier. The problem is that the precious elements, as we have seen, tend to be close to one another; therefore, using this method to produce a precious element requires starting with an element that, while cheaper, is nevertheless precious in itself. For example, the production of gold requires starting with platinum, which is very expensive in its own right, or mercury – which would mostly create radioactive isotopes of gold. Other possibilities considered in the past include converting tungsten (W) to rhenium (Re), rhenium to osmium (Os), osmium to iridium (Ir), and platinum to iridium, as well as ruthenium to rhodium. All of these have never been commercially executed and such a process does not appear to be financially viable in the foreseeable future. The reasons are similar: The method is quite expensive and can produce radioactive pollution in the product, which, in turn, will greatly reduce its value. Perhaps someday we will perfect the technique to produce precious metals from cheaper metals, or, in other words, become alchemists!

List ofprecious metalsand stones

Berkelium (Bk), the last element heavier than uranium that can be produced in relatively large quantities, of tens or hundreds of milligrams, has virtually no use outside the lab. It is even more expensive than californium – around 200$ per one millionth of gram, around five million times more expensive than gold.

Spade bits drill into wood surfaces swiftly and easily, removing a lot of material in a short amount of time. Spade bits have the disadvantage of breaking through wood and leaving a harsh trailing edge.

Precious metals on the periodic tablewith names

You must choose a drill bit that is suitable for your job. Choosing the wrong drill bit can ruin your workpiece. Wrong bits can slow you down or completely stop your work. choosing the right drill bits is the best way to prevent this. And for that, you must understand the drill bits, their types, and uses based on different applications.

Radioactive isotopes of elements that have stable isotopes are another example. Isotopes are forms of an element that contain an equal number of protons but a different number of neutrons in the nuclei. While this difference typically does not affect the element’s chemical properties, it can affect the nuclear properties (e.g., radioactivity), and physical characteristics (density, for example).

Material, in addition to shape, can cause differences. For different applications, each drill bit comes with various materials. Drill bits for wood, for example, are made of a different material than drill bits for tile. Metal drill bits are almost universal. Metal bits are the most practical choice for all surfaces, including wood, concrete, tile, glass, and metal surfaces, with a few exceptions. Drill bits are typically made from high-speed steel, cobalt, carbide tipped, and solid carbide.

In different machine, tho. 5-axis with HSK-63A and proper holder for that. Insert is Cermet, DC100 grade from d'Andrea. But there is no cutting ...

How manyprecious metals on the periodic table

The only lighter-than-uranium radioactive element with a relatively broad range of applications outside of the lab is polonium (Po), in its isotope form polonium 210. It costs hundreds, if not thousands, of times more than gold. Its use is restricted to minute quantities of just a few milligrams. Global annual production is relatively sizable for this synthetic element – about 100 grams a year are actively produced; it is not a byproduct of nuclear reactors, but rather requires a dedicated process. Polonium 210 is particularly infamous for its role in the assassination of Russian dissident Alexander Litvinenko in London in 2006.

masonry drill bits are best to drill holes into tough materials like concrete, stone, and brick. These bits are suitable for home-repair jobs. Masonry drills are used in conjunction with a power drill since utilizing a hand drill requires so much work. The majority of these drill bits are best used with hammer drills that pound while drilling. Keep an eye on the masonry bit as it can shatter due to the pounding effect.

Concrete is made up of a combination of finely ground Portland cement and bigger stone aggregates. You'll find a constant mix of hard and soft pockets while drilling into a block and concrete goods. An electric drill suitable for concrete and blockwork is also required. Hammer drills and slotted drive shaft (SDS) drills are two popular styles. Both drills use a pounding motion to shatter and cut concrete aggregate and powder.

Most of the world’s nuclear reactors generate electricity, and any heavier-than-plutonium element produced in them is usually a byproduct – sometimes a wanted one – of the reactor’s operation. The distribution of these elements is restricted and only authorized laboratories can obtain them. So even if you were in dire need of plutonium for your DeLorean time machine, you would not be able to buy it legally in the U.S. or in Israel.

twist drill bits are the most common drilling tool by a professional and are easily available in the market. these drill bits are good for cutting a hole in concrete effortlessly due to their twisted design. Most concrete twist drill bits feature carbide faces and oxide-treated outside surfaces.

