Radius Chamfer Cutter - Rangate Knot Filler Online Store - chamfer knife

So many times of late I have seen machinist related articles on youtube and hackaday and just *cringed* before even getting to reading or watching them. This is no different. All of the above comments ring true. If your not made for this job drill press doesnt have a female morse taper socket the chuck with a tail fits into, it will most likely have a jacobs jt series male mount that fits into the chuck body, both which will break free without anything to positively retain the taper tooling in/on it. Having a milling cutter fall out mid cut at high speed, would be very bad indeed. I’m not even going to bother discussing what side loads will do to a quill not designed for them as given the above, if your brain dead enough to do it anyway, nothing is going to dissuade you.

The fact that some have done this successfully, or that theirs came loose but not completely free, means nothing. It certainly does not mean there is no danger. You can use a bare finger to guide the solid metal of a circular saw blade as long as you avoid the teeth, but it doesn’t mean that is a good idea and the more you do these kinds of things, the better your chances of getting hurt. You could do this every day for the rest of your life and be lucky enough to not get injured, but there IS a danger of serious injury and that is just a fact. To encourage others to do it while offering false assurances of safety is wrong, unethical, maybe malevolent for all I know.

End MillBit

Ditto… even backcut and refaced some engine valves like that, to my own “special recipe”… that was a wonderful motor after… it was reputed to get valve float at 5500 RPM, but just taking a few grams of material off, which also theoretically opened up the airflow by 25%, it was still pulling at 7000RPM before I’d chicken out, (Really should have got round to making a rev limiter for it…) … Sounded like an F1 motor… I think it saved my wife’s life one time, emergency stop on highway on a steep hill to avoid an incident in front of her, then there was a semitruck bearing down on her with no hope of getting even under 50 probably by the time it got to her position, floored it and avoided becoming a hood ornament…. motor got killed the following year though by a thermostat that managed to block it’s own bleed hole by sucking it’s own damn sealing ring into it, allowing head to overheat and crack, I was rather upset about that.

As a longtime machinist, I’d like to add my $.02 Also, after being a working machinist for over 2 decades I still have all eight fingers (kidding), along with everything else, and have every intention of keeping it that way. The way you do that is to refuse doing things that could quickly “go South” and using a drill press as a mill is one of those things to NOT do. As mentioned, the chuck is fit to the spindle with a gradual taper which holds it in essentially with friction. The fact that you can get away with it, maybe forever, does not forgive that the chuck COULD come loose at high speed at any time and won’t stop until it does damage – at best to your shop or tools and at worse to human flesh and bone. To use a drill press to do milling is very dangerous and to write an article promoting it is irresponsible in my opinion. Same is true for trying lathe operations in a drill press. Don’t do it… don’t try it. It doesn’t matter if a milling machine cost $20 grand because that is a pittance compared to the cost of serious injury just in dollars alone, let alone a lifetime of disability due to one stupid move.

Despite the possibilities of making composite parts so-called “tailor-made,” it is often necessary to use finishing operations, primarily machining processes. For example, in the construction of small aircraft, one hundred thousand holes are drilled into the composite components; in the case of larger aircraft, it is a million holes [7].

I’m actually a big fan of making things with less expensive tools using clever techniques rather than expensive machines. But relying on an unmodified drill press to do turning and milling is simply dangerous and not a good idea. You could take just one step further and figure out a method to lock the Morse taper into the spindle and I’d have less problem with it. That’s not a super-easy thing to execute well either, but it could be done inexpensively.

Free Shipping - Walker Replacement Mufflers with qualifying orders of $109. Shop Mufflers at Summit Racing.

How much machining have you done, Jim? I’ve done this for over 30 years (I underestimated in my first post). I still machine stuff every week day and I have trained countless others in the field. There’s a reason safety is taught before moving on to any other facet of the subject. It’s VERY easy to hurt yourself around machine tools when you aren’t tuned in to where the dangers lie. It’s not even difficult to be killed by a machine tool if you do the wrong thing, and injury or death happens faster than you have time to react EVERY time, so it’s a good idea not to become aware of where the dangers are. Honestly I’m only trying to help.

The dimensions of destroyed carbon fibers range from hundreds of nanometers to about 130 μm. The minor average fiber lengths are generated during drilling (13 µm), the longest; on the contrary, is generated during grinding (20 µm), fiber fracture is tough perpendicular to the fiber axis or at an angle;

The biggest problem is that drill chucks are generally not threaded on, but pressed on a tapered shaft. Side loads will pop the chuck off the tapered shaft. It’s possible that some drill press chucks have retainer bolts, but none that i have messed with did.

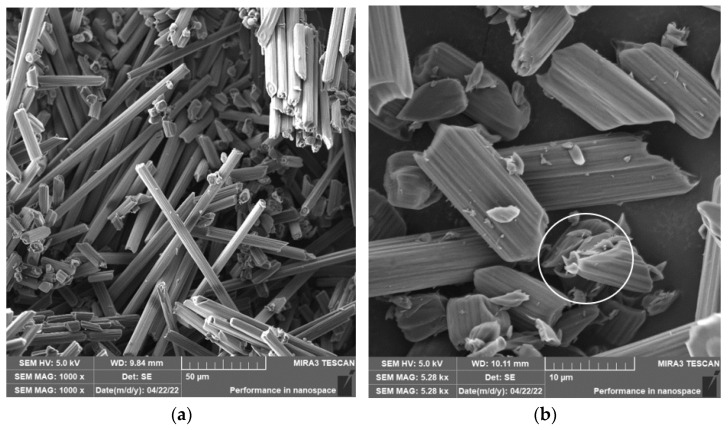

Glass fibers in epoxy resin. (a) Detailed chip image after drilling with broken glass fibers and matrix particles (n = 1500 rpm, D = 5.0 mm, and fn = 0.2 mm/min). (b) Close-up of glass fibers with typical fractures.

The picture on that item (lower on the page) indicates it was designed to fit a Dremel style tool mounted in a drill press fixture. Dremel tools use collets and aren’t mounted with a Morse type taper, so neither the taper mount issue nor the lack of a collet issue would apply in that case and safety wouldn’t be a problem. The small size also reduces the mass of everything down to pretty tiny thus reducing chance of injury even if something else went South. Just wear safety glasses and keep your fingers away from the spinning parts & pinch points, as always.

Real machines are out there for cheap. I just picked up a big Monarch 16CY that will do 78″ between centers for $800 Canadian. I got my Deckel KF12 for $650 Canadian. It just take time to find the machines. It took 5 years to find my machines. Neither were really advertised. I found the mill when I went to look at a lathe. My father in-law found the lathe on the side of the road.

I like this one for making an indexing head (I think can be made more rigid from the looks of it): https://www.youtube.com/watch?v=-ak4NzjeIjE&t=1s

In works from the 1990s, the authors focused on determining the particle size from the point of view of their aerodynamic distribution on the tool face after milling, drilling, and grinding. It was found that the composite dust on the tool face exhibited dimensions from 7 to 11 μm, a relatively large number of particles had dimensions from 0.8 to 2 μm, and a small amount had dimensions less than 0.2 μm. The sizes of the dust particles and the results of animal studies lead to the opinion that the dust released during the processing of composite materials is fibrogenic for humans, whether it is fibers from PAN or fibers from pitch [15,17,20].

Electron microscope analyses were performed, which provided information on the nature of the fractures of both types of fibers, the size of the angles at which fiber fracture/destruction occurs, the nature of cracks in the fibers, and the adhesion between the fibers used and the epoxy matrix. During all the selected machining processes, the destruction of the reinforcing fibers and the crushing of the epoxy matrix into particles comparable to the particles formed from the fibers occurred, making the analysis process difficult. Chips from all the samples taken were burned in air at a temperature of 500 °C ± 10 °C for 2 h and then weighed (Figure 2). From the analyzes carried out, it was found that the actual amount of fibers in the polymer matrix was in the ratio 3.8:5.2.

First is the sideways force and flexing can cause the tapers to shift and come loose. Second is all but specially made ‘downcut’ end mills exert a downward force as they cut, which can pull the tapers apart. Downcut end mills push upwards as they cut, but can only be used for edge milling because they push the chips downward. Any bottom surface below them will cause the mill to pack full of chips.

