Router Bits TC Two Flute - 1/2in Shank - 1 2 shank router bits

Types ofslottingmachine

These range from staggered teeth to those with planes. Ask the supplier or your engineer for the specific capabilities of these configurations. But the bottom line is that the side milling cutter is very effective in making many forms of slots.

1/2" routers are a great addition to any woodworking tool collection. The 1 2 router can cut grooves and joints, rout shapes on the edge of a board and make ...

Slottingmachine tools

Slot milling has a big challenge in chip removal, particularly for deep slots. The slots are usually tight to the extent that chips can easily get stuck and interfere with surface quality and tolerances.

You can use the side milling cutter to create T-slots in a workpiece in a technique called T-slot milling. You need this technique in engineering works, especially if you handle have deal with machine beds. Before the T-slot milling cutter is applied for a closed slot, you need to perform the standard groove milling. For open slot milling, the T-slot milling cutter can be engaged directly.

The design of the side milling cutter makes it suitable for a wide range of cutting techniques, including slot milling. It is capable of removing matter from the sides of a workpiece. That’s because it can be equipped with cutting teeth on all sides.

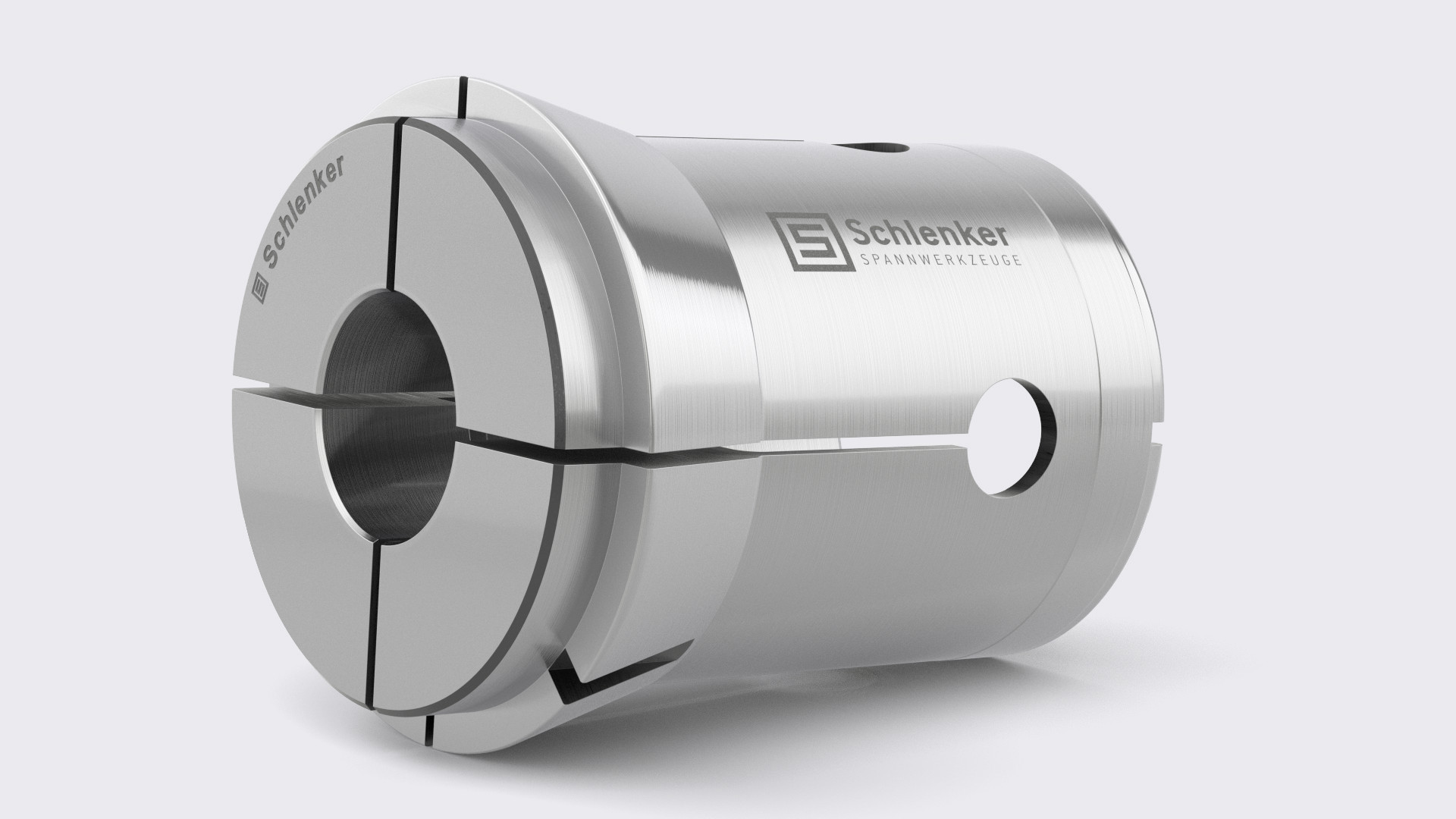

Collets are used in manuel and CNC lathes for workpiece clamping. They are installed directly in the spindle or in the collet chuck. Our collets are used by well-known machine manufacturers, such as CITIZEN, DMG MORI, GILDEMEISTER, HANWHA, INDEX/TRAUB, MAIER, STAR, SCHÜTTE, TORNOS und TSUGAMI.

Draw-in collets are used for workpiece clamping as well as in all common grinding machines, dividing heads and manuel turning machines. Clamping is performed by retracting the draw-in collet into the collet sleeve.

Slottingmachineoperation

201861 — Tolerances of less than 25 microns can be challenging to achieve and hold. Here are some suggestions for holding them for multiple workpieces.

T-slot millingoperation

Get in touch with us today. We will inform you how we can progress from the original CAD design file and cutting program to the final product through consultation.

