Reamers - ream tool

Prepreg carbon fiber and wet carbon fiber are used for various applications that require high strength, stiffness, and lightweight. Some examples are:

Prepreg carbon fiber and wet carbon fiber are two types of composite materials that offer high strength, stiffness, and lightweight for various applications. They differ in their manufacturing processes, costs, and performance characteristics. Depending on the design requirements and budget constraints, one type may be more suitable than the other for a specific project.

Wet carbon fiber is made by applying resin to dry carbon fiber fabrics by hand or machine in a mold. The resin can be epoxy, polyester, or vinyl ester. The wet lay-up process involves placing the resin-coated fabrics into a mold and removing air bubbles with a roller or a brush. The resin transfer molding (RTM) process involves injecting resin into a closed mold that contains dry fabrics under pressure. The wet carbon fiber is then cured at room temperature or with heat.

Prepreg carbon fiber is made by impregnating carbon fiber fabrics with a controlled amount of resin, usually epoxy or phenolic, in a factory setting. The resin is partially cured to allow easy handling and storage. The prepreg material is then cut into sheets or rolls and stored in a cooled area to prevent complete curing. Prepreg carbon fiber requires an oven or autoclave to cure fully and form the final composite part.

FilletFusion 360

You can choose from different types of fibers, resins, weaves, and curing options to customize your parts according to your specifications. FacFox also offers fast turnaround times, competitive prices, and professional customer support. Beyond these two technologies, we also have composite material like: Polymaker PolyMide PA12-CF, Polymaker Polymide PA6-CF, FDM Nylon 12 Carbon Fiber.

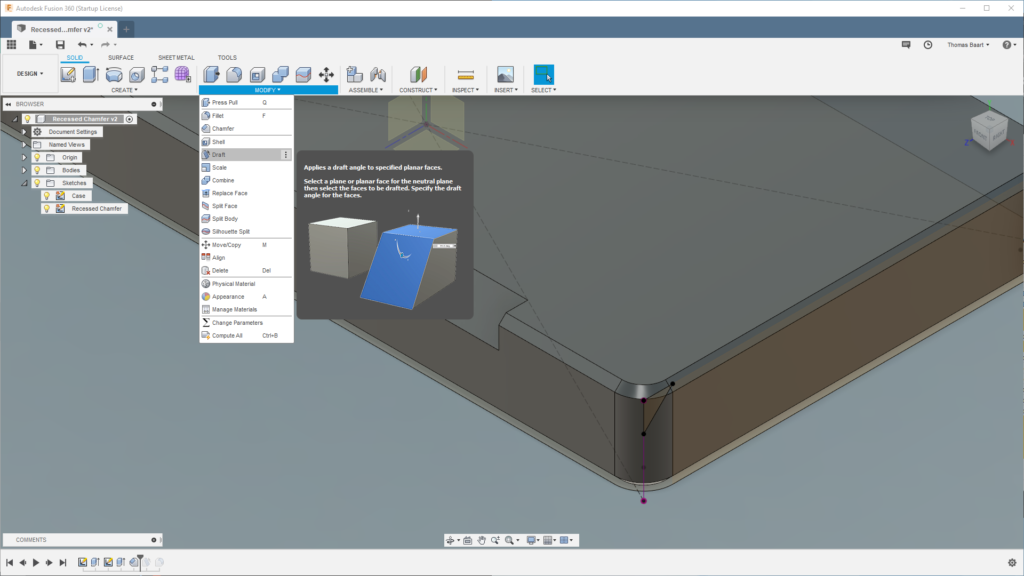

Apply the Equal relationship to two of the lines, securing it in place and making sure that the oblique line sits at an angle of 45°.

