Roundover Router Bit Set (4-Piece) - 1 4 round router bit

Rolling-in entry reduces vibration and enhances tool life, allowing for a gradual engagement with the workpiece that optimizes overall cutting performance.

We partner with market-leading international law firms, financial institutions and corporates, guiding them through each stage of their recruitment processes.

Who ownsharvey partners

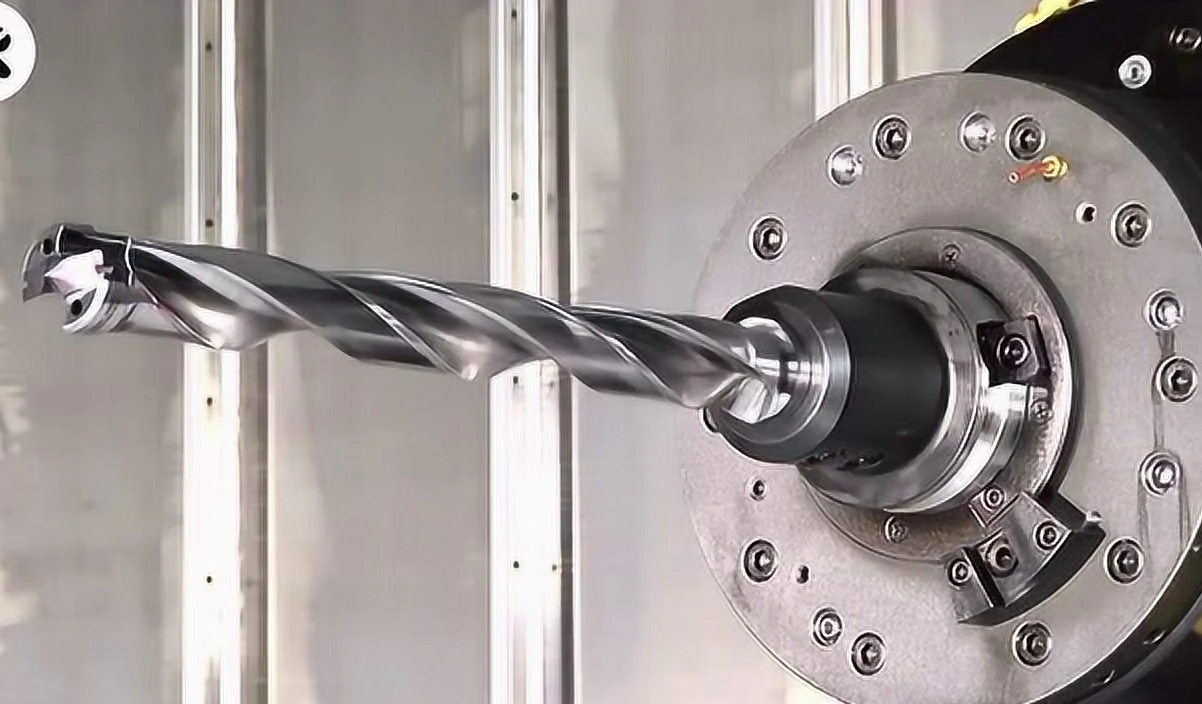

In CNC machining, peripheral milling is distinct from end milling, where the cutting edge is on the outer arc of the tool. Peripheral milling leverages the tool’s full advantage, such as maximum cutting speed, stable cutting force, and lower cutter shaft deformation. When changing the tool inclination, the working surface of the tool can better match the surface of the machined parts and adapt to its curvature changes.

“Charlie is an excellent legal recruiter and a pleasure to work with… I would highly recommend him to any candidate looking for a senior position or a law firm looking for a legal recruiter to partner with.”

BOYI provides expert CNC machining and injection molding services in China, delivering quality parts quickly and efficiently from prototyping to production.

Due to these advantages, peripheral milling is commonly used in a variety of industries, including aerospace, automotive, and medical device manufacturing. It is particularly suited for applications requiring high precision and complex shapes, such as the production of gears, turbines, and implants.

“Charlie has a great knowledge of the industry and has provided some fantastic advice and support to me when navigating interviews and negotiations! Thanks Charlie.”

Peripheral milling, also known as cylindrical milling, is a fundamental process in computer numerical control (CNC) machining. It involves the use of a cylindrical milling cutter to remove material from a workpiece. The cutting edge of a peripheral milling tool is located on the circumference of the tool, making it suitable for specific applications where high thickness and hardness materials, particularly curved surfaces with large curvature changes, need to be machined.

There are two main types of peripheral milling: conventional (Up Milling) and climb milling (Down Milling). Conventional milling involves the cutter rotating against the direction of the feed, while climb milling has the cutter moving in the same direction as the feed. Each type has its own applications and advantages depending on the specific machining requirements.

Harvey partnersnet worth

The method of workpiece entry is vital for performance. Rolling into the cut minimizes shock and wear on tools, promoting smoother operations and extending tool longevity.

At Harvey and Partners, our experience as corporate and finance lawyers at leading international law firms gives us unparalleled insight into what makes exceptional lawyers, and law firms, tick.

Peripheral milling is a versatile and powerful technique in CNC machining. By understanding its principles, advantages, and challenges, manufacturers can harness its full potential to produce high-quality components efficiently. With the right tool selection and optimization, peripheral milling can be a key driver of productivity and innovation in modern manufacturing.

Harvey partnerstarrytown ny

“Charlie’s reputation and various awards precede him, and having worked with him it’s easy to see why… [he brought] us exclusively great candidates, resulting in an excellent hire.”

FountainheadPartners

“[We] especially valued Charlie's counsel throughout and his authenticity and desire to create a positive long lasting relationship continues.”

“Charlie was extremely well-informed with regard to my move… I appreciated the way he applied no pressure and the fact he came from private practice (Slaughter and May) himself ensured he fully understood my situation and my experience.”

“Charlie is comprehensive in his approach and extremely discerning, so we can be completely confident that he understands our business and will only ever submit excellent candidates.”

Harvey PartnersAUM

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.

“… one of the ‘go to’ headhunters for senior moves in London. Thoughtful, considered and professional but also highly effective.”

A robust cutting force model aids in predicting performance outcomes, facilitating optimal selections for feed rates and cutting depths. This modeling is essential for maintaining consistent machining quality.

Harvey partnerslinkedin

This ratio is crucial for optimizing tool wear and enhancing material removal efficiency. Proper management of this ratio leads to improved machining performance and longer tool life.

While both techniques are used for surface finishing, face milling employs a cutter that rotates perpendicular to the workpiece, ideal for flat surfaces. In contrast, peripheral milling uses cutting edges aligned parallel to the workpiece surface, making it effective for detailed and complex features.

“[Charlie] spent time getting to know me and my drivers and the whole process felt focused and efficient with him managing it. I would firmly recommend Charlie to my own network.”

“Charlie … works extremely hard for his clients. [His] help at every stage is invaluable and he makes the process seamless.”

We partner with exceptional lawyers - both in private practice and in-house - advising them throughout the full life cycle of their careers.

To overcome these challenges, manufacturers often invest in high-quality tooling, advanced fixture designs, and state-of-the-art CAM software. Additionally, regular machine maintenance and operator training are essential to ensure optimal process performance.

0086-813-8127573

0086-813-8127573