Replacement Drills - square drills

Choosing between a Corner Rounding End Mill and a Back Corner tool boils down to the location on the part you’re machining. A Back Corner Rounding End Mill should be utilized to put a radius on an area of the part facing the opposite direction as the spindle. While the material could be rotated, and a front Corner Rounding End Mill used, this adds to unnecessary time spent and increased cycle times. When using a Back Corner Rounding End Mill, ensure that you have proper clearance for the head diameter, and that the right reach length is used. If there is not enough clearance, the workpiece will need to be adjusted.

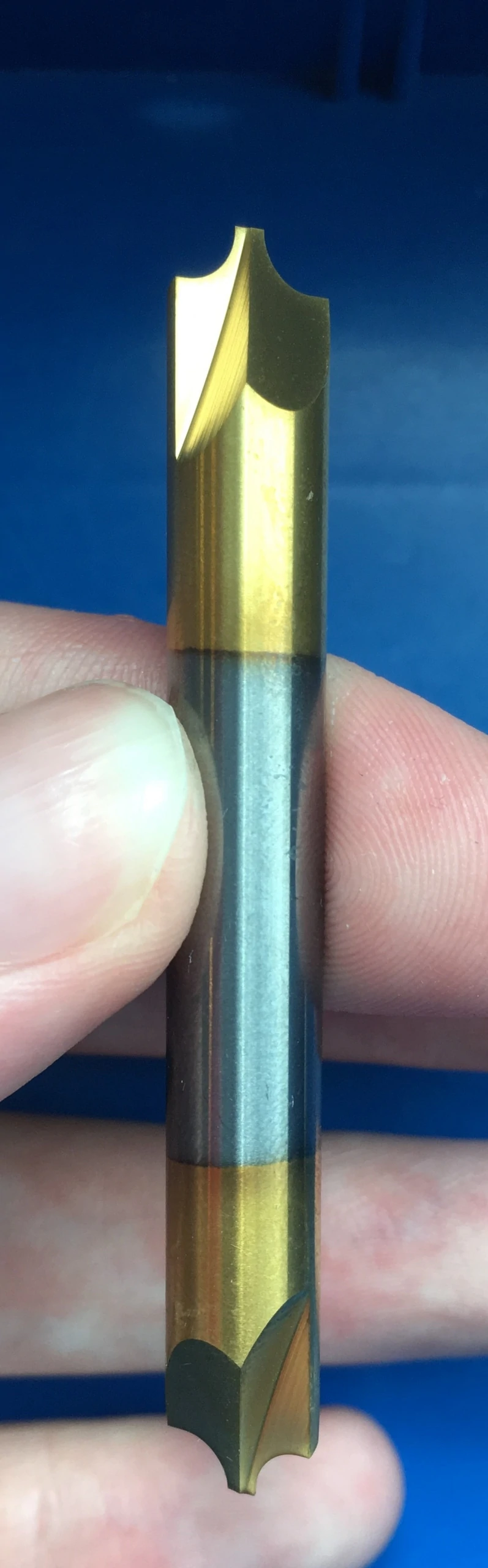

These tools are often offered in 2, 3, and 4 flute styles. 2 flute styles are normally used for aluminum and non-ferrous materials, although 3 flutes is quickly becoming a more popular choice for these materials, as they are softer than steels so a larger chip can be taken without an impact on tool life. 4 flutes should be chosen when machining steels to extend tool life by spreading out the wear over multiple teeth. 4 flute versions can also be run at higher feeds compared to 2 or 3 flute tools.

Corner roundingend mill feeds and speeds

At the moment, I’m leaning towards using calc, but I’m still figuring out the best practices here. In the meantime, understanding this math will help me add a little bit more polish to interfaces with rounded corners.

China Carbide Cold Heading Dies, Blank Yg20c Tungsten Carbide Cold Heading Dies for Hardware Parts Stampings,Tungsten Carbide Cold Extrusion Dies for ...

Steel Supply, L.P. ships T304 Stainless Flats 12 feet long via LTL freight. The best online source of Stainless Flat Bar shipped directly to your business.

We solve complex responsive web design and development challenges for ecommerce, healthcare, fashion, B2B, SaaS, and nonprofit organizations.

The global textile recycling market size is projected to grow from $6.08 billion in 2024 to $8.49 billion by 2032, at a CAGR of 4.3% during the forecast ...

CarbideCorner RoundingEnd Mill

Burchett Quality Tool, Ltd. 5271 Wynn Rd. Kalamazoo, MI 49048. Call Today: (269) 344-3041.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

I was recently designing an interface with a lot of rounded corners. I wanted to make sure the corners were consistent, so I created a --border-radius custom property and went wild rounding those corners.