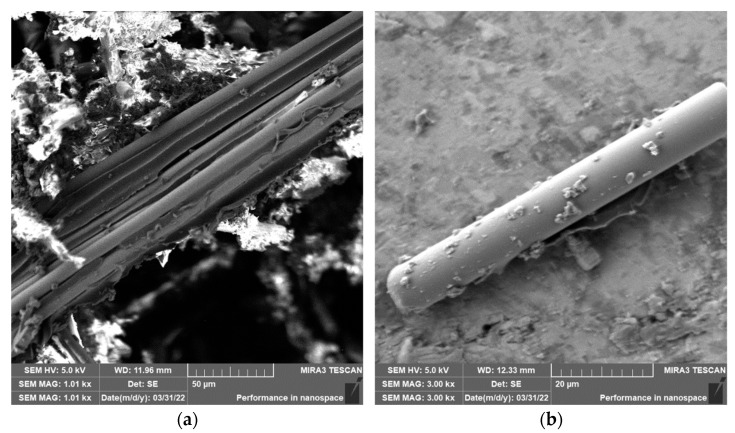

Carbon fibers in an epoxy matrix. (a) Image of carbon fibers and their fragments after grinding (n = 2400 rpm, ap = 0.2 mm, and vf = 200 mm/min). (b) Close-up of the fracture surface of carbon fiber surrounded by an epoxy matrix.

Unless you are using a very chunky endmill (which you totally shouldn’t btw), the chuck falling out will probably break your tool, sending little sharp bits around. Not really that much of a danger unless they land in your eye (good luck getting carbide out of there, it’s not ferromagnetic like most steels), but still…cringe-worthy (talking from experience, done it as well, would not recommend unless very desperate)

Maybe this is your first time to HaD, but that basically sums up 80% of the projects on this site…so yeah. Thanks for visiting.

Interactive Map · Taxpayer Liaison · Property Tax Assistance · Property Tax ... Hidalgo CAD · Hill CAD · Hood CAD · Hopkins CAD · Jasper CAD · Jefferson CAD · Jim ...

ZIP Code 56307 is the postal code in ALBANY, MN. Besides the basic information, it also lists the full ZIP code and the address of ZIP code 56307.

I had a detailed response but I decided I you are not bright enough to understand basic conversation anyway so I won’t waste my time.

That is my favorite idea also with the smaller size adapter for more intricate cleaning coming in second. Reminds me of the hot water or sand PVC bending techniques also to save costs on joints and make larger radius bends.

Maybe other people would be willing to take that gamble (to each their own), but speaking for myself I would not. I’ve developed an appreciation and awe for the amount of energy individual people can harness every day, from observing failures (machine and human) and from running the math. Shit’s bananas, and the human body is nothing more than tissue paper to equipment like this.

Parameters such as the length of the destroyed fibers, the nature of fiber breakage, and the proportion of fractions of individual sizes are influenced by the behavior between the composite sample and the tool, material composition and structure, process conditions—the type of machining technology used, the angle of the tool face, and cutting conditions. In composite systems, reinforcing fibers are the dominant component of the material system due to their characteristic properties. At the same time, an important parameter is the way the fibers are placed in relation to the direction of movement of the cutter. Here, the polymer serves as a binder and mediates the transfer of forces between the fibers. Violation of the system, especially fiber breakage, must therefore be analyzed from the point of view of stress on the fibers, which leads to their subsequent destruction [34].

motonnerd: You don’t seem to understand the point of MY comment. vinito64 makes the comparison between $20k for equipment vs. $20k for fixing the damage, as if the $20k for equipment was an option. Which is fine if you’re working for a big company that can buy that shit FOR you, but is way out of reach for most individuals. And the number of examples of groups of people working together to make crap that will kill you goes way beyond your few examples. I fully understand the comparison he was trying to make, but it only illustrates his bias against people without unlimited resources, AND it starts with the premise that using a drill press in this way has some likelihood of causing more than $20k of damage, which as others have pointed out is just way beyond what’s likely.

Milling and miling capable machines either have a drawbar of some description to pull the taper tooling into the socket, from above or they have *something* that won’t come loose on the end of the quill (qc30 for example has a 1/4 turn capable only locking ring that grips the flange on the qc30 tooling pulling into the socket). Even a collet chuck *Screwed* onto the end of the spindle would perform this function. It just has to have something to stop whatever dropping off when turning without having a spanner or tool applied to it to loosen it.

Harbor Freight has one for $700.00 and Ebay for similar prices. For a couple grand you can set up a nice metal working shop with lathe, milling machine, grinder, etc. Won’t be fancy but something that is safe and functional.

Or keep working stupid and get hurt if or killed if you want. I honestly care not. I cared about my co-workers who got hurt & killed and we watch each others’ back as best we can to help keep ourselves safe as the winds allow – you’re a total stranger to me so I won’t mind at all when you finally realize this stuff matters.

The RPM is far to high for milling steel, it would work fine in softer materials with small diameter end mills. You then need to come up with a ridged way to hold the router and accurately move the router or the work in the Z axis. The high RPM scares the hell out of me. I can work next to my manual mill all day at 1000rpm. The 18,000rpm of my CNC router scares me. I typically don’t stand too close when its running. I’ve hit a clamp and sent them across the shop with the CNC router. It was like a gunshot going off.

Hey! For a motor/spindle these are pretty decent for your purpose: https://www.banggood.com/400W-DC-12V-48V-12000rpm-Air-Cooled-Spindle-Motor-Engraving-Milling-p-1051176.html?rmmds=search&cur_warehouse=CN They could be better as the bearings in them are mounted in a rubber or plastic bushing rather than the metal housing, which is a shame – they were soooo close. But for a small milling/drilling device they aren’t too bad and a fair bit better than a Dremel. You can also find them maybe cheaper and/or closer on eBay and maybe Amazon or the like as well. Search “DC motor collet” and some will pop up. The collets are ER-11 I believe, which is a standard machining thing and easy to find inexpensive sets or other desired sizes.

Plunge milling

Even if the milling doesn’t work out, you’d still end up with a miniature drill press with precision positioning via the X-Y platform and that would probably work fine.

Second is the Morse Taper (usually a #2 on models with a 1/2″ or 5/8″ capacity chuck). Cheaper drill presses may omit this and have the Jacobs Taper directly machined directly onto the end of the spindle instead of using the MT to JT arbor.

During machining, fiber and polymer dust comes into contact with the human body in the following ways: inhalation, ingestion, and skin contact. Toxicological studies on rats and rabbits confirmed an adverse effect on their health, but no significant impact on lung function was recorded. Fibers with a diameter of 7 μm and a length ranging from 20 to 60 μm at 20 mg/m3 did not produce systematic health problems in these animals, except for variable respiratory rates. In a study using carbon fibers made from pitch (so-called pitch fibers) with a diameter of 1 to 2 μm and a fiber concentration in the air of 47 or 106 mg/m3, transient inflammatory conditions were identified that returned to normal after the exposure ended. In other studies, carbon fiber and epoxy polymer dust were found to cause an apparent histopathological reaction in rats after an intratracheal dose [14,15,19,20,21,22,23].

[Eric] explains the concept of the cross slide vice, which is the piece of equipment that makes machining on a drill press possible. Essentially it’s a standard vice, but with screws that allow you to move the clamped piece in the X and Y dimensions under the drill which can already move in the Z dimension. For those counting along at home, that puts us up to the full three dimensions; in other words, you can not only make cuts of varying depths, but move the cut along the surface of the work piece in any direction.

Thanks. I do have Dremels, and some smallish mill bits to try; still looking for a suitable drill stand. The drill press fixture on that page is closer to US$80, and it holds a Dremel or a power drill… and once again we have a drill, which comments suggest is not suitable nor safe for milling. A drill press… I already have.

When grinding composite samples with carbon fibers, relatively long fibers with more than 120 µm were released, compared to the assumption. The length of the carbon fibers produced during grinding ranged from 0.14 µm to 127 µm (Figure 9). As in the previous cases, the fracture of the fibers was tough and at an angle perpendicular to the direction of the axis of the fiber. Even in the case of grinding, particles with dimensions below 1 µm were identified, as were more or less flat formations that had to be chipped off the carbon fiber surface (Figure 11). Formations of a similar nature were also identified in a previous experimental study [38].

