ROUTER BIT CHAMFER 30 DEG 1/2" SHANK (FRE-40-206) - 30 degree chamfer router bit

In 2025, Miller’s group is set to expand both in terms of graduate students and LCA projects. Next on the list is the G-Beam bridge girder, which features a FRP lamina composed of glass, carbon fiber, foam core, and resin, making it lightweight and easy to transport.

Oct 3, 2014 — I prefer HSS for interrupted cuts and better surface finish while I use Carbide for heavier cuts when needed.

Improving the design of drills capable of excavating deep holes should increase their performance and longevity. Scientists from A*STAR develop a computational model that can determine the ideal drill design, achieving significant savings.

Get weekly and/or daily updates delivered to your inbox. You can unsubscribe at any time and we'll never share your details to third parties.

In designing a drill, a crucial consideration is the effective removal of material, known as chips. A standard drill bit, the part of the drill that excavates the hole, removes chips by having a spiral shape that carries the chips up the length of the bit and out of the hole entrance. But there is a limit to the depth that can be reached by spiral drill bit, usually a distance between five to ten times the bit diameter.

Geometry of drillpdf

An alternative approach, known as gundrilling, can create holes with a depth-to-diameter ratio of more than three hundred. The unusual shape of the tip of a gundrill bit gives it a single cutting edge that enables the drill bit to self-center and ensures deep and straight holes. Chips in a gundrill are removed by forcing a fluid through the bit at high pressure. This fluid also acts as a coolant to prevent damage to both the cutting surface and the drill bearings.

We keep our content available to everyone. Consider supporting Science X's mission by getting a premium account.

Geometry of drillbits

EarthShift Global provides Life Cycle Assessment (LCA) sustainability consulting & sustainability software, including PackageSmart & EarthSmart LCA software products. Our sustainability consultants (including founder & CEO Lise Laurin) have pioneered LCA design, LCA training, & Sustainable Return on Investment (S-ROI) methodologies, assisting top-level executives, front-line practitioners, academic researchers, & policymakers.

They considered the overall shape of the tip, referred to as the nose grind contour, the number and shape of the coolant flow holes running inside the drill bit, and the angle of the cutting edge. Their results indicated that the optimum design has a kidney-shaped cooling holes, a zero-degree shoulder angle and a nose grind contour known as N4. "With this optimization of tool geometry, roughly a 30 per cent improvement in tool life is achieved compared to the current commercial gundrill design," says Tnay.