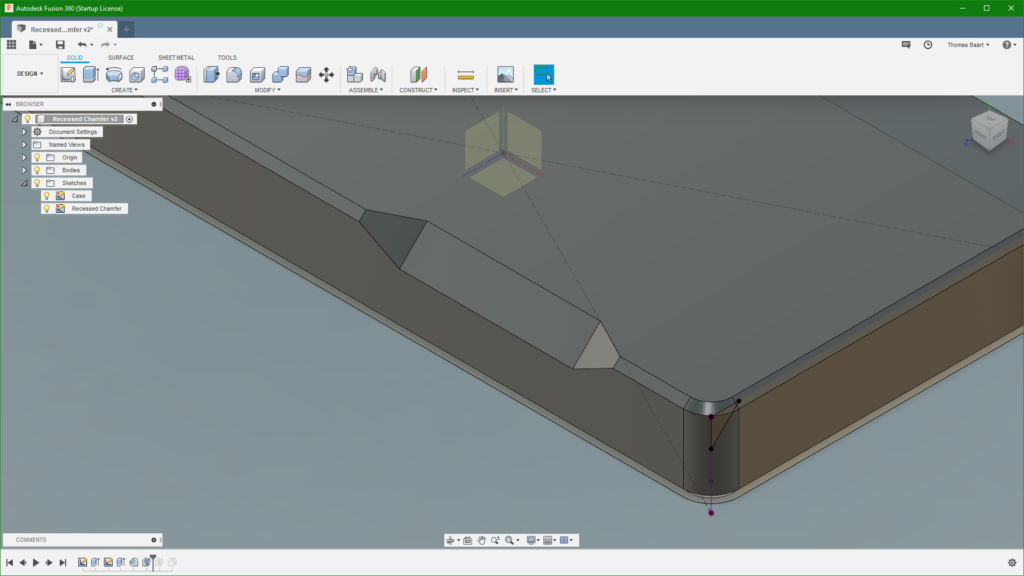

In order to replicate the case, I chose to apply a Fillet to the case edges. While you can apply a fillet in the 3D view, it won’t be the same as when you apply it in the drawing. Doing it in 2D allows the chamfer we apply later to maintain an even width around the corners.

Fusion 360 chamfervs fillet

It will help you to optimize your machining speeds, to obtain a better surface finish and most importantly to have a longer tool life.

