Roundover Router Bits - 3/4 inch round over router bit

Use the shortest drill possible as shorter drill bits are more accurate and because they’re more rigid they don’t break as often, Shorter drill bits are also better in confined spaces.

1 - Machining profile and attachment angle · 2 - Insert geometry · 3 - Size of the insert · 4 - Corner radius insert · 5 - Substrate quality and coating.

201471 — The following equation is used to calculate spindle speed: rpm = sfm ÷ diameter × 3.82, where diameter is the cutting tool diameter or the part ...

- When drilling using Hand held Drill machines, Rpm may need to be reduced as feeds are being applied manually. This may help prevent excessive wear and work hardening of materials.

Drill bit lengths explained

2022127 — how to identify your turning insert · Making sense of the ANSI (American National Standards Institute) insert code system · Insert Shape (CNMG332).

- For hard to machine materials, interrupted cutting or unstable setups a reduction of feeds and speed of 50% may be required.

Jobberdrill vs twist drill

“One is good for soft material, another for hard. One typically requires center punching, the other doesn’t,” he continues.

JobberDrill bit size chart

Many machinists utilize centre drills for spotting instead of real spotting drills. Center drills are designed to provide a hole suitable for a lathe centre.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Browse categories: Lathe Chucks, Power Chucks and Hydraulic Cylinders, Magnetic Chucks, Machine and Bench Vises, Milling Fixtures, VDI Toolholders.

Mechanicslengthdrill bits vsjobber

I bought this ancient Armstrong cut-off tool holder. It has been a godsend. Zero chatter. Zero binding, etc. Even cutting 304 with auto-feed.

Drill bitlengthChart

What is ajobberdrill bit used for

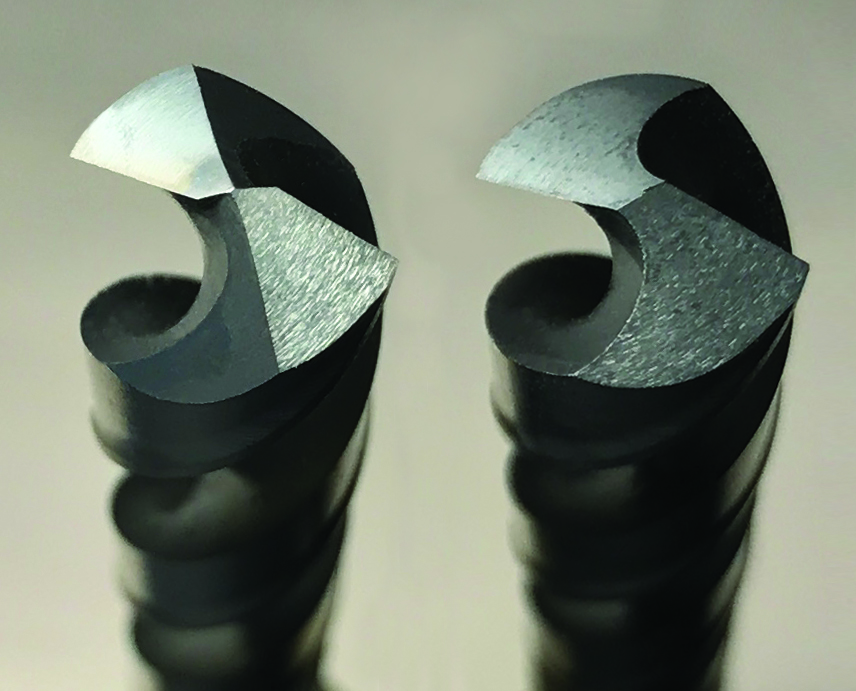

So Orvis says he approached Atlantic’s technical and marketing departments to create a simple comparison piece on the two most popular drill point styles, 135° split point and 118°. His chief request was for a sharp picture of each tip, so the differences are readily apparent.

Carbide Turning Inserts- Screw-On Style Turning Insert. - Used for semi-finishing and finishing on a wide range of materials.

The two most common drill point styles are 135° split point and 118°. As you can see from the picture, the 135° has four cutting edges while the 118° has two.

JobberDrill Bit Set

Reduced Shank: 5XD (However, usually share a common length of roughly 6" (152mm) overall length with a 3-3/8" (86mm) flute length)

118º Standard is found on most common drill types. 135º Self-centering (split point) enables faster starting and cutting actions, especially in hard steels and stainless steel.

For example: Jobber drill length drills are 5xD, this means a 5mm jobber drill would have an effective drilling depth of 25mm.

Dills are often described by their length, referring to the effective flute length or maximum drilling depth in relation to the diameter.

Atlantic Fasteners Co., a certified master distributor of pipes and fittings, fasteners, anchors, shoulder screws, bolts, cutting tools, cleaners, and other hardware. Serving the commercial, military, aerospace, construction, and industrial markets. Providing reliable, quality products, 24/7 emergency services and local expertise.

Parabolic Design (often called deep hole jobbers) – usually 40° Helix angles, the open design helps chip removal out of the hole. These are especially effective in very soft materials like plastics and aluminium’s.

Calculation are as follows: Chip Load = Feed Rate (inches per minute) / (RPM x number of flutes). Example: Chip Load = 500 inches per minutes / (15,000 RPM x 2 ...

Jobberdrill bitlength

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications.

CVE-2022-43447 Detail · Description · Metrics · References to Advisories, Solutions, and Tools · Weakness Enumeration · Known Affected Software Configurations ...

"Maintenance people and buyers alike find drill point styles confusing,” says Atlantic’s Customer Service Manager, Tony Orvis, who’s been in the fastener business for 26 years.

0086-813-8127573

0086-813-8127573