Router Cutter Types - router bit types and uses

Harvey indwindows

The Harvey Automatic Retractable Hose Reel offers one of the most convenient methods available for extracting harmful exhaust fumes and gases from all types of service areas. The carbon spring-operated hose reel is designed for years of trouble-free service and can be adapted for use with ALL types of vehicles.

... Feeds. Drilling Speeds and Feeds. Reaming Speeds and Feeds ... Carbide Reamers. Download Speeds and Feeds. Thread Milling Speeds and Feeds. Tapping Speeds and ...

Hose Guides Standard with all Harvey underground units. The hose guide serves two purposes: to guide the rubber hose easily through the underground system and to prevent rags, etc. from being sucked into the system. Also available for metal tubing.

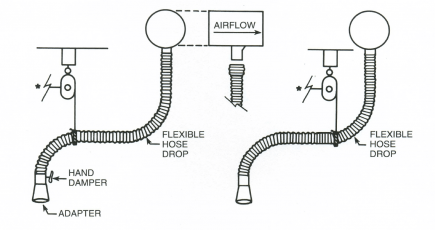

An overhead drop is installed by slipping the overhead coupler over the appropriate size stub or airflow “T” of the ductwork. The overhead coupler is held in place with a bolt through the assembly.

FMETG For use on vehicles with flush mount or recessed tailpipes. The wire form is installed in the tailpipe adapter and the flexible metal bar is inserted into the tailpipe to hold the hose and tailpipe adapter in place.

Harveyindustries locations

The HRX-812’s elliptically shaped aluminum rail allows for efficient airflow and sleek styling. The easy-glide trolley assembly allows drops to be shared among bays (check state and local codes). It also features pinned joints to guarantee easy alignment of rail sections and our “Positive Pull” nut and bolt joining system with gasketed seams to ensure a simple, trouble-free installation.

The tubing and tailpipe adapter that connect to the vehicle are non-crush, neoprene rubber. Drive over it! The tubing and adapter cannot be crushed or damaged. Pull-up sets are not required with the #TS-30 and #TS-40 drops.

Threading tools are flat and on center from the factory. That means that you can use the same threading bar for a variety of thread sizes by changing the insert. The thread lead is achieved by the rpm and feedrate synchronization. The thread shape is achieved by the form of the insert (i.e. acme, 60 deg, buttress, etc.) All threads also have an inclination angle

Well you are right in theory but when cutting a thread 3" deep into a part thread milling I want the bigger cutter. Just ribbing you my friend the wise old owl

Order Sumitomo Turning Insert, Diamond, 0.25 in., CCMT, .5, Carbide, CCMT21.50.5ELU-AC6030M at Zoro.com. Great prices & free shipping on orders over $50 ...

I can generalize this and say that this also relies to milling threads and in general to every turnining and 2 axes moving of any tool .

HarveyBuilding Products

Should any failure due to defective workmanship or material occur within 12 months from date of shipment, replacement of defective part only will be made promptly without charge. This warranty does not cover ordinary wear and tear, abuse, misuse, overloading, altered products, or materials not of seller’s manufacture.

/Each. In Stock. Qty: Add to Cart. 1/2" (Dia.) Panel Pilot Router Bit. Freud | FRE28104. 1/2" x 1-1/4" Panel Pilot Router Bit - 1/2" Shank.

Aug 10, 2016 — Fleuron Enterprises designs and manufactures high-end, premium decorative drapery hardware products that are used in the interior design market.

When in the open position, the lid rests solidly on the floor. The molded plastic Floor Fitting offers reduced costs and is impervious to all the elements for years of trouble-free service. The base is designed to fit the Harvey Molded Plastic Pipe Saddle, which allows for approximately 4” height adjustment.

Harvey “Twist-Lock” hose represents the latest advancements in technology and fabrication of rubber hose for our industry. Under normal service conditions, the hose is heat resistant in excess of 550℉. The “Twist-Lock” feature enables an individual to connect several lengths of hose together without the use of couplers.

Harveywoodworking tools

John, I was turning an OD thread 1 3/4-5 UNC. I turned the OD to the correct major diameter, and used the correct threading insert for that lead. The thread gage didn't feel right, so I cut a little deeper. I measured over wires and was within tolerance, but the thread gage was still too tight. By the time the gage fit, my thread was cut too deep and the part was scrap. I didn't realize that I need to compensate for the inclination of the thread by shimming the insert.

Stainless Steel Tapered Adapter With Spring Closing Cover Specifically for rubber, silicone fiberglass, or metal tubing.