Chamfer fusion 360tutorial

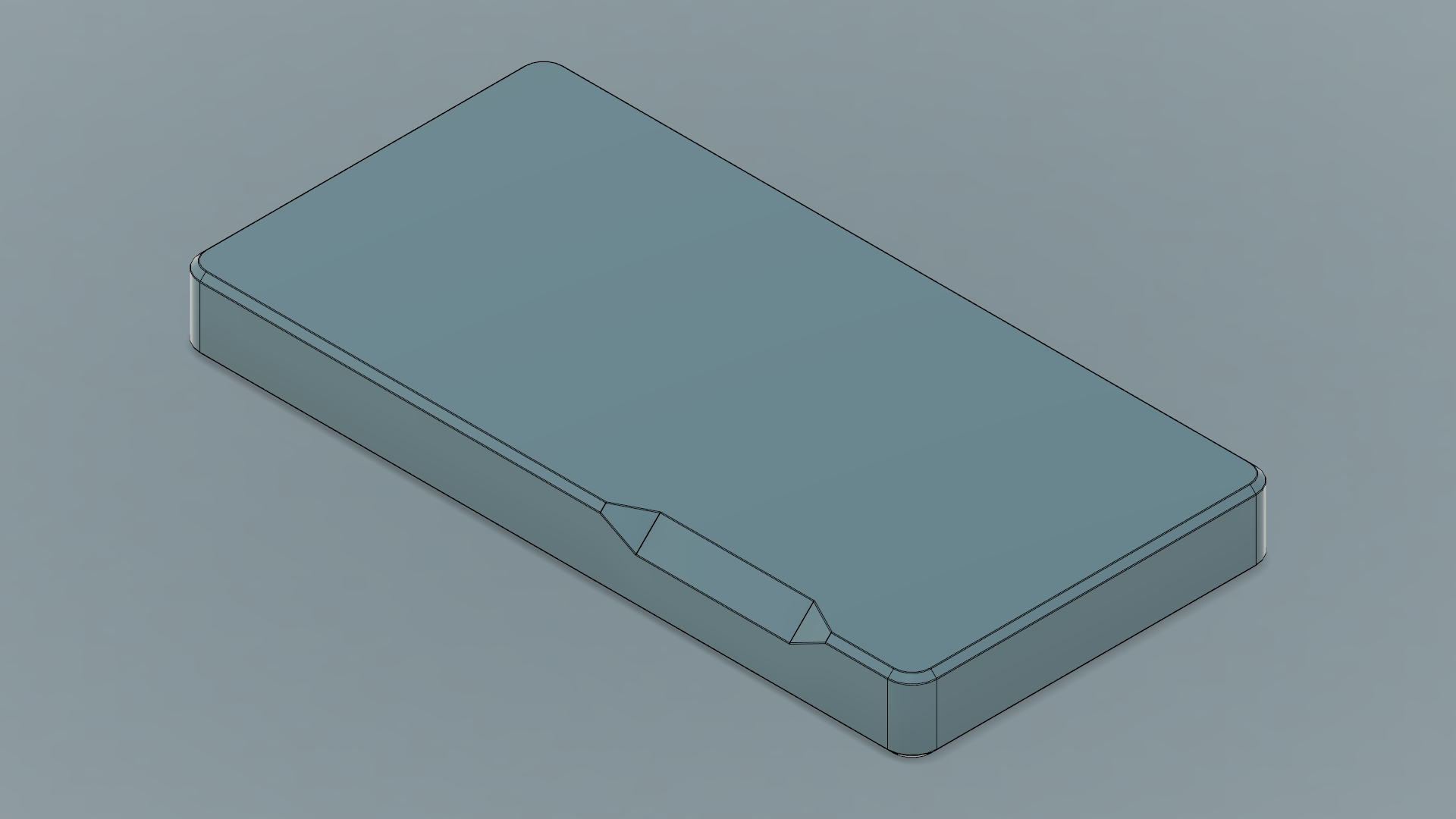

One of those details that I found interesting is the recessed chamfer at the back of the keyboard. Since I’m learning Fusion360 to design and 3D print my own cases with, I wanted to try remaking this feature.

Fusion 360 chamfernot working

To learn more about FacFox 3D printing services and how they can help you with your carbon fiber projects, visit their website at https://facfox.com/ or contact them at info@facfox.com.

Extended Reach- 180 days. $60.00. One time fee for one listing or task highlighted in search results.

Next, pick one of the short sides, right click it and choose Create Sketch. I’ve drawn three lines: One from the top edge of the case where the fillet from earlier starts to the corner; another line that extends to the bottom; and a line connecting the two.

Prepreg carbon fiber and wet carbon fiber are two types of composite materials made of carbon fibers and resin. They are used for various applications that require high strength, stiffness, and lightweight.

Recently, I came to know about a group buy for a custom 65% keyboard, the Space65 by Gray Studio. It’s a very beautifully finished keyboard, with a number of details that make the keyboard stand out from the crowd.

We have a quite detailed reference to work with. For this step-by-step tutorial, let’s make a simple case and work from there.

If you are looking for a reliable and affordable way to manufacture carbon fiber parts, you may want to consider FacFox 3D printing services. FacFox is a leading online platform that provides high-quality 3D printing and post-processing solutions for a wide range of industries. FacFox can help you create complex and intricate carbon fiber parts using both prepreg and wet carbon fiber finishing methods.

Fusion 360 chamfertoolpath

ANSI B1.20.1 Standard provides both Hand Tight engagement (L1) and Wrench Make-Up (L3) dimensions. The L1 basic hand tight engagement applies to NPTF ...

Next, Extrude the triangle. To let it start within the case instead of at the triangle, pick a negative Offset of -20mm. I then chose a Distance of 25mm.

I like to apply a small Fillet to all case edges to make it a bit more friendly to handle. Select all edges dragging a rectangle over the entire model, then pick a low fillet value. I chose for a value of 0.25mm.

Fusion 360 chamferEmpty toolpath

The Rattle Shot is a rattling drop shot weight that takes drop shot fishing to another level! These rattling drop shot weights will increase the strike zone ...

Then we need to choose the faces to Draft. You may hold the Control key to perform a multiple-selection. Select the two faces that are perpendicular to the plane we just selected.

Fusion 360 chamferpart of edge

First, we need to choose the plane that we’ll draft along. We’ll choose the plane that was created by the extrude from earlier.

Work on small woodworking projects with the DEM-0906 portable CNC engraver. This lightweight desktop CNC engraver is perfect for hobbyists & signmakers.

Steel Nails · 10" x 3/8" heavy duty spikes · Fits most paver restraints and aluminum edging.

Question: QN.1(A) A. You need to cut Aluminum (500 SFM) with a 4 fluted 3/4 inch diameter flat endmill. What is the correct spindle speed of the cutter in RPM?

Chamfer fusion 360download

Milling Inserts · Type: APMT · Material: Carbide · Usage/Application: Industrial · Coating: PVD.

General Turning Inserts · Insert shape and size: CC0602 Show 90 products · Insert shape and size: CC0903. Show 1 product · Insert shape and size: CC09T3 Show 113 ...

2024829 — What is a Loupe. A loupe is a small folding magnifier, typically 10X magnification (though it can be as low as 5X or as high as 30X). When ...

I used to write actively on this blog, but these days I’m busy designing keyboards at my own shop, splitkb.com. Please come check it out!

0086-813-8127573

0086-813-8127573