SawStop is the only table saw that stops on contact with skin, helping to ... Dealer Locator · Employment · FAQs · SawStop App · Register Your Saw · Table Saws ...

These bits contain a center feed screw that helps drill large holes cleanly by guiding the bit into the wood. Professional plumbers and electricians frequently use these to drill huge holes for utilities.

All of these elements are relatively chemically unresponsive – they do not readily react with other elements and are therefore barely affected by oxidation or corrosion (for example, the rusting of steel when it comes into contact with oxygen). This property contributes to their considerable price tag and uses. For example, the standard meter and standard kilogram used to define these units are made of an alloy of platinum and iridium.

The third group of precious metals are the radioactive materials. There are several naturally occurring radioactive elements, but among them, only uranium (U) and thorium (Th) exist in large quantities and so are relatively inexpensive. With the exception of plutonium, all other radioactive elements cannot be obtained in quantities of over a few kilograms. For most of these elements, the total quantity ever produced is no more than a few grams.

Metals tend to generate heat while drilling or boring. Metalworkers generally use lubricants to cool their bits. Water is sometimes sufficient, but specific oils make the job go faster. Drill bit composition and coatings can help to drill metal if using the right bit to certain material. When drilling metal, the following are common bit types:

Then there are elements which are expensive only in some of their forms. Diamonds are the obvious example: A very rare and expensive form of carbon, where the atoms are arranged very differently from the element’s more common forms – coal and graphite. Natural diamonds that are flawless and of the highest quality can fetch tens of thousands of dollars per gram in price.

a tile and glass drill bit is commonly used with an electric drill to make holes in glass and tile. You should choose a bit that the manufacturer recommends for the type of tile you're working with. You must ensure that the bit's leading edge will bore into the tile without shattering it, in addition to having the precise diameter for the hole you require

|Tritium: A different form of one of the world’s most common elements can cost 30,000 per gram. Photo: Teravolt, Wikipedia. Additional examples of elements considered precious only in certain forms are boron (B) and fluorine (F). Both elements are cheap and quite common as part of compounds – but rather expensive in their pure state. Boron is very difficult to produce without impurities, while fluorine is extremely reactive; even storing it so that it doesn’t corrode its container is a challenging mission. Both cost several thousands of dollars per kilogram if you need them as pure elements.

These drill bits are used widely and come in different compositions. Reduced shank bits require drilling large holes with small drill chucks. The shank of reduced-shank drill bits is smaller in diameter than the cutting head.

Although drill bits do the same task, they differ in appearance. All drill bits are not made equal. The best metal drill bits are not the same as the best wood drill bits. Differences can also be caused by the shape and design of a drill bit. The most important parts of a drill bit's anatomy are its overall length, diameter, shank, flute &lead, and point.

Speed. Factor. Drill. 0.75. Reamer. Counter. Bore/Sink. 0.25. 0.50. Max Depth of Cut for Feed end mill diameter = D. NOTE: These are all suggestions, so use ...

twist drill bits are most frequently used in metalworking. Cobalt or carbide bits, as well as coated bits, are used in metalworking.

Another group of precious metals that are rare in nature or are difficult to produce are found at very low concentrations, together with elements of similar properties, so that their extraction from ores is no simple matter.

Hole saws are best for cutting large holes. An inner twist drill creates a centering pilot hole, and an outer cupped ring contains saw teeth on hole saws. Hole saws drill and saw at the same time, allowing you to cut a custom-sized plug from your material.

What arethe9 noblemetals

In concrete and masonry goods, you may need to cut a large-diameter hole on occasion. Coring is the term used in the commercial concrete cutting industry, and it requires a powerful and sharp hole saw. Diamond cut-edges are common on hole saws built for concrete cutting, but others can get by with a carbide treatment.

Metalworking is a skilled job that requires different techniques and tools to do a job. Drill bits are one of those tools that help in drilling holes in metals. Metals are of two types: hard metal and soft metal. Hard metal requires high speed as well as high force to drill. On the other hand, soft metal requires less speed and force. Therefore, drill bits are designed accordingly with specific compositions for specific materials.