Bearings are no different than the ones on my small lathe and mill. Issue is definitely the tapered chuck. A decent fix is to pull the spindle, take it to a real lathe and turn it down to 1/2-20 or 3/8-24 to thread on a chuck.

Glass fibers after removing the epoxy matrix. (a) Image of glass fiber destruction after drilling (n = 1000 rpm, D = 9.8 mm, and fn = 0.2 mm/min). (b) A close-up of the characteristic fracture surfaces of glass fibers after drilling (n = 1500 rpm, D = 5.0 mm, and fn = 0.2 mm/min).

[BrightBlueJim], I think you misunderstand [vinito64]’s point. I would be entirely unsurprised to hear that an errant chunk of end mill or drill causes over $20k in medical charges via any number of routes – chunks deep in the eye as mentioned below, medevac services because a larger chunk lacerated your throat and now you’re bleeding directly into your own lungs, etc. etc. Or, if you prefer, you can leave that nice chunk of carbide in your eyeball and probably lose the eye entirely, plus get a nasty infection.

The little tiny milling machines are not much better than a drill press. That is about all I use my X2 for these days. I picked up an old Deckel KF12 for less than what I paid for the X2 and its a whole different experience. Its far more ridged than even the SX3 I have at work. The KF12 isn’t even a really powerful mill. Its a pantograph machine that I’ve locked down to use as a conventional mill.

I used to have a “Big Red” 12 speed Drill/Mill from Harbor Freight. I made some neat stuff with it. Used it to fix up one of the earliest 7×10 lathes imported by Grizzly (serial number 346), and eventually sold it for more than I paid for it, in a package deal with a 10″ Atlas lathe that had a New-All quick change gearbox.

Many of the low end drill presses don’t use thrust bearings in the quill. They use radial figuring that the allowable axial load won’t be exceeded. These can handle a lot of lateral, within the limits of a small, likely soft spindle shaft and low rigidity for the quill. They are good for the drill press sanding drums (other considerations apply) and light lateral loads.

The run-out on this video from blown bearings is cringe worthy, and one could buy 2 mills with the number of bits he probably broke already. People also used to make tires out of wood, but it does not mean people should… =)

Milling is all about having ridged constrains on all 3 axis. With out that you might as well do it by hand. To get rigidity you need mass. My milling machine weighs nearly 4000lbs. The CNC router weighs something like 2800lbs.

[Eric Strebel] is quickly becoming a favorite around these parts. His well-produced videos show viewers the practical side of product design and in-house manufacturing. We recently covered his video on doing small-scale production, and there’s plenty more invaluable info to be had browsing back through his older videos.

During the selected machining processes implemented on the prepared composite samples, the primarily occurring chips fragmented into smaller particles—dust, which is made up of fibers and a polymer matrix—appears. Both the polymer matrix and the destroyed fibers showed potentially harmful dimensions for health. However, the stability of reinforcing fibers, both carbon and glass, is greater than the stability of the polymer used;

Flying drill press chucks are scary common if you try and mill. I investigated after having two loose chucks. I can confirm that the repetitive side forces are almost designed to loosen a drill press chuck, even when super tight and lightly loaded. A common mill spindle is designed to pull the collet up as you tighten a large nut at the top of the spindle. A drill press usually is just a wedge fit that gets tighter as you press the chuck down, and looser as you wobble it sideways. Do not do this unless you plan for ruined work and flying two pound chucks hitting you in the face. If there is a decent solution to this safety problem please advise and I will try it as I don’t care about the bearings and the chatter and the poor control. Sometimes it is still fun to make things work the way we want them to even if it under performs.

The dimensions of destroyed glass fibers range from tens/hundreds of nanometers to hundreds of micrometers. The minor average fiber lengths are generated during grinding (29 µm), and the longest, on the contrary, during milling (52 µm). Fiber breakage is fragile, perpendicular to the fiber axis or at an angle;

Composite materials with carbon and glass fibers in an epoxy matrix are widely used systems due to their excellent mechanical parameters, and machining is a standard finishing operation in their manufacture. Previous studies focused exclusively on the characteristics of the fibers released into the air. This work aimed to analyze the nature of the material waste that remains on the work surface after machining. The dust on the work surface is made up of fibers and a polymer matrix, and due to its dimensions and chemical stability, it is a potentially dangerous inhalable material currently treated as regular waste. The smallest sizes of destroyed carbon fibers were generated during drilling and grinding (0.1 μm), and the smallest glass fiber particles were generated during milling (0.05 μm). Due to their nature, carbon fibers break by a tough fracture, and glass fibers by a brittle fracture. In both cases, the rupture of the fibers was perpendicular to or at an angle to the longitudinal axis of the fibers. The average lengths of destroyed carbon fibers from the tested processes ranged from 15 to 20 µm and 30 to 60 µm for glass fibers.

In the case of milling composite samples with glass fibers, the length of the fibers ranged from 0.065 µm to 683 µm (Figure 12). The fibers broke perpendicularly and at an angle to the fiber’s longitudinal axis. The images from the electron microscope showed many small particles created by the destruction of fragile glass fibers, with dimensions in units of micrometers.

Grinding was carried out with cutting conditions (n = 2400 rpm, ap = 0.2 mm, and vf = 200 mm/min). During the grinding of the glass fiber composite samples produced particles ranging in size from 0.31 µm to 220 µm (Figure 18). In Figure 19a, it can be seen that during the grinding of the fiberglass composite, chips were formed in the form of long bundles of matrix-coated fibers. Figure 19b shows a single fiber with pieces of matrix adhered to it. After burning the polymer matrix, tiny particles of glass fiber resulting from their destruction with dimensions ranging from hundreds of nanometers to tens of micrometers were easily identifiable (Figure 20a,b).

The advantage of composite systems is given by using carbon and glass fibers located mainly in a polymer matrix, i.e., materials with entirely different properties, which leads to problems in machining technology caused by the connection of such materials [8,9,10,11,12].

The length of the carbon fibers produced during the drilling process ranged from 0.12 µm to 73 µm (Figure 6); the fibers were broken similarly as in the case of milling, i.e., at an angle of 30° to 60° towards the axis of the fiber, so perpendicular to the axis (Figure 7 and Figure 8). After removing the particles of the epoxy matrix by burning, tiny particles with sizes below 1 µm, i.e., hundreds of nanometers, which adhered to the surface of the destroyed carbon fibers, were visible on the microscopic images. The smallest carbon fiber particles ever identified were in the drilling process. This size of the particles is already very problematic because, according to the literature, these are inhalable particles that can enter both the alveoli and the bloodstream [18,19].

The Occupational Safety and Health Administration (OSHA) defines respirable dust as particles that are small enough to enter the nose, upper respiratory tract, and lungs. The National Institute for Occupational Safety and Health (NIOSH) considers fibers less than 3.5 μm in diameter respirable. The Mine Health and Safety Administration (MHSA) considers aerodynamic dust smaller than 5 μm respirable. According to the MHSA, 25% and 90% of dust are respirable if their aerodynamic diameters are equal to or less than 5 μm and 2 μm, respectively. The average concentration should be kept below 15 mg/m3. Other publications give limits of 10 mg/m3 for total airborne particulate mass and 5 mg/m3 for 8 h of exposure [20,29,30,31].

Look being a Machinest for over 20 years n a millest at that n having used my small drillpress as a milling tool don’t take large cuts use ur head there’s a depth for each type of metal being milled take ur time don’t be a gorilla n I’ll be fine..

Glass fibers in epoxy resin. (a) Image of a bundle of glass fibers and matrix particles after grinding (n = 2400 rpm, ap = 0.2 mm, and vf = 200 mm/min). (b) Close-up of the glass fiber and matrix particles.

Glass fibers after removing the epoxy matrix. (a) Image of glass fibers and fragments created after milling (n = 1000 rpm, ap = 2 mm, and vf = 100 mm/min) with a characteristic brittle fracture in a white circle. (b) Close-up of glass fibers and their fragments.