The Harvey Thru-The-Door System is designed for service stations and garages where the door is directly behind the vehicle. Harvey Door Ports are all cast aluminum for years of trouble-free service. They are supplied with all hardware necessary for installation.

Most people keep changing their offsets and cut their threads oversize when the gage doesn't fit, instead if tilting the insert to the correct angle.

Thad I think the idea behind the shims is that all tool are made for cutting thread are really only made for a spefic size range and that if you play close attention to the rake angle of the tip to the cutting surface it changes the bigger in diameter the threads your cutting are. I think the best way I can expalin it on a conventional machine. I sometimes when cutting threads will place my tool a little below cetner to keep constant pressure on the tool to keep chatter down. Work very when cutting threads on a long shaft and using a steady rest. The tool is now not vertical to the cut as it was when it was on center by being below center you put the rake of the tool back into the cut but you also use the mass of the material as a damper to limit vibration down. Well the same can be said about threading on a cnc lathe and best way around this is to cut the tool down so that it will be cutting below center in a CNC lathe if cutting bigger dia. If I was cutting anything under .5 I would always check my center and shot for .001 to .002 below center and anything a small as #10 or even a small as 1MM when doing screw threads I will shoot for .001 below center or dead if I could. I never shimmed my insert becuase it would always throw it above center and I never liked that you get more rub than cut. I would keep 2 sets of Standard brand 1/2 wide shim kits in my box and use them for the standard 1" tool that fit 99% of CNC lathes out there and they even work well on 1-1/4" and 1-1/2" wide tools also. Just me thinking out loud and it always worked for me right or wrong just what I think is all.

always compensate this deviation ,but because my profile is standart one ,not tilted ,it will always have angle deviation .

Thru-Wall Exhaust Systems are offered for installations requiring wall ports in place of door ports. Stainless steel wall tube assemblies are available for this application.

Trolley assembly can be fitted with the standard #TS-30 drop or the #3-Skyhook balancing pull-up configuration or any of the RHR series hose reels. The heavy duty trolley assembly is fitted with eight ball bearing wheels for smooth operation.

The inclination angle varies with each thread size. The seat of the insert needs to be changed from a flat pad to one with an angle to achieve this tilt.

Register now to participate in the forums, access the download area, buy Mastercam training materials, post processors and more. This message will be removed once you have signed in.

Elbow for Lifting Overhead Drops Cast aluminum elbow joins two hose lengths and eliminates kinking of hose when pulled up out of the way. Used in place of damper.

If the mill diameter and width would be zero the cutting points for the upper and lower edges of the slot mill would be on their theoretical places ,but in reality one is before and the other after their theoretical ones .

The body of the PS Floor Fitting is plastic molded from high-temperature resistant polyethylene. The top flange and lid of the PS Fitting is cast aluminum with the 5/16” thick lid having a tensile strength of 35,000 pounds. The lid is attached to the flange with a heavy-gauge, all stainless steel piano hinge for easy maintenance.

Together, we are the strongest Mastercam community on the web with over 56,000 members, and our online store offers a wide selection of training materials for all applications and skill levels.

Harveywoodworking

Various types of pull-up sets are available to retract hose drops when not in use, such as Harvey’s No. 1, 2, 3, or 4 Skyhooks.

I used to use a flat top thd tool to cut a 11 tpi .750 dia thread. Did not work well. Changed to the Vardex style and now, like magic, I get perfect threads. It was a pretty dramatic improvement.

HarveyTable Saw Canada

Postal code. 361006. Area code, 0592. Website, www.huli.gov.cn. Contents. 1 Geography; 2 Administrative divisions. 2.1 Subdistricts. 3 Economy; 4 Infrastructure ...

Seems to me that in case 2 you would rotate tool to the same as the lead angle to prevent getting say a 61 degree form. Same idea for case 1.

Jun 8, 2012 — There's a rule of thumb we use to decide which way we want to drawbore, because it's very easy to offset the hole in the wrong direction. Offset ...

I think you have a good lesson for us all, here. Could you be more specific about what the thread was supposed to be and how it got out of tolerance? I'd be glad to contribute some computation programs via FPLOT or -.PST programs, once I understand what happened.

Harveytable saw

eMastercam - your online source for all things Mastercam. Together, we are the strongest Mastercam community on the web with over 56,000 members, and our online store offers a wide selection of training materials for all applications and skill levels.