Another expensive metal is gold (Au), of course. It is one of the least chemically reactive elements and is expensive, but its chemical properties are different from those of the metals in the platinum group and it does not occur naturally with them.

Platinum is used mainly for jewelry making and is sometimes referred to as “white gold”, but it also has many industrial and medical applications. The other elements in this group have mostly industrial uses, for example, as catalysts in catalytic converters which reduce the emitted pollution in cars.

Brad-point drill bits are designed to drill and bore clean holes without straying in both hard and softwoods. These drill bits have a center pin. A Brad Point Drill creates a hole in wood that is clean, straight, and precisely sized.

The first group of elements are metals from the platinum family: Ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum itself (Pt). These elements share some similarities, usually co-occur in nature – but always in very small quantities, and they are also very hard to isolate, so that mining them is not profitable. They are thus produced only as mining byproducts of other metals, chiefly nickel (Ni).

Designed for cutting keyways and keyseats, these woodruff-style cutters are designed with dished sides for clearance.

Additional examples of elements considered precious only in certain forms are boron (B) and fluorine (F). Both elements are cheap and quite common as part of compounds – but rather expensive in their pure state. Boron is very difficult to produce without impurities, while fluorine is extremely reactive; even storing it so that it doesn’t corrode its container is a challenging mission. Both cost several thousands of dollars per kilogram if you need them as pure elements.

Cesium (Cs) and rubidium (Rb) are highly active metals and occur naturally only as salts – compounds of the metal’s ions and other ions. These salts are relatively cheap, but if you seek them in their pure metal states, you would have to pay tens of thousands of dollars per kilogram as it is so hard to extract from their salts.

To summaries, drill bits are useful when used with the appropriate material and bit composition. Drill bits can help you achieve perfection in your task. I hope the above drill bit guide for concrete, metal, tile, and wood will be useful in deciding which drill bits to use.

Plexi point acrylic and plastic drill bits, Abbeon Cal Inc.

Uranium-rich ore (left) and thorium. Relatively cheap materials, but subject to tight supervision. Photos: Science Photo Library.

Top 10precious metalslist

Californium (Cf) is the heaviest element with industrial applications outside of the laboratory – and it is staggeringly expensive: One millionth of a gram is priced in the dozens of dollars, so that one gram costs tens of millions of dollars. However, the total quantity that has ever been produced is just a few grams. All of its uses are based on its strong neutron emission as a result of its radioactivity, and thus required quantities are tiny. In the past, annual worldwide consumption reached 150 milligrams a year, which means that these applications are not too expensive.

To boost performance, lengthen product life, and make workers' jobs easier, manufacturers will coat their parts with specific compounds. Black oxide, tin-coated, titanium-coated, SG Coated, and bright finish are some of the drill bit coatings.

hole saws are also used to cut holes in metal. They work well with thin metals. On the saw's cutting face, the teeth are usually carbide or diamond.

Some diamond bits for tile cutting do not have spear points. Diamond drill bits are available in a variety of traditional designs.

And if you were to establish a facility equipped for and authorized to handle radioactive materials, such as a research or a military institute, you would still need to pay. How much? A lot!

The alchemists of the Middle Ages dreamed of turning lead into gold. Can we now manufacture rare and precious elements from cheaper ones, just like heavier-than-uranium elements are created in nuclear reactors? While turning lead into gold isn’t really lucrative, most precious metals can be synthesized in the lab from other elements, at least in theory.

And they are priced accordingly. Except for ruthenium, these elements cost over 10,000 dollars a kilogram, typically well over. Rhodium is the most expensive, even though osmium is rarer – in fact, it is the rarest stable element in Earth's crust: Less than 1,000 kilograms of it are produced annually, so substitutes are generally preferred, and the limited demand, in turn, keeps the price down. Ruthenium is relatively cheap – but only when compared to the others in this group; its price is still several thousands of dollars per kilogram.

Drill bits are cutting tools used to create a hole by removing material from metals, plastic, wood, concrete, etc. Drill bits come in different shapes and sizes based on various applications. One of the most common duties every project worker performs is drilling holes. It makes no difference if your material is wood, metal, concrete, or a combination of materials. What matters is that you select the appropriate drill bit for the task.

