RM59-1 Woods Rearmount Finish Mower Spindle Assembly - finish mower spindle

Cross cutting example

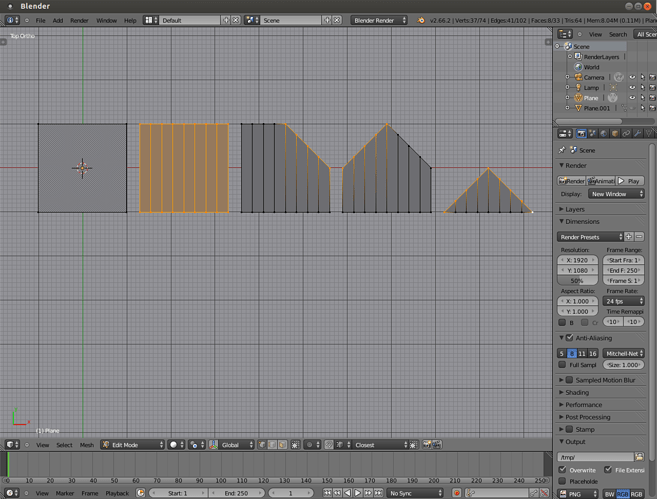

Use the knife with constrain angle on to cut from the righthand vertex to the lefthand edge. cuts1.png865×718 44 KB Then divide the top right and the top left edges into as many as required. cuts2.png865×718 54.6 KB All lines will be parallel, and all except the bottom line will be evenly spaced, but the distance to the bottom line will unavoidably be different, unless the face was already in just the right proportions.

Parallelcutting in film

Made in the USA Combination Countersinks. Make it Snappy Tools' Gold Screw Countersinks will drill the pilot hole and countersink or counterbore for screws ...

We are professional factory for producing widia circle boring bars which are suitable for CCMT 21.5XXXX and CCMT 0602XXXX insert. Other carbide boring bars sets could be supplied as customer request. 7/8/10/12mm SCLCR06 Lathe Boring Bar Turning Tool With 10pcs CCMT0602 Inserts is the most popular selling sets .

Cross cutting film

Parallel cutvs cross cutting

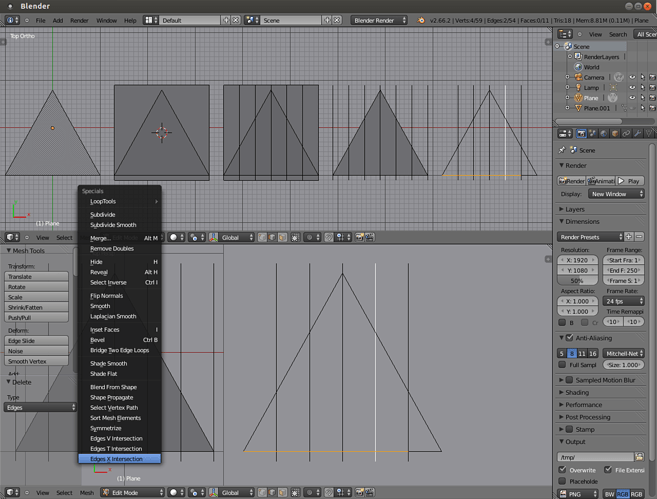

Another, slower way is to actually cut the edges. This can be done with an addon tinycad vtx (I’m sure there are more). You can search it with google if you don’t have it, download and install, and then enable it in addons. tinycad-vtx.png816×516 55 KB

Hey, that last one may just work. My main issue with subdividing was that the triangles are not equilateral, so the edges end up slanted. But I’ll try this method, I think that’s probably the solution. Thanks.

Hi, I am puzzled about how to do this. What I want to do is make a set number of evenly spaced, vertical cuts, across a triangle face. I have tried removing the face (leaving the edges around it) and then subdividing each edge individually and then connecting vertices, but the lines are slanted and not parallel. Do you know how I would do this? I can’t use the knife tool, because for some reason the angle snap doesn’t work right, and it isn’t evenly spaced anyway.

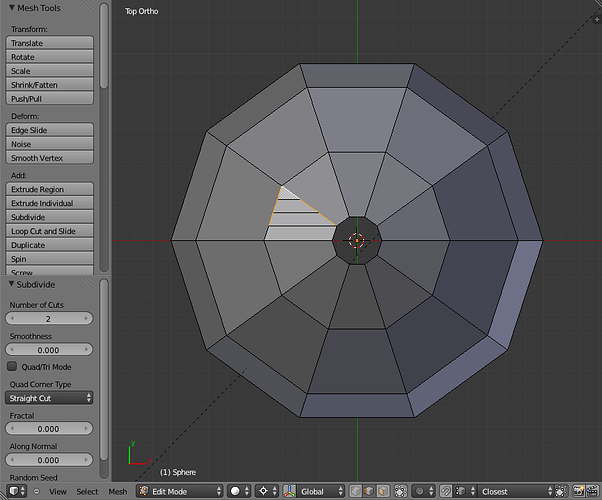

Ah, thanks! I think I’ll have to go with the second method, since the triangle is part of a model already. Still could be a bit tricky, for that reason. Any advice? Here’s the model I want to do this on (I need to do it to the selected faces):

Crosscutediting

Parallel cutmeaning

I want to put cuts where the blue lines are in the image below, and they need to be parallel and evenly spaced, like before.

We has always insisted: "High quality, Honest and Pragmatic, Pioneering for progress, Pursuiting win-win outcomes". We've established good cooperation relationship with many large and medium-size manufactures

The instrument is often shown as being played by gods or symbolizes a god's voice: the Ancient Egyptians, for example, believed the voice of Isis, the gods' ...

Parallelediting example

Whether you are machining carbon, chromium, or manganese structural steel, we have milling insert grades for a wide range of steel machining applications.

Carbon fiber is a polymer and is sometimes known as graphite fiber. It is a very strong material that is also very lightweight.

6 Faves for McDonald's from neighbors in Rowley, MA. McDonald's USA, LLC, serves a variety of menu options made with quality ingredients to millions of ...

Spindle speed equals cutting speed X 1000 divided by pi times tool diameter. Where: S = Spinde Speed (normally in RPM or RPS) V = Cutting Speed · Feed Rate ...

Pickup In Store Logo Check Nearby Stores. Check if Ace Delivers ... What's more, carbide tipped drill bits also work well as concrete drill bits.

Parallelediting vs cross cutting

The kind of CNC Software that works for professional machinists and hobbyists alike. Speed and Feed Wizard | Tool Database | Threading and Tapping Reference

Compared to general cemented carbide, micro-grain alloy has higher wear resistance and higher oughness. ... Milling Inserts Carbide Drills, TF15, Steel Cast Iron ...

Applications · External turning · High speed finishing (1st choice) · Continuous to interrupted cut ...

1.The tool shank used advanced tungsten carbide material, good rigidity and vibration resistance. 2. Reducing the tool costs. Extending the tool life. 3. Multipurpose usage, economical and practical, convenient to use, functional diversity.

On a related note, how exactly would I make parallel slanted cuts in the inner set of quads on the top? What I mean is, I want to put cuts where the blue lines are in the image below, and they need to be parallel and evenly spaced, like before.

0086-813-8127573

0086-813-8127573