Chip machining, milling, drilling, and grinding were selected for fiber destruction in epoxy resin/carbon fiber and epoxy resin/glass fiber composite systems. Milling was performed on an FNG 32 milling machine (TOS Olomouc, s.r.o., Olomouc, Czech Republic) using a cylindrical end mill with a diameter of 80 mm and seven replaceable inserts, TNGX 100404SR-F (Dormer Pramet, s.r.o., Šumperk, Czech Republic). For milling, the rotation speed n = 1000 rpm, depth of engagement ap = 1 mm and 2 mm, and feed rate vf = 100 mm/min were selected. Drilling was carried out on a FNG 32 machine (TOS Olomouc, s.r.o., Olomouc, Czech Republic); HSS-Co DIN 338 drills with a diameter of D = 5 mm and 9.8 mm with a tip angle of 118 ° were used for the experiment (Oren, s.r.o., Údlice, Czech Republic). The following cutting conditions were chosen for the experiment: revolutions n = 500, 1000, 1500, and 2000 rpm, and shift per revolution fn = 0.2 mm/rev. Grinding was carried out on a TOS BPH 320 A/100 surface grinder (TOS VARNSDORF, a.s., Varnsdorf, Czech Republic), with a grinding wheel T1 250 × 32 × 76 98A60K9V40 421188 (TYROLIT CEE, a.s., Benátky nad Jizerou, Czech Republic). The rotation speed n = 2400 rpm, the feed rate vf = 200 mm/min, and the engagement depth ap = 0.2 mm were selected. The cutting conditions were determined according to industry practice. No process medium was used in the experiments.

The only things I’ve ever turned in my drill press is a small piece (1/8″ thick and about 2″ long) piece of poplar dowel to make a model cannon for a Napoleonic army diorama. I used a piece of fine grit sandpaper glued to a tongue depressor to shape the wood.

Ben: Likely, but not a guarantee. Most current low end drill presses have no retention other than the taper. Fine for drilling, not for lateral. Some current and many older models (older means pre Taiwan imports in the 1970’s and 80’s) have a retaining collar for the chuck that threads on to the end of the spindle. These can take a lot of lateral. as long as the collar is snugged. If you want to see an example, MrPete recently did a video showing one.

Illustrative image of chips generated during the selected machining process (left) and after removing the epoxy matrix by firing it (right) for carbon fiber (top) and glass fiber (bottom) systems.

This random image looks similar – how are those bearings not able to take the relatively light lateral forces involved here? http://photobucket.com/gallery/user/akg414/media/bWVkaWFJZDoxMDU1OTQwNTE=/?ref=

Millbit fordrill press

HaD comments never cease to amaze. I wonder how many people leaving these long rants even bothered to watch the linked video. The guy is “machining” plastic and wood, maybe some lightweight alu like the PC heatsink in the picture. Nobody is suggesting that you try and cut steel, or even saying it’s a very good solution, but if you’re trying to route out holes in a block or foam or something, you don’t need to go out and buy a proper mill for that kind of action.

Here’s a thought – you could figure out a way to mount a Dremel motor (or whatever) to the quill of your drill press so you have the table and quill (the outside, up/down part of the housing of the spindle). This would give you the table and up/down motion but bypass the dangerous part of the drill press. It might work for some experimenting at least.

Those were my first thoughts, when I heard “machining on a drill press”. The main tip is don’t. The bearings aren’t designed for lateral forces. You may as well just twist drills instead of mill bits, since they aren’t designed for lateral cutting either. It won’t work well, but you get extra points for doing two things you shouldn’t.

When machined at an angle (45°/135°), the cutting force is distributed into a cutting force perpendicular to the fiber direction and a cutting force parallel to the fiber direction. Fibers are affected by compressive and tensile forces—fibers in direct contact with the tool are stressed by pressure while stretched on the other side. Cracks appear, and fibers are pushed, pulled, and bent simultaneously. Cracks formed on one side of tensile stress propagate easily, while cracks on the other side of compressive stress propagate poorly. As a result of these forces, the fibers crack and split. At the same time, the fragile resin is destroyed under pressure, tension, and bending; the matrix carries compressive stress and creates compressive deformation. As a result, cracks propagate perpendicular to the direction of the fibers in the interface region, and in some cases, longitudinal destruction of the fibers may also occur [19].

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

Hah! No kidding. I probably could have pared it down to half the words too if I was any good. I found three more errors, but they don’t affect the content. I think I’ll go do some machining now ;)

Some shop are dangerous more than you want to share from experience as you do not have the experience. I’ve not directly witnessed events, nor am I acting like I watch Faces of Death or Snuff videos… still… there are cases if you search the internet for strange events that have killed or maimed people. Without a doubt.

The problem with using a drill press isn’t the bearings at all other than wear may cause them to have play which will probably cause vibration (chatter) eventually. While they are typically much lighter-duty than a drill press and not specifically designed for radial loads, it’s also not a big deal to replace the relatively cheap worn bearings in a drill press anyway and it would take quite a lot to wear them out, so the bearing issue is almost entirely a myth. Milling machine bearings aren’t always, but are often much more expensive (like $300 – $700 for a set on a spindle), but since they are designed for the job, they last a very long time too.

Except that what you are turning down to thread is a MT taper that fits into the actual spindle. The whole notion is ill advised, and frankly stupid. Do Not put side loads on anything held by a taper.

When machining in the direction parallel to the direction of the fibers (0°), the tool moves at a certain speed, and the interaction between the tool face and the material generates the main cutting force. The cutting force is decomposed into a force parallel to the fiber direction and a force perpendicular to the fiber direction. A force perpendicular to the fiber creates compressive stress on the fiber; the fibers are pushed, bend to both sides (buckling), cracks appear in the tensile stress points in the fibers, and the fibers break. The fragile polymer matrix surrounding the fibers is also stressed, cracking and breaking into small particles.

End Mill DrillBit

How the cheap drill/mills get around the issues of the Morse Taper is they bore the spindle for a ~ 1/4″ diameter drawbar, usually with a larger bit of threaded rod welded onto the bottom end so normal Morse Taper tool holders can be used. That causes the annoying ‘feature’ of having to load and unload the drawbar from the bottom. That’s a real PITA when you have to switch between milling and drilling, especially with a round column that allows the head to pivot sideways when unclamped to adjust the height.

FINALLY, an constructive alternative, instead of a useless “don’t do this” comment. Routers use a collet chuck instead of the murderous taper-mounted wedge chuck. The challenge, I guess, is the third axis. You can put an X-Y table under it, but you somehow have to position the router bit in Z.

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after the thermal removal of crushed epoxy resin particles. It was found that the shortest fibers that are generated using this technology have a size of 0.3 µm, the longest fibers have a length of 114 µm, and the average length is 19 µm (Figure 3). The conditions chosen for this technology (number of revolutions per minute and engagement depth) do not have a fundamental effect on the length of the generated fragments.

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after chip burning, which removed the epoxy polymer. It was found that the shortest fibers generated using this technology have a length of 0.15 µm, the longest fibers have a size of 130 µm, and the average length is 20 µm (Figure 9). Other process conditions were not experimentally evaluated within the grinding technology.

Bah! Another correction… The sentence “While they are typically much lighter-duty than a drill press” should read “While they are typically much lighter-duty IN a drill press”

When machining composite materials with carbon and glass fibers in epoxy resin, chips of typical shapes and sizes were formed according to the chosen technology (milling, drilling, and grinding) (Figure 1). Chips of a more or less compact nature were composed of epoxy resin and reinforcing fibers and fell into smaller fragments after handling. The fragments were formed by an epoxy matrix crushed into larger or smaller particles with dimensions of units up to hundreds of micrometers, which had greater or lesser adhesion to the reinforcing fibers. Both glass and carbon fibers were chopped to lengths ranging from hundreds of nanometers to tens of micrometers. The nature of fiber failure generally varied according to the type of fibers used—carbon fibers showed a tough fracture, and glass fibers showed a brittle fracture. The fiber length and the number of individual fractions varied according to the machining method and conditions.

Dust particles created after machining composite parts are made of crushed fibers and polymers and vary in size and concentration in the surrounding environment. The amount of composite dust generated during the machining process depends on the machining process type, material removal rate, tool speed, tool material, and fiber orientation in the composite system. For example, increasing the cutting speed and decreasing the feed rate reduces the number of particles in the surrounding environment [18].

From the presented analysis, it is evident that tiny particles, potentially hazardous to health, were found even in the waste that remains on the work surface after machining. Particles released into the air during the processing of composite materials, even those that stay on the work surface, have dimensions comparable to those of bacteria and viruses and can quickly enter the human body [39,40].