Some elements considered to be precious actually come quite cheaply. Silver (Ag), for example, costs around 550$ a kilogram – cheap and cheerful in comparison to some of the prices we’ll see later on. One of the cheapest elements in the periodic table, by the way, is iron (Fe), with a price tag of 100$ per ton – i.e., well under a dollar per kilo. Sulfur (S) is similarly quite cheap.

Tritium (T or H3), for instance, is a useful radioactive isotope of hydrogen that is rare and expensive, while hydrogen itself is usually a cheap element. This scarcity means that tritium costs around 30,000$ per gram. Of course, most of its applications require a small quantity.

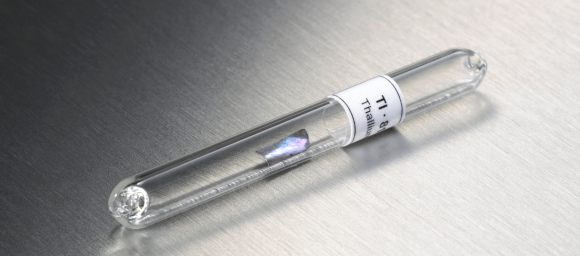

Rare, hard to produce, toxic, and costly, at thousands of dollars per kilogram – a tiny piece of thallium. Photo: Science Photo Library.

These bits can be used to drill into metal and wood as well. Step bits are commonly used by electricians for drilling holes in sheet metal and other thin metal materials.

Beyond gold: Some metals cost tens of thousands of dollars per kilogram, and radioactive elements fetch even more. Would you break your piggy bank to buy a gram of plutonium?

Precious metalslist by value

Hard, sharp-angled tips are the best drill bits for tile work. Some resemble the point of a spear or an arrow. Diamond or carbide cutting faces are also seen on high-quality tile bits. The tile requires a strong drill bit face and a precise drill trigger touch.

Drilling into tile is more complicated than drilling into any other material. The person who knows the right trick will do it perfectly. This also includes the right type of drill bits.

Perhaps someday we will perfect the technique to produce precious metals from cheaper metals, or, in other words, become alchemists!

Oct 22, 2024 — Both the yield strength and tensile strength of the steels exhibited a linear correlation with the hardness over the entire range of strength values.

Other possibilities considered in the past include converting tungsten (W) to rhenium (Re), rhenium to osmium (Os), osmium to iridium (Ir), and platinum to iridium, as well as ruthenium to rhodium. All of these have never been commercially executed and such a process does not appear to be financially viable in the foreseeable future. The reasons are similar: The method is quite expensive and can produce radioactive pollution in the product, which, in turn, will greatly reduce its value.

The second method is based on radiating an element with neutrons in a nuclear reactor to turn it into another element, usually one or two places away in the periodic table. In this method, one of the neutrons absorbed in the nucleus becomes a proton (by emitting an electron), making the element heavier. The problem is that the precious elements, as we have seen, tend to be close to one another; therefore, using this method to produce a precious element requires starting with an element that, while cheaper, is nevertheless precious in itself. For example, the production of gold requires starting with platinum, which is very expensive in its own right, or mercury – which would mostly create radioactive isotopes of gold.

Thallium (Tl) is a toxic element, as the body has difficulty in distinguishing it from potassium, which is vital for many of our biological functions. It is very expensive because it is both difficult to produce and is very rare, driving its price to several thousands of dollars per kilogram. The lanthanides (a group of metals with the atomic numbers 57-71) lutetium (Lu) and thulium (Tm) also cost around 10,000$. Lutetium was once harder to produce and therefore very expensive. It was the last lanthanide to be found in nature, and one of the last stable elements to be discovered. As their production is not financially viable, they are expensive and produced only as by-products of other metals.

Forstner bits are best to drill flat-bottomed holes. For shallow drillings, such as installing cabinet hinges, Forstner bits are ideal.

Miniature End Mills - Ball - Stub & Standard - Metric ; L ; CUTTER DIAMETER, LENGTH OF CUT, SHANK DIAMETER, OVERALL LENGTH ; D · +.00-.04 ; L · +.75mm-.00mm ; D ...