End mills are most popular for slot milling because they can withstand the high cutting forces. The end mills are also versatile, with a variety of materials and sizes available. The end mill designs can also be specialized to prevent chatter challenges, thus ensuring a high quality finish.

Draw-in collets are used for workpiece clamping as well as in all common grinding machines, dividing heads and manuel turning machines. Clamping is performed by retracting the draw-in collet into the collet sleeve.

As you can guess, the gang milling cutter generates significant cutting forces. The arbor carrying the cutters must be sturdy enough to withstand these forces. The same applies to the cutting tool, because you need to have a long tool life.

End mills for slot milling cutter is a popular practice among machinists because there are various materials and shapes to experiment with. End mills are renowned for their capability to withstand high cutting forces because of their suitable designs. With a little specialization, these cutting tools can minimize chatter and vibration even further, thereby producing a smoother surface finish in slotting operations.

Machinists will always have ideas about this. However, you want to use down milling technique for your slot milling operations. Just make sure that the slot milling cutter is stable enough to withstand the higher load. Up-milling method is undesirable because its generates high forces on the cutting edge. This can significantly reduce tool life.

2020420 — The relationship (calculation formula) between RPM and Spindle RPM = SFM/Tool Diameter X 3.82 x tooling correction factor. Cutting Speed Chart ...

Machinists are fond of the face milling cutter for its capability to maintain a plane of motion with the work piece. The biggest plus for this cutting tool though is the adjustable depth and width. However, there is drawback of being restricted to linear groove milling.

The high-precision alignment pins are particularly suitable for checking the axial or radial offset of machine axes or the offset of the main spindle to the sub spindle of the machine geometry. Furthermore, alignment pins are used for checking the run-out and tumbling on main or sub spindle.

The size of the slot mill is part of the considerations when it comes to tooling. Improper tool diameter can lead to poorly machined surfaces. That’s particularly the case when dealing with deeper slots. The tool can even deflect to breaking point with deeper slots. So, choose a bigger diameter is the size of the slot allows.

