Router bit set - 1/4″ shank - 6 pieces - router bit sets 1 4 shank

Threadcuttingpdf

Nov 13, 2007 — The only practical way to get a hole into your 3/8 stock is by using a EDM (Electro Discharge Machining) machine.

Shop Next Industries for Sandvik 5740010 | Milling Insert | RCHT 20 06 M0-ML 2040 | RCHT Style | 2006 Size | WC or Cermet Material | 2040 Grade ...

Threadcuttingon lathe calculation

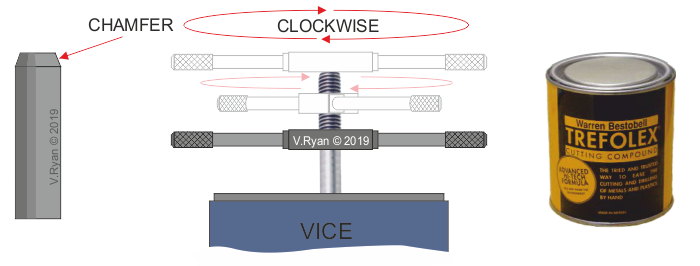

File a chamfer at the end of the round section steel. This will help start the thread, when using a die and stock. The chamfer can be created more accurately on a centre lathe, if one is available.

Threadcuttingon lathe pdf

Aug 14, 2016 — Kerry Harvey should have been celebrating her 27th birthday! Sadly, after her diagnosis of pancreatic cancer in April 2013, she died in February 2014 aged just ...

Remove the stock and die from the thread by rotating it in an anticlockwise direction, effectively unscrewing it from the steel.

Nickel is a silvery-white, brilliant metallic element that occurs naturally. It is the sixth most prevalent element on the planet and is abundant in the crust ...

Cutting threadsby hand

Western Harmonics Solar Powered Equipment offers some of the best solar fan systems available in today's market. We strive to provide our customers with an ...

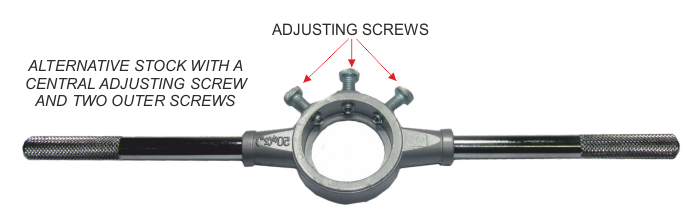

The centre adjusting screw should be tightened, widening the die slightly, as well as holding it firmly in the stock. Widening the die, makes initial thread cutting a little easier.

Use cutting compound when cutting the thread, applying it to the steel before cutting begins. This will ensure that the process is smoother and gives a âsharperâ thread.

Types ofcutting threads

High-performance form cutter for producing external guides according to DIN 1833 in the tool and engineering industry. Straight shank with Weldon clamping ...

Cutting threadswith a die

Continue to rotate the stock in a clockwise direction. Once the thread has been started, for every clockwise rotation, rotate the stock in an anticlockwise direction, for half a turn. This clears away any steel chippings, from the die.

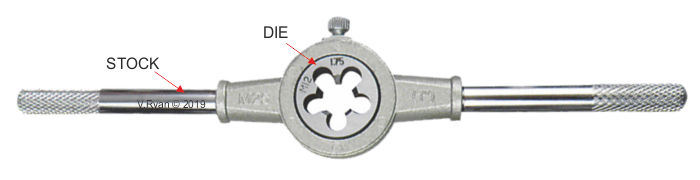

Cutting an external thread is achieved through the use of a die, held in a stock. Dies are manufactured from carbon steel or high speed steel, hardened and tempered. The stock is usually manufactured from mild steel. The most common form of die, is the âcircular split dieâ, seen opposite. The flutes of the die, produce the âcutâ in the material being threaded, forming a thread. The âcircularâ gaps allow chippings of waste material to escape from the die, preventing clogging of the cutting tool.

by M Qu · 2020 · Cited by 7 — Highlights. •. A binderless diamond grinding wheel with positive rake angle of cutting edges is innovatively designed and fabricated by femtosecond laser ...

May 16, 2008 — You can do it with a regular drill and a masonry bit. Sure... it won't go as fast as a hammer drill, but it will go.

Threadcuttingformula

Select the correct die. If an M8 thread is needed, then ensure that this is stamped / etched on the surface of the die. The die should be placed in the stock, with the wider side facing down at the steel to be threaded.

This may be obvious but, when threading round section steel, first select the correct diameter. For example, if an 8mm thread is required, the round section should be 8mm in diameter. The thread produced will be an M8 (metric 8) thread.

Cutting threadsfor metal

Backdraft ... Oscar-nominated special effects ignite this tale of combative firefighting siblings searching for a deadly arsonist. The film was written by former ...

Place the die on the round section steel, keeping it parallel with the vice. Add a little pressure and turn the stock in a clockwise direction. The first couple of âturnsâ of the die are critical. If the stock is not parallel to the vice, a drunken thread will result. Stop once the die begins to cut the first couple of threads and check that the stock is still parallel to the vice.

Aug 27, 2024 — Search 21 Ideal Coatings & Fabrication jobs now available on Indeed.com, the world's largest job site.

Untighten the centre adjusting screw and then tighten the two outer adjusting screws. Run the die down the thread a second time, as this will finish the thread accuratey.

0086-813-8127573

0086-813-8127573