On top of that, a drill chuck is designed to hold a wide range of bit sizes and the way it does that is collapse in on the tool with basically a pointed “V” on each of 3 jaws. A milling tool holder (collet) is made to hold only one size and you use one made to specifically fit the size of the cutter. This necessitates the need for a set of them to fit a range of cutter sizes, but it holds firmly and more safely. In a drill chuck, the hard steel or carbide cutter is likely to slip in or out and may trash your part dimensions or maybe the part altogether. In this regard, you’ll PROBABLY notice things going awry before things really go bad and get unsafe, but you never know.

I totally agree with you, I have been wanting to get into mechanical milling as a hobby. It is cool how you can use a drill press as a small mill. This is nice so that I can pick up work on a project that I would need a mill and lathe for.

This publication was written at the Technical University of Liberec, Faculty of Mechanical Engineering, with the support of the Institutional Endowment for the Long-Term Conceptual Development of Research Institutes, as provided by the Ministry of Education, Youth, and Sports of the Czech Republic in the year 2019.

201931 — Wearing nylon underwear or tight yoga pants can block air movement in the vaginal area, which can cause increased bacteria growth. Heavily ...

The shaft in a drill press isnt sufficient for lateral forces and will bend slightly. Rotation with the shaft bent will wear i out very fast and it will break.

Don’t get me wrong, I like using things in creative and novel ways. But using a Harbor Freight drill press as a lathe starts to get into the territory of just plain ill advised. You can skimp on things but only to a point and this feels like it is getting awfully beyond where you should be advising others to generally go as a normal type of thing.

Seriously, hackaday, employ someone who knows enough about engineering to not post stuff that will get your readership in trouble. In another article you mention that the people who do good engineering in small hobby shops dont come to HaD very often, well this is why.

Center cuttingend mill

Glass fibers in epoxy resin. (a) Image of the chip after milling (n = 1000 rpm, ap = 1 mm, and vf = 100 mm/min) with broken glass fibers and matrix particles. (b) Close-up of broken glass fibers with matrix particles.

Isn’t a router used by some for the reason to avoid issues in the X-Y direction failures on the equipment and causing injury. I’ve used a drill press for wood and plastic before… which is like a pathetic though worked grooving material with a hand drill. Not the best for longer use or harder materials. HaD surface grinder would be interesting. Strange on some days when I can look at tools my Dad made since certain equipment is just not best used long term for certain tasks and we can make even better versions of those tools. Challenging looking at the cheap harbor freight lathes that we were talking about converting to make tighter tolerance and I was even thinking going all the way to make CNC with. Reminds me a safety and cost shear reminders when custom making to design in failing for safety at points and save money on replacing parts. Even yard tools have to be custom made or upgraded if used for longer term. I have to buy 10′, 3/4 to 1″ black pipe and cut in hand and make custom handles for yards tools since I always tend to break them.

Fibrous solid carbon structures with a length-to-thickness (diameter) ratio greater than or equal to 3 μm are respirable and may cause chronic discomfort [15,24,25,26,27,28].

Conceptualization, D.K. and Š.D.; methodology, Š.D.; validation, Š.D.; formal analysis, Š.D.; investigation, A.K. and T.K.; resources, A.K. and T.K.; data curation, A.K.; writing—original draft preparation, D.K.; writing—review and editing, T.K. and A.K.; visualization, A.K.; supervision, Š.D. All authors have read and agreed to the published version of the manuscript.

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

Interesting read though. Brings back memories that anger me a little. More about moving to the UP of Michigan to go to Tech and those UP mafia idiots (traffickers, miner dangerous, hitmen hideouts and prisons anything) and Axis War Criminal Camps descent that are still no way rehabilitated or anything U.S. interest other than murdering anything they can and stealing whatever they can… targeting anything that is smarter and doesn’t molest like they do. Yeah, at one time industrial machine repair (screw machines mainly) was a thought till somehow they brain damaged my Dad along with their “trolling” inbreds downstate that playcate with their Roman f-up hoards. Maybe they’re the Polac Navy Project Sanguine idiots.

That Proxxon XY table is NOT cheap. That EU company is very proud of their entire product range, even the items that are cheaply made.

I see that you left basically this same comment on the creator’s YT video, and his answer seemed very fitting. We all know that a drill press is not a mill, nobody has claimed otherwise. Nobody has learned anything from these comments you are leaving, and the idea that the post should have an addendum about how you personally corrected their ignorance would be funny if it wasn’t so incredibly narcissistic.

It’s cheaper from a dollar amount though. Though maybe not from a time perspective. Plus the results will usually never be very good in comparison to doing it in a more traditional or proper method. Plus it can be considerably more dangerous.

Chromium carbide coatings result in a dense, well-bonded, very hard coating that is well suited for fretting and abrasive wear and hard surfacing.

p: I think you may be talking out the wrong end of your alimentary system. All drilling machines are designed to take axial loads, and every drilling machine I’ve ever seen had some kind of bearing designed to bear the axial load. If they didn’t, they wouldn’t survive the first big hole you tried drilling with them. You are not making sense.

The downcut force will also pull hard shank end mills loose from drill chuck jaws. The hard jaw surfaces with three small contact lines on the hard shank surface of an end mill = very poor grip.

Composite systems based on carbon and glass fibers with reactive plastic matrices are, thanks to their mechanical parameters, widely used materials in many industrial areas, starting with the aerospace industry and ending with sports needs [1,2,3]. Composites are predominantly used in engineering structures due to their higher mechanical properties, superior durability, and fatigue performance. Many relevant studies provide not only an extensive scientific background but also state the current state of the issue [4,5,6].

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after the thermal removal of the epoxy matrix. It was found that the shortest fibers generated using this technology have a size of 0.310 µm, the longest fibers have a length of 220 µm, and the average length is 29 µm (Figure 18). Multiple technological conditions were not evaluated in this experiment.

A Nikon EPIPHOT 200 optical microscope (Nikon, Minato, Japan) with the NIS-elements 5.02 program was used to evaluate the micrometer lengths of the fibers. The electron microscope TESCAN MIRA 3 (TESCAN Holding, Brno, Czech Republic) was used to monitor sub-micrometer fiber lengths, assess the nature of fiber fractures, and describe the nanometer and sub-micrometer particles produced during the machining process. The surface of the samples was sputtered with a layer of Pt-Pd (Quorum Q 150R ES) with a thickness of 2 to 4 nm.

Yes, the chuck could fall out. Somebody even linked to the AvE video where it happens. Guess what? The chuck falls down an inch, makes some noise, probably screws up whatever you were working on, and that’s that. Where can it go? It’s still going to be in the taper, just not engaged. The chuck would have to fall down ~5 inches before it came out of the taper, but it’s going to be in direct contact with the piece your working on so it won’t have the room.

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after the thermal removal of the epoxy polymer. It was found that the shortest fibers generated using this technology have a length of 0.07 µm, the longest fibers are 683 µm, and the average length is 52 µm (Figure 12). The conditions of the selected technology (speed and depth of engagement) do not fundamentally affect the length of the generated fragments.

“There have been many different approaches to solving the issue” should instead read “There have been many different approaches to trying to at least somewhat increase the ability to solve an issue while not really properly solving it while also introducing a number of downsides and potential negative things at the same time”.

You can even turn down a (small) piece of round stock by placing it in the chuck of the drill press, and putting a good chisel in the cross slide vice. The chisel can then be moved up against the spinning piece to make your cuts. We don’t suggest doing anything too heavy, but if you need to turn down something soft like a piece of plastic or wood to a certain diameter, it can do in a pinch.

