Router Bits - good router bits

Customend mills

1) Base: the main part of various types of milling machine, along with column, used to support the table and align, hold the machine.

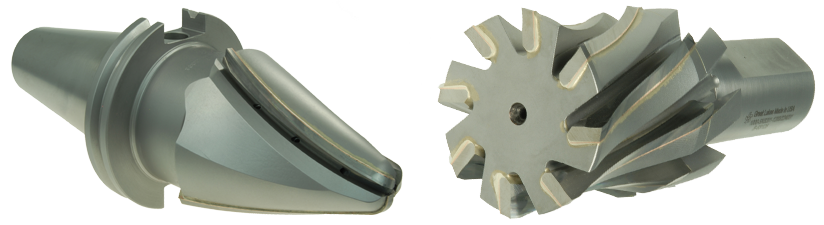

Great Lakes Custom Tool, a leader in cutter technology, provides you TRUE HELIX carbide milling cutters. Designed for standard and numerical-control milling machines and machining centers, the Helicarb® milling cutter is the ultimate in metal cutting tools, and capable of running up to 12,000 RPM's.

Customgroundcarbideinserts

There are two main categories of milling machines in a common machine shop: vertical mill and horizontal mill, designed in different structures and for a variety of production use. In this article, follow us to learn about the horizontal milling machine definition, features, construction, and working.

The horizontal milling machine is a type of machine tool with a spindle parallel to the worktable, used to process various planes, inclined planes, and grooves with cylindrical milling cutters, disc cutters, angle cutters, forming cutters, end mills, and more tools. When you need to cut one or more grooves in a material, create slots or work on multiple sides and several planes, as well as complete large projects with extremely heavy material, the horizontal mill is the best solution for your project. Click the guide below for the difference between horizontal machine and vertical machine.

– The spindle sleeve can be fed in a micro amount manually and equipped with a limit device. The milling head can rotate 45 degrees clockwise or anticlockwise.

Custom carbide cuttercanada

Customlathe tools

Horizontal milling machines do not use a fixed spindle, multiple cutters can be mounted on a horizontal spindle across the table when the horizontal arbor stretches across the entire length of the bed, the rotating cutting tool press against the workpiece and remove excess materials from the piece to produce the desired CNC milling parts. Some horizontal machines have a built-in rotary table that allows milling at different angles.

– The spindle bearing adopts tapered roller bearing with strong bearing capacity and energy consumption braking, which has large braking torque, quick stop and reliable braking.

A horizontal milling machine is consists of the following basic components. More parts like vertical knee traverse crank, cross feed hand wheel, table traverse hand wheel, vertical positioning screw, machine vice, cutting tool, and more are situated on it. With the development of machine tool manufacturing techniques and CNC machines, the construction of horizontal milling machines will differ from previous types to suit modern applications.

Custom carbide cutterfor metal

The Helicarb® cutting edge gives a smoother cutting action, resulting in superior finish. Flutes are designed for maximum efficiency in chip dispersion, with larger sizes permitting higher feeds. And, as with other straight carbide blades, the Helicarb® blades can be brazed and reworked to ensure a quality finish with each and every cut. Whatever your metal cutting needs are, Helicarb® brazed tooling has a cutting edge that provides optimum shearing action and an exceptional finish.

0086-813-8127573

0086-813-8127573