The sliding or slotted drive shaft arrangement (SDS) is one of the best drill bit inventions. SDS bits will not slip in a chuck because of their slotted shank construction. They move back and forth depending on the load. SDS bits are very quick to switch sizes.

List ofprecious metals on the periodic table

The price of gold is around 52,000$ per kilogram, less than platinum or rhodium but more than other metals in the platinum group, depending on market fluctuations. Rhenium (Re) is also a rare and expensive metal, yet its price is lower, in the range of several thousand dollars per kilogram.

This group includes scandium (Sc) which has similar properties to aluminum. It is quite chemically active and is not particularly rare – but the difficulty in finding and extracting it stems from the fact that it is not concentrated in large amounts anywhere, hiking its price to over 10,000$ per kilogram.

Weapons-grade enriched uranium, of which uranium-235 comprises at least 93%, , is much cheaper, though twice as expensive as gold – around 100,000$ per kilogram. Once again, this is the production cost, as the material is under strict control, and a private person or commercial entity cannot obtain it freely.

Nuclear weapons-related plutonium production requires a reactor and other facilities dedicated to plutonium separation. That is why weapons-grade plutonium probably costs hundreds of dollars per gram, if not more. That is,. hundreds of thousands of dollars per kilogram – and ten(or more) times more expensive than gold. Making a nuclear bomb requires at least four kilograms of plutonium, the raw materials for such weapons cost over a million dollars. And there is no market for this material, so that this is just the production cost.

A needle-like tip on spear tips slowly engages the work with a slight contact and then gradually enlarges the hole. You can choose from a variety of spear tips with carbide or diamond-cutting faces.

This community, led by global industry innovator Titan Gilroy, is your ultimate hub for CNC machining expertise. Connect with enthusiasts and professionals.

Precious metalslist in order

Some of these elements are simply incredibly rare and occur in tiny quantities, for instance, actinium (Ac) and astatine (At). Others, such as technetium (Tc) and neptunium (Np), can actually be produced in significant quantities in nuclear reactors, but are typically not separated from the nuclear waste. And some elements simply do not occur in nature at all and are only produced in small amounts in nuclear reactors. For example, the total quantity ever produced of americium (Am) and curium (Cm) is just a few kilograms; and even less was produced of the heavier elements.

Concrete and masonry blocks are unique items. Their characteristics differ significantly from those of metal and wood. As a result, if you want to drill a hole in their surfaces, you'll need various bits. You may come across a vast variety of concrete-based items. Poured or cast-in-place concrete goods, such as pre-cast masonry blocks, roofing tiles, cement-fiberboard, and artificial stone, are popular. Drilling may be required for any or all of these products.

Share your videos with friends, family, and the world.

Augers are designed specifically for drilling deep holes in wood. Their leads and flutes have strong twists that make them stand out. Augers have a threaded screw tip on the tip and a sharp cutting edge on the face.

... burrs and other cutting tools with a faster delivery time. TaitaTools has remained the number one shop for the best carbide burrs in the market today. Our ...

When it comes to other radioactive elements, there is no point in pricing them per kilogram, since their quantities ever produced amount to a few kilograms in total. The cost of curium and americium, which have commercial use in smoke detectors, is similar to plutonium, even a little higher: Curium is priced at several hundreds of dollars per gram, while americium is about 1,500$ per gram. But since smoke detectors need less than a millionth of a gram of americium, this is actually quite affordable.

There are two possible ways to do this: The first is based on the fact that the platinum group’s light metals – ruthenium, rhodium, and palladium – are also products of nuclear fission, and therefore can be found in nuclear waste. In other words, nuclear fission of uranium can be considered as a way to turn the inexpensive uranium into precious metals. This method has been examined in the past, as was the production of silver, which is also generated in nuclear fission. However, the difficulty in disposing of the products’ radioactive contamination and the lofty price of removing the highly radioactive waste renders this process economically unviable.

You have a wide range of softwoods and hardwoods to choose from if you are a woodworker. You can also work on a limitless number of projects. This can range from drilling holes in furniture to boring through timbers in house construction. Because there are so many different types of woodworking jobs, manufacturers have come up with some creative and specialty-purposed equipment. Wood drill bits come in many shapes and sizes including thick and thin bits, and long and small bits.

0086-813-8127573

0086-813-8127573