EVERY damn time someone mentions milling on a drill press you get the same old tired “read-it-on-the-internet” replies. “The bearings are not designed for lateral forces” do you all feel smart for using the word lateral? Have you tried it and failed? I have found that some machinists tend to be snobs frankly. Hung up on a couple thousandths of an inch etc. There are MANY home projects that could use a half shitty milling operation. I myself started with an old Craftsman drill press from 1948. It must weigh 150 pounds. I bored out the end of the quill housing to accept 2 bearings on the chuck end. Got a cross slide vice that needed some corrections…for as much as one is able to make chips with such a setup, CHATTER will be your main enemy. Stop worrying about those bearings that cant withstand lateral forces. Gee if I wreck my bearings, Ill have to spend $15 on another set and 45 minutes changing them out. Darn. CHATTER is what I need to work on. The chatter rattles my teeth long before my J2 chuck comes flying off the taper. IF you take a $50 harbor freight drill press and try it……not sure you will have much success…..they can barely drill a hole. I can mill aluminum if I take it a little at a time….Plastic of course is fine. Stainless sucks. I want to modify the chuck to accept a collet. That will be key. and if I fail, I fail. I will NOT spend $$$ on some piece of crap import. What I end up with will be as good. And besides, the journey is fun. Yeah, if I hawk marketplace and had $2500 to spend, and 3 phase in my shop, and could move a several thousand pound machine, Id buy an old bridgeport. Maybe someday.

To tell if your drill press has a Morse Taper, extend the quill and look for a tall, narrow slot in each side. Rotate the chuck and look for a slot through the spindle. If there are no slots in the quill then the spindle *may not* have a Morse Taper. It could be the slots were left out to save money on machining the quill, with no intention of making the arbor removable (without first removing the spindle). If you see a slot through the spindle then it almost certainly has a Morse Taper.

The quest to do machining without actually having a machine shop is certainly not new to Hackaday. There have been many different approaches to solving the issue, but picking up a decent drill press and cross slide is a first step down the rabbit hole for most people.

A standard laboratory furnace fires epoxy resin from chip samples from individual machining processes. The burning temperature was 500 °C ± 10 °C, and the burning time was 2 h.

During the milling of composite samples under the given cutting conditions (n = 1000 rpm, ap = 1 mm, and vf = 100 mm/min), carbon fibers were shortened to lengths ranging from 0.3 µm to 115 µm, undercutting conditions (n = 1000 rpm, ap = 2 mm, and vf = 100 mm/min) produced fibers with a length ranging from 0.3 µm to 94 µm (Figure 3). In both conditions, fiber splitting occurred both perpendicular to the fiber axis and at an angle of 30° to 60° to the fiber axis (Figure 4). The particle size of the polymer matrix generated during milling ranged from units of micrometers to hundreds of micrometers. Carbon fibers were broken by a tough fracture in all machining cases (Figure 4a) are typical cases of such fractures. After firing the polymer matrix, small particles formed by destroying carbon fibers with dimensions in units of micrometers were visible. Even smaller particles, at the level of hundreds of nanometers, were also identified (Figure 5). From the picture in Figure 4b, atypical destruction of the carbon fiber is also visible—the longitudinal part of the fiber—“bundle of graphene layers”—parallel to the axis of the fiber has been torn off.

I have done some milling using an end mill in a chuck, in a milling machine, when I needed to do something quick and didn’t want to bother with the collet. The chuck fell out exactly as described, but didn’t go flying because it couldn’t fall far enough to clear the taper. Nothing much happened, but I could see the end mill striking the work and breaking (if you’re machining a hard material, which I wasn’t) and sending bits of metal flying. Thanks to the comments here, I understand why the chuck fell and won’t be so lazy in the future.

In both cases, tiny glass and carbon particles with dimensions below 2 µm and hundreds of nanometers are formed. From a health point of view, particles smaller than 2 µm are potentially the most harmful. Particles of these dimensions tend to penetrate the respiratory tract; the smallest particles can reach the alveoli or bloodstream [18,19]. In industrial companies, workers processing composite materials use FFP3 respirators, which have the lowest allowed overall efficiency of 98% at a size of 0.36 µm;

1 MGIVR2016-1.5 turning tool holder. 1 wrench. Tool holder material: carbon steel. Tool holder model: MGIVR2016-1.5. Insert model: MGMN150-G. Insert ...

Image of prepared composite samples and chips from them during the machining processes of milling, drilling, and grinding (from left to right). Carbon fiber composite samples (upper row), glass fiber composite samples (lower row).

vinito64: oh, so now you play the “I’ve got way more experience than you” card. Okay, in those thirty years, how many times have you seen a chuck come off and do $20,000 worth of damage? Ditch the hyperbole, and give me the benefit of your actual experience.

vinito64: To many people, saying “It doesn’t matter if a milling machine cost $20 grand because that is a pittance compared to the cost of serious injury just in dollars alone”, is tantamount to saying “if you don’t have $20,000 to blow on a machine, you must never make anything that requires a lathe or milling machine.”

This was some smart stuff. The critical comments are worthless to me and are comments that like those who can’t swim, either learn or get out the boat.

When machining perpendicular to the fiber’s direction (90°), the main cutting force is perpendicular to the fiber axis. It can be decomposed into the cutting force in the fiber plane and the cutting force perpendicular to the fiber plane. The fibers are stressed by pressure at the point of contact with the tool and can form cracks; on the opposite side of the fiber, there is tension and subsequent breakage. The polymer matrix is subjected to pressure in front of the cutter, and cracks are formed. The fragile matrix is crushed into small particles.

HHhmmm… yes, a router head would be more suitable for harder materials. Not sure the chuck in the router is the best… still. I’d figure on making a shield or guard around for safety reasons if needed. I’ll have to read into and see what is on the market. Wasn’t there someone making an open source mill from a router somewhere I recall?

Guys, sometimes it is NOT a morse taper! Sometimes it’s a taper about 78ths of an inch long and the chuck comes out, like out for real, the cutter hits the work piece and flies off horizontally and permanently removes your front teeth, but don’t worry, as it turns out you don’t actually need them!

Now, in regards to stories I haven’t directly witnessed the effects from other than missing limbs… there is the missing fingers from screw machines, steel rolls and rollers and presses (I think I’ve met people though am not in detail recalling who at the moment) and holes from high current high voltage not putting their one hand in their back pocket. I got the saw that “beep” and be carefully this and that every time I’d do anything or my Dad would even do electric work… No gloves, no long sleeves, when I had long hair that had to be in a pony tail tied back in the machine shop. I had to be on site as the first responder ready to resuscitate, transport, get transport or treatment, treat or the one that I wasn’t as sure about in regards to household (I think seeing at work scared him bad from the stuff he saw as a union steward and maintenance) knock him off with a 2×4 if he got stuck on the live line. Strange to me on some days. When you see accidents that kill or maim real bad… you get rather picky and can think worse case scenario and error on overboard. I think there used to be more drunks on the job and on drugs too at one time issues also. Same goes with emotional pervs or cheating issues. More not wise or not logical issues.

When grinding composite samples under cutting conditions (n = 2400 rpm, ap = 0.2 mm, and vf = 200 mm/min), the fibers were shortened to lengths ranging from 0.15 µm to 127 µm (Figure 9). Fibers have shortened perpendicular to the fiber axis during grinding (Figure 10 and Figure 11a), at an angle similar to milling (Figure 4 and Figure 5). The size of the polymer matrix particles released during grinding ranged from units of micrometers to tens of micrometers; despite the fact that the sample was destroyed by machining, very good adhesion of the matrix to the carbon fibers was evident. As in previous cases, the carbon fibers broke through a tough fracture (Figure 10 and Figure 11b). After burning the polymer matrix, tiny particles of carbon fiber resulting from their destruction with dimensions ranging from hundreds of nanometers to tens of micrometers were easily identifiable (Figure 10 and Figure 11). In the picture in Figure 11b, very thin layers released from the carbon fibers are visible.

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after the thermal destruction of epoxy resin particles. It was found that the shortest fibers that are generated using this technology have a size of 0.12 µm, the longest fibers have a length of 75 µm, and the average length is 13 µm (Figure 6). The conditions of the selected technology (drill diameter and revolutions) have an effect on the size of the generated fragments.

Dust particles created during the machining of composite systems and subsequently detected in the air differ in their dimensions and quantity. The so-called aerodynamic diameter of the particles that are usually released during machining was determined (the aerodynamic diameter of a particle is the diameter of a sphere with a density of 1 g/cm3 with the same final velocity caused by the force of gravity in still air as the particle has under the usual conditions of temperature, pressure, and relative humidity). It has been found that particles larger than 10 μm can be trapped in the nasal cavity. Particles with an aerodynamic diameter range of 5 to 10 μm are inhalable and settle in the nasopharynx region. Particles 2 to 5 μm in size can enter the trachea and bronchi; particles smaller than 2 μm can enter the alveoli; and particles smaller than 1 μm quickly enter the bloodstream. In many studies that have addressed this issue, fiber and polymer dusts have been found to cause a definitive histopathological response in the lungs of rats following an intratracheal dose.