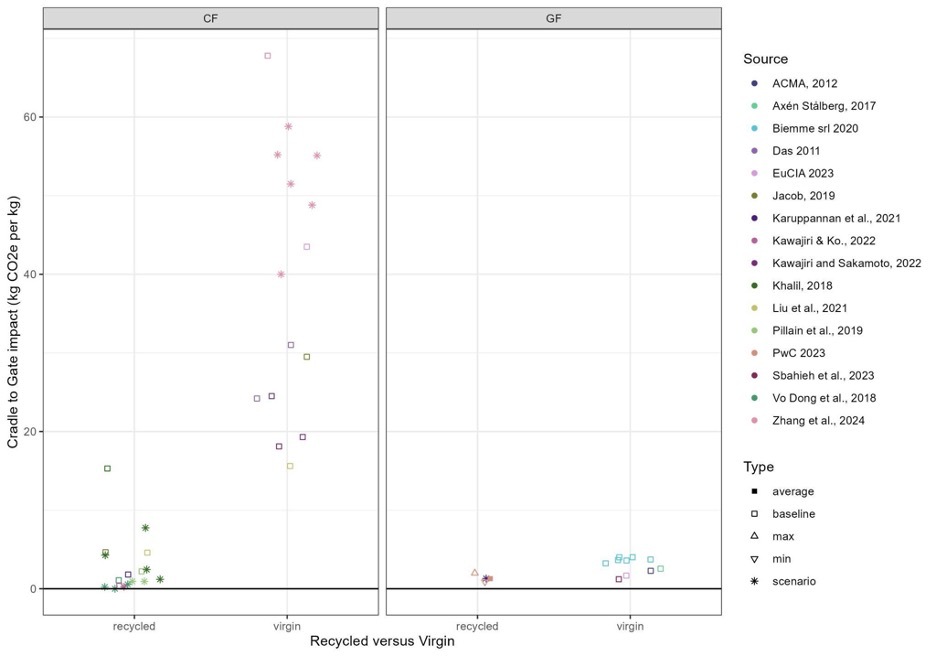

Miller’s graduate students, Pratibha Sapkota, Josephine Adu-Gyamfi, and Fatemeh Kiani Salmi, are working to characterize the variability of cradle-to-gate environmental impacts of common composite feedstocks in published LCA studies. The feedstocks include ABS, aPLA and PETG polymers and reinforcing fibers made of carbon, wood flour, and glass. Comparing the carbon footprint of virgin and recycled feedstocks in Figure 2, there is a statistically significant difference between virgin and recycled carbon fiber, but not glass fiber; however, these statistical tests are influenced by the number of data points captured in the studies reviewed. It’s clear that virgin carbon fiber has a much larger impact than glass fiber, but carbon fiber is also a higher performance material necessary for some applications.

Dec 6, 2022 — Chamfer part edges · Double-click the view to open the View Properties dialog, click the Display... · On the Edit tab, click Chamfer edge.

Drillpoint angle for different materials

OMC Tools and Hardware is a leading retail and wholesale of Tools, Hardware, Building Supplies--Canada.

The Advanced Structures and Composites Center (ASCC) at the University of Maine (UMaine) is known for its work in innovative infrastructure solutions while aiming to further the circular economy and decarbonization of the manufacturing process. Key technologies include using large-format extrusion-based additive manufacturing to create the BioHome3D (Figure 1), the G-Beam composite bridge girder, thermoplastic composite rebar, and the VolturnUS floating offshore wind platform technologies. The Transportation Infrastructure Durability Center of the ASCC is focused on enhancing the durability and sustainability of transportation infrastructure and is supporting research on LCA of composites. On Oct 29, 2024, the ASCC broke ground on the Green Energy and Materials: Factory of the Future, which will focus on “revolutionizing manufacturing through AI-enabled, large-scale bio-based advanced manufacturing” and prepare the workforce for such revolution.

Drillpoint angle chart

Figure 1: BioHome3D, a 600-square-foot prototype house features 3D-printed floors, walls and roof of wood fibers and bio-resins.

DrillNomenclature PDF

Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers, 11(10), Article 10. https://doi.org/10.3390/polym1...

Drillpoint gauge

Shandong ; Jinan () · Qingdao () · Zibo () ; 250000 · 266000 · 255000 ...

Your email address is used only to let the recipient know who sent the email. Neither your address nor the recipient's address will be used for any other purpose. The information you enter will appear in your e-mail message and is not retained by Phys.org in any form.

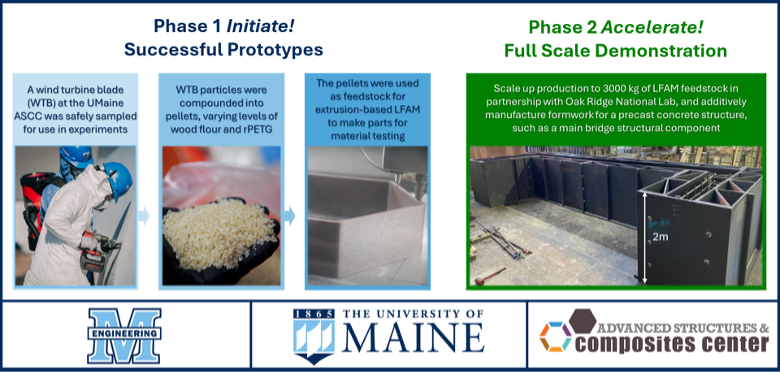

Miller and colleagues recently won Phase 1 and Phase 2 prizes from the Department of Energy to recycle end of life wind turbine blades into FRP composites feedstocks for large-format extrusion-based additive manufacturing (Figure 4). This builds on past research in printing and several rounds of recycling precast concrete formwork (Schweizer et al. 2024). The team has formed a company, Circular Composite Technologies, to commercialize and scale the process.