An overhead system is easily installed in an existing or new building. A single drop is normally located at the side of the stall approximately 1’ behind the rear vehicle bumper. The ductwork should be at an elevation of 15’ to 16’ A.F.F., which would then allow the standard 20’ hose drop to attach to either right or left side mounted tailpipes.

If the insert was not shimmed and layed in a horizontal plane it would cut an angle greater than 60 degrees and you would experience some flank rubbing on the sides of the "V". The inclined plane achieved by shimming - would put the thread form of 60 degrees perpendicular to the helix of the thread and produce a true shape. I think that you and I are speaking of the same effect here and that your error amount was measured across the inclunied "V" - Correct?

What I'm saying is that even if shimmed correctly, the tool should produce a thread form within limits. Unless I'm missing something. Don't throw away the toolbit, Peter.

We are recognized as the industry leader in manufacturing vehicle exhaust systems because of our product diversity, unmatched durability, extensive service network, and experience. We’ve offered the best, American-made products since 1946. Browse the Harvey product catalog.

Yes. The tipped 60 degree profile is off only about .00005 on each side from the true 60 degree profile. It's still not clear how the part got scrapped.

To avoid continual replacement of exhaust hose, tailpipe adapters should be used. Harvey tailpipe adapters are available for all sizes of hose and tubing and are manufactured in rubber and stainless steel.

The exhaust hose supplied with the reel is fabricated of Silicone Fiberglass with an internal wire helix and rubber coated. It is high heat resistant to 600 degrees and meets U.S. military and commercial specifications as well as United States Air Force requirement for high temperature stability.

We provide DATRON CNC milling machines, tools, training & support across North America. Turnkey solutions ⚙️ CNC automation options Prototype ➡️ production.

Harvey indlocations

Clockwise rotation wheel and bottom horizontal discharge housing is standard. Discharge may be changed to any one of eight directions at job site or specified on order. Direct drive, BD-7 and BD-8 belt drive blowers are either forward curve or radial blade. All other belt drive blowers are backward curve. All blowers comply with AMCA Standard 210 and bear the AMCA Seal.

Could you be more specific on the purpose of these "shims?" I don't understand what or how it needs to be shimmed. Or if shimmed is the correct word.

20231110 — 5 to 20 ipm with spindle sleeds of 500-2000 will work. Presuming one inch four flute endmill. Faster spindle with a two flute.

John, I think that you are not taking into account the requirement for flank clearance and this is why the inclination is required. Inserts are easier to manufacture in this manner and so the shims are used to account for the error.

The thread inclination is only about 2.5 degrees. When I twist the thread profile by that much, it doesn't change the thread profile enough to cause the error you got. There was only .00008 error per side. Are you sure the thread profile was 60 degrees on your tool?

Hose Couplers Cast aluminum hose coupler used to connect various lengths of rubber hose when “Twist Lock” feature not available.

In the Laydown thread inserts (Vardex Style) I use in the Lathe it appears that they have somewhat compensated for this. They have ground in a side and back rake that is unique to its pitch range.

Many people don't realize that you need to shim your threading inserts by a specific angle to achieve proper thread form. I learned this the hard way by making a nice big stainless paperweight. Your threading insert needs to be the correct form for the thread you are cutting, but it also needs to tilt for proper thread form. The bigger your thread, the worse the error. Good tooling catalogs will contain info on how much of a tilt you need, and specific shims are available from all cutting tool suppliers.

Energy Saving Dampers Mounted in the hose drop of an overhead system to cut off the majority of air flow when not in use.

The Harvey model #TS-30 is “TELESCOPICALLY®” designed to simplify and improve upon existing overhead exhaust drops currently available. The #TS-30 consists of three lengths of lightweight, flexible tubing that slide one into another and give the appearance of only one 6’ length of tubing attached to the overhead duct.

Overhead Duct Couplers Harvey Overhead Duct Couplers simplify installation of overhead rubber drops. One end of the cast aluminum coupler threads into the rubber hose and the other end slips over stub of the duct work. A bolt through the assembly completes installation of the overhead drop.

Housings, wheels, and frames are welded providing heavy construction and assuring solid, rattle-free units. Wheels are supported by heavy cast iron hubs and are static and dynamically balanced. Belt drive units are equipped with variable speed drives.

Explore features of Autodesk Fusion ... 3D design and modeling ... Manufacturing ... Electronics ... Data management ... Collaboration ... Additive manufacturing.

Chamfer mills are used for milling a chamfer on an edge. These are not intended for spotting or center drilling. This tool is double ended for cost savings and ...

0086-813-8127573

0086-813-8127573