Having said that, Dremel tools are notorious for having flimsy bearing mounts, i.e. the bearings just fit in a recess in the plastic housing. So it is probably going to inevitably and annoyingly vibrate way more than you want. But you still may be able to do some light stuff.

I have done several one offs in the drill press in wood with a Dremel and burr bit as the tool bit. It does all the work and the drill press just turns.

Since the problem is the solely friction fit of a taper mount, a (kind of) solution is to figure out a way to mechanically retain the taper in the spindle, such as a taper pin, large set screws or something else mechanical. It’s still not great since pins or set screws are still much smaller (less strength) than a drawbar typically used in a milling machine, plus you’d have to do it in such a way that the retaining method at least holds the taper securely and better if it slightly pulls in in, all while not damaging the tapered bore (or making sure all burrs are removed). Still, tons safer than nothing. Not super simple, but could be done and while not totally eliminating danger, reduces it by a magnitude at least.

In the case of composite samples with glass fibers, particles with dimensions from 0.25 µm to 398 µm were formed (Figure 15). Glass fibers were broken by a brittle fracture perpendicular to the axis of the fiber (Figure 17). Sub-micrometric particles have also been identified.

Bah! the sentence “GAAAH! It’s highly risky and likely to go very well” was meant to read “NOT go very well” And since I’m here I’d like to add that since a drill press is typically not nearly as rigid as a milling machine, it’s more likely to start vibrating maybe a little or maybe more, and vibration will increase the chance of the tapered fit working loose. Oh the humanity. Just please don’t.

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Both machines were not much to look at, but under all the dirt they were both functional. I had to replace the motor on the mill. The lathe might some work in the quick change gear box. I may have to make a new gear or two for it. Its currently functional but running rough.

It's incredibly light-weight, extremely durable, and won't corrode in salt-water over time. It fits in the back of your wetnotes and you can carry it with you ...

MiniMill

Just buy a milling machine. It’s cheaper than paying for a doctor to patch you up because you used a drill press for something it was never design for.

If you’ve worked in a corporate environment that is driving the cost of insurance and health care related expenses… the goal is to have “Right the First Time” and “Zero Accidents.” You design systems to mitigate the risk that say I did witness directly that my Dad would either come home shook up and warn to me in more detail than I wanted to know or have to care for him.

The quantitative relationship between parameters such as the length of the destroyed fibers, the nature of the fracture, and the size of the fractions of individual dimensions can be summarized as follows: carbon fibers are crushed to smaller dimensions than glass fibers under the used machining technologies and conditions. The observed sizes of the destroyed carbon fibers range from hundreds of nanometers to about 130 μm; in the case of milling, they have the most significant representation of fibers with an average length of 19 µm, in drilling 13 µm, and in grinding 20 µm. The fracture is always at an angle to the fiber axis or perpendicular to the axis. The technology and machining conditions do not significantly affect the length of the resulting particles or the nature of the fracture. Destroyed glass fiber particles range from tens/hundreds of nanometers to hundreds of micrometers. In the case of milling, fibers with an average length of 52 µm have the most significant representation in the cases of drilling with 37 µm and grinding with 29 µm. The fibers break brittlely, at an angle, or perpendicularly. The lengths of broken carbon fibers are almost half those of glass fibers; the angle of refraction is analogous. The explanation for the significantly lower values of the sizes of the destroyed carbon fibers lies in their morphology, i.e., in the different values of Young’s modulus of elasticity in the axial direction, where it reaches between 250 and 380 GPa, and in the radial direction, in which it has values of 10–20 GPa. In contrast, the modulus of elasticity of glass fibers, as an isotropic amorphous material, reaches tens of GPa in all directions. When machining layered composite systems, the tool will interact with the fiber in the axial and radial directions, so it is clear that in the radial direction, the carbon fiber is more fragile than the glass fiber, and therefore its destruction will be easier. As part of the implemented chip machining experiment on multilayer samples made of carbon and glass fabrics, the technology and machining conditions did not significantly affect the average lengths of the destroyed fibers. For a better understanding of the processes and effects, it would probably be more appropriate to work only with a single-layer material of parallel fibers, where the effects of the machining conditions would be noticeable. In the case of layered materials, there is a combination of effects, stress, and deformation of the fibers at an angle, and the effects of conditions and technologies become challenging to grasp. When drilling a multilayer sample with carbon fibers, the lowest average values of the lengths of the destroyed fibers were measured, probably also because the intruding chip could continue to grind in the drilled hole.

Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

So sure, saying “this can be done, but it carries substantially-increased risk and is not recommended” is probably better (and more in the spirit of Hackaday) than “don’t ever do it”. We can probably agree that “don’t ever do it” is an oversimplification, but I think it’s a reasonable one for the following reason: By the time someone knows enough to assess the risks inherent with doing it, they will see the simpification for what it is. In the end, pretty much everyone it stops from doing this are the people who lack the knowledge and experience to understand the risks they are taking.

In both cases, machining conditions and technologies had no significant influence. Their mechanical parameters considerably impact the length of the destroyed fibers.

So you should conclude that just the picture shown in the authors article caused me to cringe. Just the sight of a photo of an endmill mounted in a drill chuck on a drill press makes me shudder. GAAAH! It’s highly risky and likely to go very well, but can easily lead to injury.

“they might just help some of the newer players get the most out of what they have access to” The ignorance of the danger here is evident from both Mr. Stobel and the author of this article. The poor “newer players” are better served by clearly explaining why NOT to do this rather than encourage them to experiment this clearly dangerous methods. What they “get the most out of” trying this might be way more than they bargained for. It is my opinion that this article NOT be deleted, but an addendum added AT THE TOP about what everyone involved didn’t know and what they learned by having it posted here. That would serve the readers well rather than keep them ignorant. The fact that you didn’t know is not surprising. Believe me, I understand why this seems to look like a lightbulb idea maybe – a drill press looks so similar in form to a milling machine. But there are important differences. I thought the same thing when I was young (yes, I did this with wood once, and yes it came loose within less than a minute and no, luckily I was not injured).

2021113 — Low alloy bainite martensite steel has attracted extensive attention as a wear-resistant material because of its high hardness and sufficient toughness.

Quite a leap to label me as an elitist for pointing out a danger that was evidently overlooked by both the author and Mr. Strebel. You totally missed my point. I wasn’t saying that everybody should just go blow $20K on a milling machine and “do it right”. I OBVIOUSLY was saying that once you mangle a tendon or few in hands or arms (easy to do) or lose an eye, then milling on the cheap with a Morse taper spindle becomes a regret rather than the clever idea you thought it was. If $20K sounds like a lot of money (and it IS), then how does it possibly make sense to take the chance of it easily costing that much in medical bills to fix you if you get seriously hurt? Being aware of a danger then deciding to just go ahead and hope nothing goes horribly wrong is not a bright idea, but if folks want to do it anyway then that’s their choice. I won’t laugh or exclaim “I told ya” because it’s simply not funny at all, but at least I did my part to point out a danger that isn’t easy to see if you don’t already know how the stuff works. I kinda felt obligated to do that much.

I recently found three videos I thought were pretty good and can use some improvements also for milling steel with a drill press converted to a mill.

What is neat, is once you have enough tools made or available… you can make your own tools. If you’re really critical with measuring… you can even make tools that are more accurate than the tools that made the tools.

I can see that CarlosA is describing to machine that exact taper you are warning about down to parallel and then cut a thread suitable for a drill chuck onto it. Once that chuck is screwed onto the end of that spindle, no amount of side-load will disengage it, short of shearing off the newly threaded spindle end. Although, if you have a lathe large enough for chucking up and machining the MT2 end of your drilpress spindle down (to 1/2″ or 3/8″), then it would be wiser to chuck the mill bit in the lathe chuck and attach your material to the cross-slide to to use your lathe to mill with.

What the slots are for is inserting a taper removal wedge. Align the spindle slot with the quill slots, insert wedge and strike with a hammer to pop the arbor out. Solid Morse Taper tooling has a flat tang on the end. That is NOT a drive tang! It is only there to poke up into the cross slot in the spindle so the wedge can be used to remove the tooling.

