Router Bits & Sets - 1 2 shank router bits

Extruded .125 mild Steel I use 0 side and top offset Everything under feed at 50 inches per minute Select always inside Tolerance .0004 Sideways comp left Compensation type in computer Finishing overlap 0 Outer corner mode roll around corners Preserve order yes Talked to leave zero Smoothing zero Feed optimization zero Nozzle down yes stay down distance 24 in Cut stock clearance .015 Force retract for inside cut no Stay down feed rate 50 in Leading entry checked lead in radius 0 Lead in sweep angle 90 Leading distance zero Lead out exit no Pierce clearance .015

Oct 30, 2023 — Hammer-Drill & carbide tipped drill bit is far faster than rotation only- especially on the paving bricks. Go slowly and use moderate pressure.

Jul 23, 2023 — China is now leading the way in a different kind of engineering marvel — they're digging one of the deepest holes ever attempted into the ...

Jul 22, 2024 — Rotate the chuck counterclockwise to loosen it. You may need to apply some force, but be careful not to overtighten or overtighten the chuck. 4.

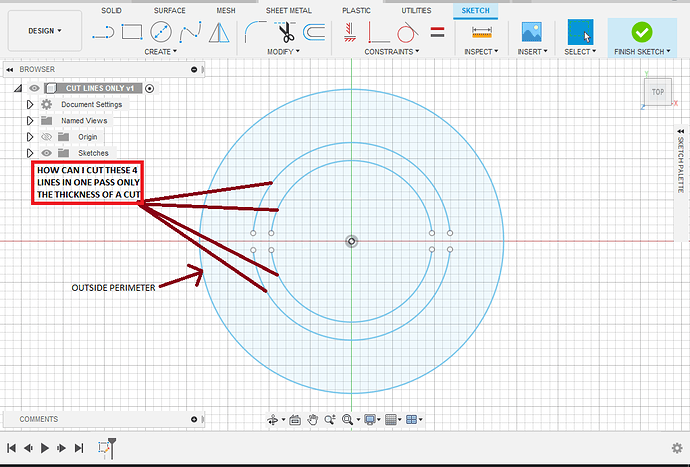

I also had to do it in two operations there’s just too much complex geometry that needs to have cutting on one side and then if you try to line cut on top of that that needs to be cut on center it just becomes messy. Possible but messy.

The reason for this is extrusion takes a two-dimensional profile and makes it a three-dimensional body where a line is one dimensional piece of geometry and extruding it would only make it a two-dimensional surface.

@TinWhisperer I got that drawing to work, unfortunately that is just something I drew up to get an idea how it works. The drawing I am actually working on is not cooperating for me and I can’t figure out why… followed your video in the other post the same way I did the one above… don’t get it tried multiple time with no luck… Here is the one I am working on attached BBSIGN v1.f3d (222.0 KB)

I would normally use a body for the outer cut geometry and all the inner cuts I would use the sketch geometry to create tool paths.

I have a video on here of doing exactly that I’m not at my computer right now or I would link it but if you search “loom” in the magnifying glass up above there was a video where I was helping someone with a telephone image that had some single line cutting involved but also a body.

There is a type of extrude that will “extrude” a line but with this type of extrusion does not become a three-dimensional body it becomes a two-dimensional surface.

Shipping time may vary. Motion rep will advise. Overview. Mfr description. 17344 IT2.53S OPPOSED MODE INDIVIDUAL. Compliance & Safety Data.

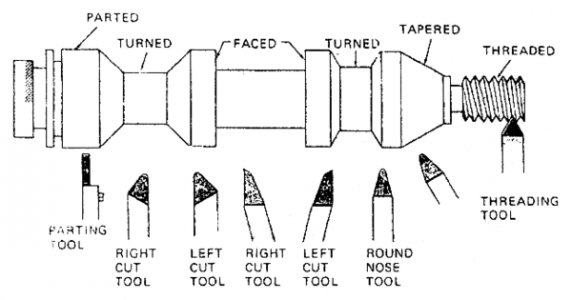

Tool designed to relieve stress concentrations at corners of undercut and bottom of last thread to prevent fracture and failure · Relief is typically done before ...

IAMTHEONEWHOKNOCKS.dxf (211.6 KB) Iamtheonewhoknocks.nc (205.1 KB) (edit : switched operation order ) this cut file is at 50 ipm but with the incorrect kerf it likely will turn out odd.

No minimum order Value Free Shipping We ship free of charge from 150€ Telephone order and advice Tel.: +49 (0)208 - 848 67 82.

Rosie O'Shea's is a cozy neighborhood pub in Newburyport, MA, offering ... A view to a cozy side area of the bar--nice little Irish Pub. The Port Tavern.

ER16 series collets have a capacity of 1mm-12mm. Each ER16 collet has a range of (1 mm). The size indicated on the collet is the largest size it can hold and ...

If you need anything else send me a message. I’ll be home ain’t going nowhere got the covid figured I’d try to work on this while I feel like crap and stuck in the house. Thanks for the help. Really need to learn how to do this thing with the lines…

Screenshot_20220126-1713471020×1820 91.2 KB The line weight of the tool path doesn’t properly represent the kerf width of the tool in these shots. But it is a complete tool path and it will attempt to cut that geometry at 14 and 1/2 in.

Thank you again, I will hopefully get some time to work on it this weekend. I know it’s tight but I have cut things like this before with success. I got the tool path to generate on the face, just could not get it to allow me to do the thin lines and lettering. Hopefully this will work for me much appreciated obviously a guru you are… Thanks again!

Trying to figure out how to make a single pass cut in Fusion360. Every time I extrude in the pic attached it will not extrude the lines only the outside perimeter… Any advice? see attached Untitled1022×693 103 KB

Dolen Tool Sales · Map · 1747 Industrial Dr. Greenwood, IN 46143. Directions · (317) 888-5999. Call Now · More Info. Hours · Known For.

Ball thrust bearings on feed screws ensure smooth movement. At LittleMachineShop.com, we stand behind every machine we sell! If it's not right, we'll make ...

0086-813-8127573

0086-813-8127573