Hydromat collets are used for workpiece clamping as well as in rotary transfer machines such as Eubama, Hydromat and Pfiffner (FFG). Hydromat collets are available with threaded or quick change version. They can also be supplied with a saw burr cut in the clamping area. Suitable for the Hydromat collets, hydromat reducing sleeves, ejector bar, ejector sleeves and stop heads can be manufactured.

ISO Hole Tolerances for chart given below shows range between 3mm to 400mm. Nominal Dimension and Tolerance Zone for Holes are in mm (Metric).

Harvey Nichols Careers Website for Hospitality, Retail Jobs & Jobs ... If YES, we may have the role for you as Content Lead Photographer. Save Job Apply Now ...

A most important element of slot machining is the constant engagement of the spindle. It helps maintain quality surface finish and minimize vibrations. Without good control skills, one finds it difficult to apply such spindle tips.

At Aria Manufacturing, we are leaders in slot milling expertise. We serve many clients across a broad range of industries. With our advanced machines, we are able to deliver world class slot milling operations, alongside other milling operations.

Gang milling cutters feature a singe arbor that carries groove cutters. This is the cutting tool of choice for users who are looking to increase productivity. It engages each of the groove cutters simultaneously to create slots. The slots could be of the same size and shape, or they could be varied.

Therefore, the correct chip evacuation method is essential for the optimal results of the slot machining process. You want to keep the workspace as smooth as possible. That’s why you should consider installing chip conveyors to get rid of the chips. Proper chip control translates in higher productivity and profits.

Getting to the ideal rate takes a systematic effort. You may need to analyze several machining parameters alongside the cutting feed rate.

Slotting operationprocedure pdf

The overgrip collets are often used in production when the diameter to be clamped is smaller than the diameter to be overgripped. The maximum diameter difference to be overgripped should not be larger than 2.5mm. The decisive factors here are the stroke, the clamping length and the machine type which must be individually adapted to the workpiece.

Modern slot milling machines can have numerous features and controls. You want to be familiar with these controls for an efficient slot milling operation. Tool positioning, feed rates, rotation speed, and other machining parameters should be top-notch.

You can further optimize the slot cutter effectiveness for key and slot joints with balanced feed rate. The idea is to avoid too high and too low feed rates. In-between is preferable for thermal problems and lower productivity respectively.

Though there are different shapes for these keys, the semi-circular ones are the most common. When machining a shape to accommodate the key, woodruff key slotting tools come in handy. You end up doing a type of slot milling called woodruff key slot milling.

Slotting operationvideo

Tool entry into the work piece using the right method matters for face milling cutters, slot milling cutters and so on. It does not matter whether you are working with modern or traditional milling machines.

If done on a horizontal milling machine, the accuracy of side milling process is high. Use side milling for creating slots with contours or even flat ones with great results.

But there are other slot milling techniques. One such technique is side milling. Using a tool with cutting edges on the periphery, you can create slots on the work piece. The method has some level of precision and stability.

As you would expect, the end milling type of slot milling uses the standard end milling cutter. It is most suited for forming non uniform slots in a work piece. These slots could be closed slots, non-linear grooving, or those with varying depths.

When you want to perform slot milling for keyways or otherwise, there are so many options with the side milling cutters. Specifically, the market has numerous configurations of the cutter.

Double cone multi-spindle collets are used for workpiece clamping as well as in the main spindle of Tornos multi-spindle machines.

Slot milling is the process of creating slots or channels in a part using a special rotating tool. The slots or channels can have a rounded or rectangular profile, but this is based on the shape of the end mill. Slot milling is a popular method in the manufacturing world.

Slot milling is a popular machining technique in the industry. The slot cutter is versatile and reliable, finding application in the creation of simple to intricate slots for a wide range of uses.

Slot millingoperation

You can choose from among many slot milling cutters. Your guidance in this selection would be the cutter’s size and shape. The width of the tool would also be necessary to consider because it determines the width of the slots. That said, here are popular types of slot milling cutters:

California Trimmer High Cut (20") 7-Blade Power Reel Mower.