But, I quickly ran into a problem. When I nested an element with a rounded corner inside of a rounded container it looked off somehow:

Corner roundingimage

Putting a full radius on a part has the potential to leave a step or an over-cut on a workpiece. This can happen if the tool isn’t completely dialed in or if there is minor runout or vibration. A slight 5° flare on the pilot and shoulder blends the radius smoothly on the workpiece and avoids leaving an over-cut.

Stay ahead of the curve! Subscribe to our newsletter and unlock a treasure trove of insights and tips to make your web site better.

Here is how I went about setting out and cutting my dovetails using hand tools and with some practice you can too.

In this article, I'll go over some of these methods, the pros and cons, and how to pull them off successfully.

Corner RoundingEnd mill sizes

1 Features · 2 Types. 2.1 End mill; 2.2 Roughing end mill; 2.3 Ball cutter; 2.4 Slab mill; 2.5 Side-and-face cutter · 3 Usage. 3.1 Chip formation; 3.2 ...

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

The difference between the two circles’ radii is the gap between the outer circle and the inner circle. We can apply this same logic to determine the correct value for our rounded corners.

The best corner rounding end mill varies from job-to-job. Generally speaking, opting for a tool with the largest pilot diameter possible is your best bet, as it has the most strength and requires less power due to its larger effective cutter diameter. A flared Corner Rounder is preferred for blending purposes if the workpiece is allowed to have an incomplete radius as this allows more forgiveness and can save on set up time. If not, however, an unflared Corner Rounder should be utilized. As is often the case, choosing between number of flutes boils down to user preference, largely. Softer materials usually require fewer flutes. As material gets harder, the number of flutes on your tool should increase. print

We solve complex responsive web design and development challenges for ecommerce, healthcare, fashion, B2B, SaaS, and nonprofit organizations.

Paul Hebert is a hybrid designer and developer at Cloud Four. When he's not designing and developing websites he enjoys bouldering, drawing, cooking, gardening, and eating too much cheese.

Corner Roundingcutter

I’m not sure what this means yet when it comes to managing border-radius tokens in design systems. Should we be storing multiple border-radius tokens (inner and outer)? Or does it make more sense to store one primary radius token, and dynamically calculate the rest using calc?

IndexableCorner RoundingEnd Mill

A flared Corner Rounding End Mill leaves an incomplete radius but allows for more forgiveness. Additionally, this tool leaves a clean surface finish and does not require a second finishing operation to clean leftover marks. An unflared corner radius leaves a complete radius on the workpiece, but requires more set-up time to make sure there is no step.

Eventbrite - Terra Nova presents END OF REACH - Friday, March 29, 2024 at 2111 Main St #113, Vancouver, BC. Find event and ticket information.

Find many great new & used options and get the best deals for Aviation Tool Catalog Aircraft Tool Supply Company Oscoda Michigan at the best online prices ...

Corner roundingangle

To fix this, I had to take a step back and think through how CSS border-radius actually works. It can be helpful to imagine each corner holding a little circle. What border-radius is actually doing is setting the radius of these tiny circles.

It is always fun when reading about CNC machines as this teaches me so much more. I really didn’t know Corner Rounding End Mill Decisions existed know I will have to study about it in detail. Thanks to the writer, great article.

Unique convenience and durability. Different cutting shapes available. To be fitted with any electric drill or powerdrill with 3000RPM. 360 ° rotatable cutting ...

Larger pilot diameters also have more strength than smaller pilot diameters due to the added material behind the radius. A smaller pilot may be necessary for clearance when working in narrow slots or holes. Smaller pilots also allow for tighter turns when machining an inside corner.

I’m not Cloud Four’s resident circle expert, but thinking about rounded corners as circles helped me understand the math behind nesting rounded corners. To nest one circle inside of another, the inner circle needs a smaller radius than the outer circle.

Corner RoundingEnd Mill

They work extremely well in Titanium. We suggest using our 4 flute Corner Rounder with our AlTiN coating in the desired radius you need.

A Corner Rounding End Mill is typically used to add a specific radius to a workpiece, or in a finishing operation to remove a sharp edge or burr. Prior to selecting your tool, mull the following considerations over. Choosing the right tool will result in a strong tool with a long usable life, and the desired dimensional qualities on your part. Choosing wrong could result in part inaccuracies and a subpar experience.

The pilot diameter (D1 in the image above) determines the tool’s limitations. When pilot diameters are larger, the tool is able to be run at lower speeds. But with smaller pilot diameters, the tool can be run faster because of its larger effective cutter radius. The effective cutter diameter is determined by the following equations depending on the radius to pilot ratio:

0086-813-8127573

0086-813-8127573