ROK 2 PC Polishing Bonnet 10" - 53050 - 53050

Faculty or Professional Staff Member: "I'm a fast learner and comfortable with technology. Because most of our interactions used to be in-person, and COVID-19 made in-person interactions impossible, I quickly became the team's resident virtual meeting expert. This allowed me to create a more engaging virtual environment for our team interactions, and I also taught my teammates some of the finer points of the Zoom platform, so they were also able to hold more successful virtual meetings."

Dean, Department Head or Manager: "I agree that your ability to quickly learn an unfamiliar tool and implement it on behalf of our team was incredibly valuable during this challenging time. I would add that your ability to patiently and effectively share your new learning with your colleagues was an equally important accomplishment — one that created far-reaching success among your colleagues. This also shows how adaptable you are."

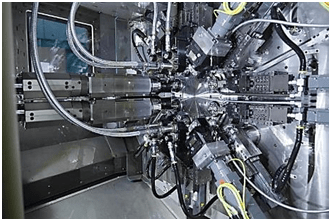

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

Performancereviewstrengthsand weaknesses examples

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

self-appraisal comments by employee example

Faculty Administrator: "I have experience working with large groups of academics. For example, a few years ago I served as Chair of the Program Committee for the national conference for my professional association. I developed the capacity to lead large meetings and resolve differences amongst the members of the Program Committee. I have been able draw on these skill as Department Chair/Associate Dean."

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Performance strengthsexamples

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Performance strengthsand weaknesses

Review the goals you set earlier in the year. If you were able to accomplish them, use them as a jumping-off point. Share how you accomplished the goal, and what you do well that allowed you to do so.

Deans, department heads and managers can also use these tips to describe accomplishments and strengths in their section of the review.

Performance strengthsfor employees

Dean/Supervisor: "I am glad to hear that you have been able to draw on those leadership experiences from faculty life and bring them to bear in your current role. I agree that those are important skill and encourage you to continue to develop your capacity in this area. Helping your colleagues learn how to work well together is equally important."

5 keystrengthsof an employee

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

For a better experience, click the icon above to turn off Compatibility Mode, which is only for viewing older websites.

Top 10strengthsof an employee

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

self-evaluationstrengthsand weaknesses examples

Describing the accomplishments and strengths demonstrated by faculty members in their administrative roles and professional staff is essential to development conversations, and in turn, development plans that result in engagement and excellence.

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

Identify something you accomplished that wasn't an established goal or objective. Maybe you learned something new and put it into practice, or helped your program, department, school/college or team work through an unforeseen challenge. Remember to share what you do well that helped you with the accomplishment.

A strength is "the ability to consistently provide near-perfect performance in a specific activity." –Gallup, "How Employees' Strengths Makes Your Company Stronger"

Starting in 2024, faculty members with administrative responsibilities – assistant and associate deans, assistant and associate department heads and program directors – will complete a separate review focused on their administrative roles.

The list of strengths below are examples that may be used to to detail accomplishments within the Performance Development Process.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

0086-813-8127573

0086-813-8127573