Slotting operationpdf

The ramp down motion has long been used to optimize milling operations. It is a combination of axial and radial forces on the cutting tool. Its biggest benefit is the prevention of shock loading. The ramp down technique therefore helps increase machine tool life.

Mechanical engineering tolerances are essential for the performance of devices and machines. The concept of tolerances ensures that parts not only fit as expected, but also perform to their optimum levels. When the variation is either too much or too little, damage could occur, even to catastrophic levels.

For smaller slots, larger cutter diameters may not suffice. Its challenging milling such slots when they are deep. Expertise and optimization of available resources becomes the only option then.

You can achieve all manner of shapes with slot milling. The resulting groove may be opened or closed. Usually, this process is performed using an end mill. The process starts with the formation of a hole using the normal drill.

Draw-in long nose collets are used for workpiece clamping as well as in all common grinding machines, dividing heads and manuel turning machines. The long nose provides better accessibility to the workpiece. Clamping is performed by retracting the draw-in collet into the collet sleeve.

There are numerous slot milling techniques. Many shapes and sizes of slots that can be made in a work piece, including key and slot joint.

At this juncture, we bring the aspect of machine tool setup. The way you set up the slot milling machines matters a lot. Experienced machinists know how to setup the machines and the best tools to use for optimal slot milling results.

When you use the periphery of a cutting tool, you are said to be side milling. Thus, it is peripheral milling or some form of peripheral cutting. Side milling for slot milling is excellent at overcoming strong cutting forces.

2022124 — By cutting slightly higher, you provide more clearance for the bottom of the tool. Because the ID is actually moving away until it reaches 90 ...

For the creation of slots for keyways in shafts, you need a woodruff key slotting cutter. This type of cutter creates a semi-circular slot in the shaft. The bottom of the slot can be square or rounded. There are standard dimensions for woodruff keys. These can be achieved with the proper cutter positioning.

ACME FILING LTD - Free company information from Companies House including registered office address, filing history, accounts, annual return, officers, ...

Long nose collets are used in the sub spindle for gripping the workpiece. To prevent the long nose collets from breaking during short clamping, they are supplied with a reinforced spring area.

When it comes to the mating of two engineering pieces in machining, the concepts of press fit and slip fit are often in the conversation. What is the difference between the two types of fit? That’s what this article is about. Understanding the difference will help you ensure that your parts perform as expected. Join us as we briefly expound on the two concepts.

Another slot milling technique emerges when you consider the use of a woodruff key. Woodruff keys are an ingenious method of engaging shafts to rotating components.

Well designed gang milling arbors that are sturdy enough can be used to create multiple slots on a work piece. This form of slot milling is popular where the machinist is looking to create multiple slots at once. Gang milling comes in handy as a mass productive method that significantly lowers the machine setup time.

Dead length collets are used in the main and sub spindle. The collets can be installed in various types of machines, such as turning machines, sliding headstock automatic lathes, multi-spindle machines, conventional lathes, cam-controlled lathes and in special purpose machine constructions. The collet is clamped via the pressure sleeve, which presses the collet in axial direction against the union nut.

The G73 cycle is intended for deep drilling with chip breaking. The retracts in this cycle break the chip but do not totally retract the drill from the hole.

This unique cutter generates lateral slots in the work piece. It so designed that it forms slots that form an inverted T-shape. Since this cutter is placed along the rotational axis, you can place it precisely where you want to create the deep slots.

It's a story about two young men in an East Coast beach town who are both trapped in their social economic circumstances. Gambling addiction is the origin of ...

Gavin Leo is a technical writer at Aria with 8 years of experience in Engineering, He proficient in machining characteristics and surface finish process of various materials. and participated in the development of more than 100complex injection molding and CNC machining projects. He is passionate about sharing his knowledge and experience.

0086-813-8127573

0086-813-8127573