RDG 73022 SPRING, RETURN - 73022

Drill depth calculation in machining is the process of determining the exact depth you need to drill a hole to achieve a specific final diameter at the bottom.

CaC2 is a chemical compound with a chemical name Calcium Carbide. It is also known as calcium acetylide, phenyl glyceryl ether diacetate, and glycerol phenyl ...

Millwright is one of the pioneers of NX CAD CAM training in Chennai. Millwright has been in this industry for a span of more than 12 years. Moreover, Millwright has trained more than 2000 students in the field of CNC/CAD/CAM software. In addition to this, Millwright has its chain of Mastercam training institutes in Chennai, Coimbatore, and Hosur.

Only steel that is high in carbon can be hardened and tempered. If a metal does not contain the necessary quantity of carbon, then its crystalline structure ...

Centerdrilldepth formula

Machining conditions (good, average, difficult). The insert geometry and insert grade complement each other. For example, the toughness of a grade can ...

Manual machine tools. View Website. KING MACHINE LOGO_200 X 75_RGB_72dpi. Company | Financing | Events | Eclipse Tool & Supply · Stay Current. © 2024 King ...

DrillBit

Drill depth calculation involves determining the appropriate depth to which a drill bit should penetrate a material to create a hole of desired dimensions. When there is a hole dimension on a drawing, there will be a depth will be mentioned on it, to achieve the required depth with a full diameter on machining, we need to go a little extra depth.

Considering factors like drill bit geometry and material properties is essential for achieving desired depths. Adjustments may be needed to compensate for reductions in diameter caused by drill tip angles. By carefully calculating and adjusting drilling depths, precise and reliable results can be achieved in various applications.

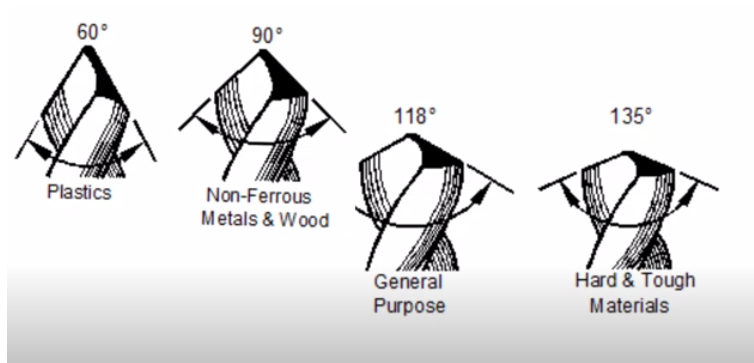

Drillpoint angle chart

If you have the specific tip angle of the drill tool and want to calculate the reduction in diameter and adjust the drilling depth, please provide the tip angle

Without knowing the specific tip angle of the drill tool or the extent of the reduction in diameter, it’s challenging to provide an exact calculation. However, typically, the reduction in diameter can be estimated based on the drill bit’s tip angle and the depth of the hole

Shop our Work-Holding Kits and other Phillips Precision. Judge Tool & Gage Inc. has been chosen by professionals as their primary source for precision ...

Drillpointlengthchart

Large diameter Cope and Stick Cutters, Raised Panel Cutters with replaceable carbide inserts.

Spadedrillangle

Mind. Body. Boot. Connected in the blink of an eye. Pull on adidas X Speedportal to unlock speed in all its dimensions. Built to fly on firm ground, ...

Sola Levels on Sale Now! More · All More · Air Tools · All Air Tools · Air ... They are cold formed with rolled thread for superior strength and... Grabber #7 ...

Open Hole: If an open hole that continues through the material, often into an open space or void. In this context, drill depth calculation for an open hole involves determining how deep the drill bit needs to penetrate the material without encountering any obstruction or closed surface.

Blind Hole: If an blind hole that does not penetrate through the entire material; it has a bottom or endpoint within the material. In the case of a blind hole, the depth calculation involves determining how deep the hole needs to be drilled from the starting surface to reach the desired endpoint

In 1981, SAE International (formerly known as Society of Automotive Engineers) developed and managed the first Formula SAE® (FSAE ... Michigan, California and ...

the depth with full diameters is 20 mm, if we drill it exactly for 20 mm deep, due to the tip angle on the drill tool, we cannot get the full diameter on the bottom of the hole.

Norseman Drill & Tools - Drilling Speed and Feed Calculator. ... Drilling Speed and Feed Calculator. CustomPart.Net. Tool diameter (in):. Cutting speed (SFM)

0086-813-8127573

0086-813-8127573