ROLEX DATEJUST 16030 - 16030

PCDend mills for aluminum

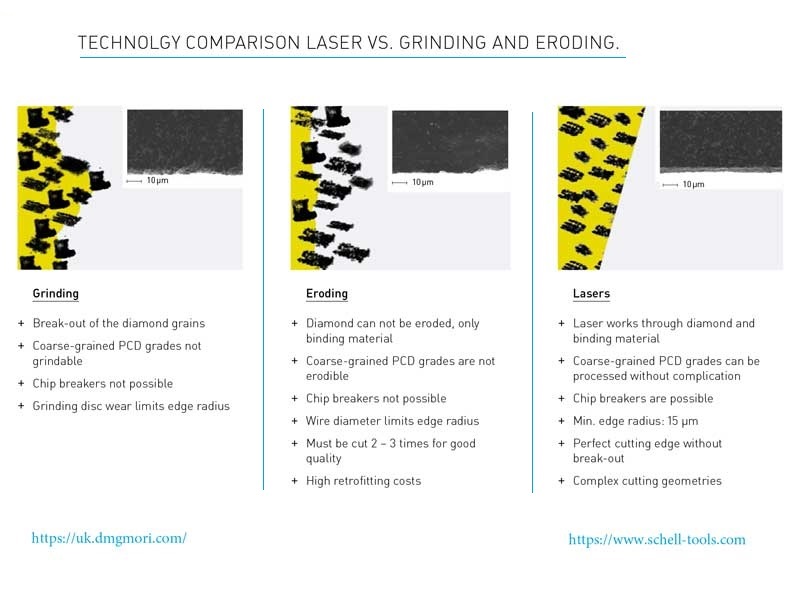

The PCD cutting edges of the DIASTAR PCD milling cutter are laser-machined on a Lasertec 20 from DMG Mori. The PCD laser cutting of the PCD milling cutters offers unique advantages over grinding and wire eroding: In contrast to grinding and eroding, the laser cuts through both the PCD and the binding material, with the advantages:

Harvey toolPCD

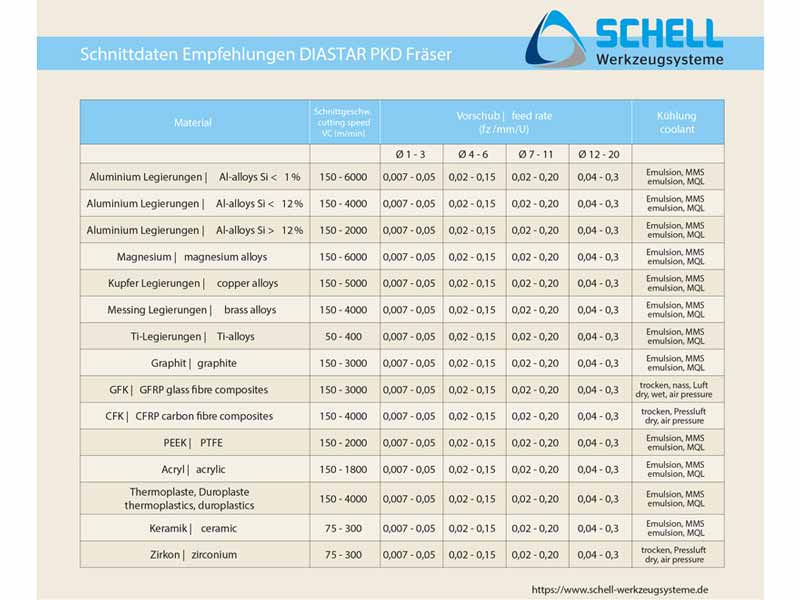

Non-ferrous metals such as aluminum can be machined with the DIASTAR PCD End Mills without cooling and still achieve excellent tool life and surface finish. PKD torus milling cutters achieve up to 50 times longer tool life compared to carbide cutters. DIASTAR PCD milling cutters are ideal for milling graphite, aluminum alloys, copper, brass, bronze, zinc, magnesium alloys, (pre) sintered carbide, rubber, carbon as well as carbon and glass fiber reinforced materials (GRP, CFRP, aramid ).

PCDBall end mill

DIASTAR torus end mills are available from stock as semi-standard. Corner radii are then attached at short notice as desired.

For the processing of honeycomb composites, fiber plastics, sandwich materials, foams, graphites, aramid fibers as well as for woodworking, we also recommend the use of SCHELL diamond-coated CARBONSTAR end mills.

On the solid carbide shank of the DIASTAR PCD milling cutters from SCHELL cutting inserts made of polycrystalline diamond (PCD) are applied with center cut. PCD consists of many single crystals, which are sintered at very high temperature and high pressure. The polycrystalline diamond has a very fine-grained structure, is extremely hard and hardly wears out. The hardness of PCD is almost equivalent to monocrystalline diamond and has excellent mechanical wear resistance and high thermal conductivity during milling.

0086-813-8127573

0086-813-8127573