Round Bottom Tapered Neck Cups - tapered neck

Whydrill bit angleis118

A corner radius is the curved part of an edge that links the straight edges together. These corners may be long and gradual or short and tight. It may not be possible to bend some rubber profiles around very tight corners. This help guide provides two methods to determine the size of your radius so that you can decide whether our seals will be suitable.

For example, if your plate, glass or other item measures 150mm diameter, your corner radius will be 75mm (half of 150mm).

118 vs 135 drill bit anglefor steel

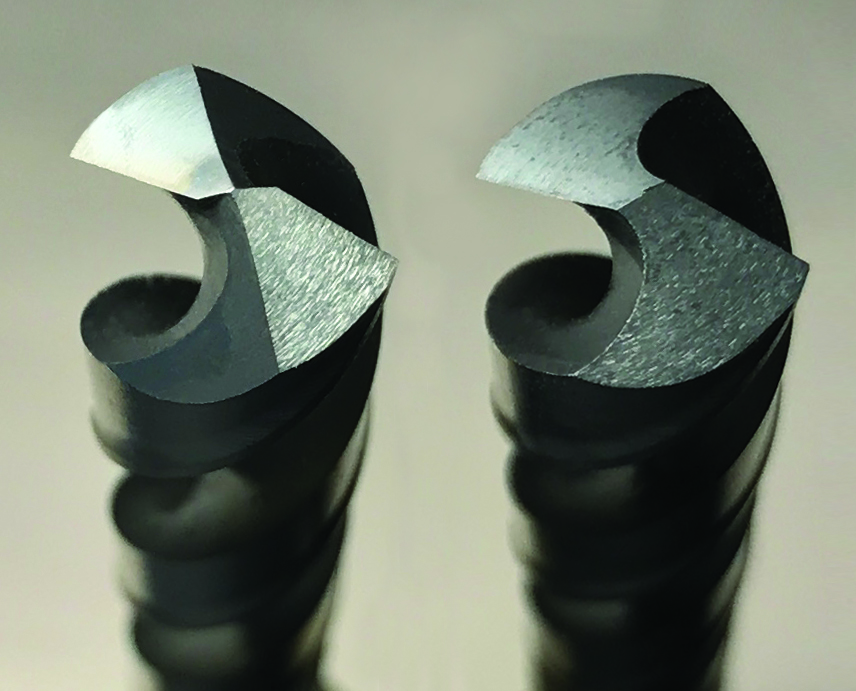

The two most common drill point styles are 135° split point and 118°. As you can see from the picture, the 135° has four cutting edges while the 118° has two.

118 vs 135 drill bit anglefor metal

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Bend radius diagrams for a number of our clip on edge trims, window seals and rubber extrusions can be found in the bottom right hand corner of the product drawing on each product page. Depending on the type of profile, seals often bend differently in different ways. These figures indicate the minimum radius that the seal can be bent for each origination whilst still allowing it to fit correctly without affecting the sealing face.

T: +44 1425 617722 E: sales@sealsplusdirect.co.uk

118 vs 135 drill bit anglemetric

118 vs 135 drill bit anglereddit

Atlantic Fasteners Co., a certified master distributor of pipes and fittings, fasteners, anchors, shoulder screws, bolts, cutting tools, cleaners, and other hardware. Serving the commercial, military, aerospace, construction, and industrial markets. Providing reliable, quality products, 24/7 emergency services and local expertise.

Another way of measuring the radius of the corner is to place a circular item (such as a plate, glass, tape reel etc) in the corner. It is important that you choose the correct size item to ensure you obtain an accurate measurement of your corner radius. The item needs to fit perfectly into the corner so that the curve of the item matches the curve of the corner. This may involve trying several circular items until you find one which is a good size.

Unit 6, Milton Business Centre Wick Drive , New Milton Hampshire BH25 6RH , United Kingdom

One way to measure the corner radius is to draw two lines where the curve starts to straighten (as shown in the diagram). You can then measure the distance from the point where the two lines intersect to any part of the radius (ie, the curve of the corner).

Once you have found an item that fits your corner, measure the diameter of the item as shown in the diagram. After you have taken this measurement, you can obtain the corner radius by dividing your measurement by 2.

118 vs 135 drill bit anglefor woodworking

“One is good for soft material, another for hard. One typically requires center punching, the other doesn’t,” he continues.

"Maintenance people and buyers alike find drill point styles confusing,” says Atlantic’s Customer Service Manager, Tony Orvis, who’s been in the fastener business for 26 years.

So Orvis says he approached Atlantic’s technical and marketing departments to create a simple comparison piece on the two most popular drill point styles, 135° split point and 118°. His chief request was for a sharp picture of each tip, so the differences are readily apparent.

Whilst these diagrams provide the minimum recommended bend radius, it is sometimes possible to adapt the seal so that it can be used around tighter corners. One option is the cut and mitre the profile by cutting small triangles out of the inside to reduce buckling as it is bent. With clip on edge trims it is also possible to insert a small piece of expanded neoprene cord inside the sponge sealing bulb. This will help reduce the bulb from compressing.

0086-813-8127573

0086-813-8127573