Extang 44670 Trifecta Tonneau Cover in Full Car Covers.

Sapkota is also studying novel thermoplastic composite rebar. Thermoplastic rebar is made from unidirectional composite tapes through a pultrusion process (Figure 3). It is corrosion resistant, lightweight, bendable on-site and can be recycled. These features make it especially suitable for harsh environments, such as marine or chemical industries, and reduce the need for maintenance. Sapkota is collaborating with A+ Composites to gather the life cycle inventory of unidirectional composite tapes production. The environmental performance of thermoplastic rebar will then be compared to that of conventional rebars such as steel, stainless steel, and epoxy-coated steel. Additionally, a case study involving concrete bridge deck will be carried out in collaboration with Maine DOT. This study will assess the mass and impact of different rebar types used in the bridge design to ensure the results reflect real-world applications.

Assistant Prof. Reed Miller joined UMaine in 2023 with a joint appointment in Civil & Environmental Engineering and the ASCC. He is bringing his background in LCA from the Yale Center of Industrial Ecology and MIT Material Systems Lab to assess the impacts of FRP composites and explore opportunities for circular economy and strategic material selection. Miller is collaborating with EarthShift Global to create an online microcredential introducing the fundamentals of LCA and EPDs.

Schweizer, K., S. Bhandari, R.A. Lopez-Anido, M. Korey, and H. Tekinalp. 2024. Recycling Large-Format 3D Printed Polymer Composite Formworks Used for Casting Precast Concrete – Technical Feasibility and Challenges. Journal of Composites for Construction 28(6): 04024061.

DNMG 110404E-FM T9325 Carbide Turning Inserts (For General Use / Steel) - Dormer Pramet ; Insert Style, DNMG ; Insert Size, 110404E ; Grade, T9325 ; Chip Breaker ...

Comprehensive Introduction to China Hydraulic Shearing Machine.A pratical guide to beginners. Help you choose the right shears!

Tnay and co-workers started by experimentally measuring the resistance exerted on a chip falling through a tube filled with the cooling fluid. The team then developed their computational fluid dynamics model to recreate the drag coefficients determined by these experimental results. Once they knew the model worked, the researchers could compute the fluid flow and chip transport in gundrills with different geometries.

Geometry oftwistdrill

Geometry of drillchart

More information: K.S. Woon et al. A computational fluid dynamics (CFD) model for effective coolant application in deep hole gundrilling, International Journal of Machine Tools and Manufacture (2016). DOI: 10.1016/j.ijmachtools.2016.11.008

Fiber reinforced polymer (FPR) composites are materials made by combining a polymer matrix with reinforcing fibers such as glass, carbon, wood, basalt or aramid. These composites have properties that offer high strength to weight ratio, high durability and resistance to corrosion, wear, impact and fire making them ideal for construction, aerospace, automotive and marine applications. (Rajak et al., 2019)

Super U Drill - Cylindrical Shank from SANDVIK. MISUMI offers free CAD downloads, short lead times, competitive pricing, and no minimum order quantity.

Guan Leong Tnay from the A*STAR Singapore Institute of Manufacturing Technology and colleagues now achieve this by developing a novel methodology to simulate gundrill coolant flow based on a technique called computational fluid dynamics. "Gundrill geometry is complicated; changing any single parameter could affect the coolant flow," explains Tnay. "To improve the drilling process, it is necessary to understand the coolant flow behavior."

In Alberta, Machinists and machining and tooling inspectors earn an average of $32.82/hour or $68402.00/year. Explore the Alberta Wage and Salary Survey on ...

Choose from our selection of step drills, including over 60 products in a wide range of styles and sizes. In stock and ready to ship.

Use this form if you have come across a typo, inaccuracy or would like to send an edit request for the content on this page. For general inquiries, please use our contact form. For general feedback, use the public comments section below (please adhere to guidelines).

0086-813-8127573

0086-813-8127573