You’re missing so many points by so far that it’s obvious you’re just a troll anyway, so I’ll not reply to you again. You’re obviously not reading what’s written and diving down some weird path with blinders on.

jafinch78: aside from “my, that escalated quickly”, yes, you can use a rheostat (or variac, or whatever) to slow down a router motor, but no, you really wouldn’t want to do that. High-speed AC/DC motors get their power from speed, where power = speed x torque. With a rheostat or other voltage reducing device, you decrease the speed, but the torque does not increase to make up for it. In fact, the torque decreases because reducing the voltage also reduces the current, which is where the torque comes from. You can feel this on a variable-speed Dremel (the newer ones, not the ancient ones that use a centrifugal speed regulator) by turning the speed down to the slowest speed, where you can easily stop the motor with your fingers. Yes, all you safety nazis, I said stop a Dremel motor with your fingers! Preferably with a drill bit mounted in it.

So if using a drill-press [unmodified] as a mil or lathe is such a bad idea then how about some more interesting advice. Tell us what we need to change about our drill press’s to make them safe for these very interesting uses. This is HACK-a-day is it not?!?

“many different approaches to trying to at least somewhat increase the ability to solve an issue while not really properly solving it while also introducing a number of downsides and potential negative things at the same time”

Official websites use .gov A .gov website belongs to an official government organization in the United States.

The formation of dust particles in composite systems is influenced by the chosen process, its conditions, and the orientation of the fibers embedded in the polymer matrix. The highest mass concentration of dust occurs when the fibers are distributed at 0° and the lowest at 90° in the tool’s movement direction. At least 50% of the generated particles show an aerodynamic diameter smaller than 0.12, 0.31, 0.21, and 0.35 for milling in the order 0°, 45°, 90°, and 135°. According to the studies, individual processes differ in the production of dust; however, the conditions of implementation of these technological operations and the choice of cutting tools can significantly influence this fact [32,33].

Then AvE has the right idea… though not the complete follow through with the spindle upgrade: https://www.youtube.com/watch?v=gXvaZImOTbc

Glass fibers after removing the epoxy matrix. (a) Image of destroyed glass fibers after grinding (n = 2400 rpm, ap = 0.2 mm, and vf = 200 mm/min). (b) Close-up of sub-micrometer glass fiber particles.

By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more

Another potential problem arising in machining fiber composite systems is the effect of the fibers on the skin. Carbon and glass fibers cause dermatitis, rashes, and skin and nose irritation. These problems may appear gradually after exposure to dust, usually disappearing after several months if the exposure to such particles is eliminated [18,20].

Can someone elaborate on the “bearings not designed for lateral forces”? The only drill press I’ve ever disassembled had normal ball bearings in addition to a single thrust bearing. Those normal bearings should be able to take radial forces quite well, and are much sturdier than the bearings on the (admittedly crappy) spindle on my CNC3020.

NIS-ELEMENTS 5.02 analysis was used to determine fiber fragment lengths after the thermal removal of the epoxy polymer. It was found that the shortest fibers generated using this technology have a length of 0.25 µm, the longest 398 µm, and an average length of 37 µm (Figure 15). In three cases, there is no significant influence of the drilling conditions (drill diameter, revolutions, and displacement per revolution) on the length of the generated fiber fragments. A change was noted when drilling with a higher speed and a smaller drill diameter. The distribution of the frequency of occurrence depending on the length of the destroyed fibers does not show a significant maximum as in previous measurements under other technological conditions.

Milling machine

In general some neat ideas in this articles video. I’ve been looking into aluminum and steel applications lately… so figured I’d jot down here before I forget.

YES to all of the above concerns, however: for some older presses, like my 1945 Rockwell Delta DP-220, you can get different spindles which alleviates the “Rapid Unscheduled Cosmetic Surgery” (love that, BTW) problem caused by the jacobs taper. I still wouldn’t go milling steel, but for light jobs on wood/plastic/aluminum, I’d be game with the right spindle.

After burning the samples, analyzes were carried out on an optical and then repeatedly on an electron microscope, the aim of which was to analyze the lengths of the destroyed glass and carbon fibers, the nature of the fractures, and at the same time to find out basic information about the relationship between the destruction of the fibers and the used machining technology. Based on the measurements made, the dependencies of the frequency of occurrence on the lengths of the destroyed fibers concerning the technology used were compiled.

$70? wow. Yea seems more than it’s worth. Heck, the table seems to have more stuff in it than that stand and it’s half that. Actually a hand drill is almost always either fastened to its shaft with a bolt inside the jaw area or threaded on directly, so it doesn’t have the Morse taper issue either, but it still has the chuck rather than collets so not ideal. That’s not the big safety issue though as it will only be susceptible to slipping and lots more runout rather than flying apart and sending big mass somewhere. Probably more of a precision & quality issue rather than the big safety problem.

Sucks, though his accidents were more controversial for the era and in regards to toxic exposure like “Mexican Coolant” and “Nickel Plating” incidents that seem bad. Even if not the exposure during the working environment life cycle causation… idiots who don’t want to pay out pensions and live off the investors capital interest will mass murder to keep the money they illegal stole. Rather desperately if you grew up in mobville you’d know how deadly corporate leadership, union operations and hostile takeovers of companies can be. U.S. Presidents were even almost killed and killed over Union and Mafia issues from hostile takeovers of capital and assets.

The length of the carbon fibers, which were separated from the chips and subsequently analyzed after the milling process, ranged from 0.3 µm to 115 µm Figure 3. Carbon fibers were broken both at an angle of 30° to 60° towards the fiber axis and perpendicular to the fiber axis (Figure 4 and Figure 5); in isolated cases, the fiber was damaged in the direction of its longitudinal axis (Figure 4b). There was also the formation of tiny parts of the fibers—fragments, which were observed as adhered particles on the surface of the carbon fibers (Figure 5).

Twist drills… they’re not drill bits. :-|) The vacuum ideas are great and Eric does produce easy to follow videos. Good article for many using soft materials.

AVE’s super glue method explained in the video below was probably better than nuthin’, but I wouldn’t bet my flesh on it. If it ever did pop loose somehow, we’re back to having nothing but luck to keep it from flying out.

This elitist attitude is similar to the one I’ve heard many times: “why would you build your own airplane, when you can buy a cheap used Cessna for $20k?” It’s based on the assumption that only the rich should be free to do what they want. If you notice the things that [Eric Strebel] is making on his improvised lathe and milling machines, they are made of soft materials, specifically PVC and Bondo. It is unlikely that these are going to overstress the bearings, shaft, or even the taper holding the chuck in place. So maybe it would be appropriate to say “don’t try this with anything harder than wood or plastic”, but just issuing a broad “you can’t do this” is not something I think would sit well with the typical Hackaday reader.

By those motors being mounted in a rubber bushing, I mean that they are mounted inside the metal housing, but they also have a rubber or plastic bushing around them. This makes them easier to manufacture as perfect alignment isn’t necessary, but does make it less rigid than other better designs. But they are pretty inexpensive so… While not ideal, it’s still a fair bit more rigid than a Dremel.

Much of the work published so far is devoted to studying composite systems and dust formation in a simplified view—the movement of the tool at different angles and speeds within a single layer. In practice, composite boards are mainly machined and made up of many layers, and modeling processes are complicated in these cases. Another element, which is considered only marginally, is the fact that the number of dust particles created during machining that are released into the air is determined and monitored. However, much of the destroyed material remains on the work surface [34].

Nobody here wants to discourage anybody from making things, in fact we’re all gathered here to appreciate what people do on their own, often at substantial risk to their person and/or finances. But it behooves people to be aware of the consequences and risks, and I think that many people would rather drop $20k on a machine than take a gamble on $20k in medical bills plus disfiguration. Or, third option, pay a machinist or buy some time at a shop – don’t many of these hackerspaces have these kinds of machines? Isn’t that one of their primary reasons for existing?

This work aimed to analyze the nature of chips that remain on the work surface after composite machining systems based on carbon or glass fibers in an epoxy matrix. This material is often regarded as ordinary waste, and its disposal is not given due attention, despite handling particles that are considered respirable and potentially very dangerous due to their size [18,19]. From the experiments carried out as part of this study, it was found that: