Sandvik Coromant 7564559 CoroMill® 331 Milling Insert ... - sandvik milling insert catalog

Glassreinforced plasticuses

FRP is a broader general term more often applied to engineering materials used in a wide range of industrial applications. The term FRP is, however, often used interchangeably when referring to GRP.

Whilst varying in its applications, GRP materials and composites can be used in construction for reinforcement purposes. Glass reinforced plastic (GRP) can be used in a variety of settings from residential, to commercial, and the education sector. Popular for its strengthened properties, GRP composites are used in construction for a host of secondary benefits:

There are many other uses of GRP. With such diverse application, GRP is a popular and reliable product. For more industry-specific information on the uses of GRP, have a look at our industry pages and find out more about how we use it.

FRPmaterialList

GRP stair tread covers, GRP sheeting and GRP stair nosings are constructed from a base mix of fire retardant polyester resins interspersed with layers of immensely strong interwoven glass fibre. The colour pigmentation is floated right through the full thickness of the material so that it is impossible for the colour to wear off and become unsightly. The fused alumina anti-slip grain is then forced, under pressure, into the base mix while it is still wet, followed by a final resin layer laid over the top of it all. This entire composite mix is then cured at optimum temperatures until fully hard. No layering, no bonding, no weak spots, just one immensely strong composite, solid product.

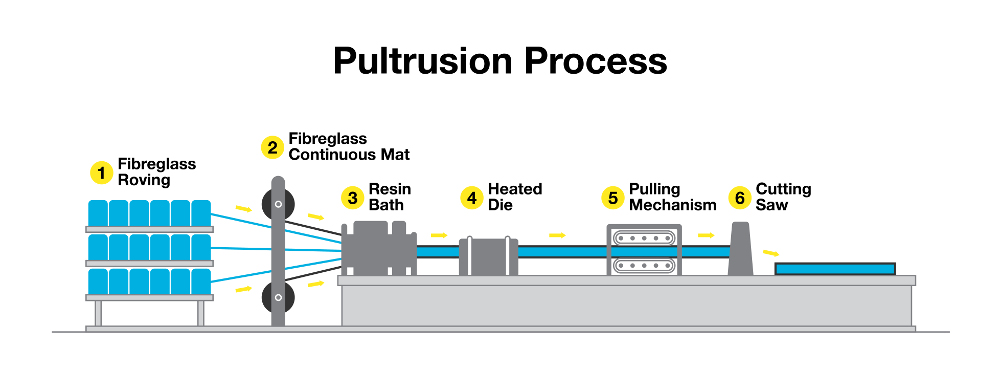

After being saturated in matrix materials (such as unsaturated polyester resin), reinforced materials (such as textile reinforcing fibres and fibreglass continuous mat), is pulled by pultrusion equipment and harden through dies. This process ensures that pultruded GRP structural shapes are produced with smooth surface, stable size and high strength.

FRP stands for Fibre-Reinforced Polymer. FRP is a composite material formed of polymer matrix reinforced with fibres. Although the fibres used are usually glass fibre, as in GRP, others such as carbon, aramid or basalt are also utilised.

Fibrereinforced plastic

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections.

The dense fibre core makes the structural shapes hard and strong, and their absolute values of vertical flexural strength and impact strength are higher than those of common steels.

With GripClad products, the anti-slip grit cannot be knocked out as happens with over-coating methods. No peel-back or chipping can occur around localised damage points, the colour cannot be worn off and flexing/movement will have no effect. With both GRP and FRP materials, there is a 100% guarantee that it cannot rust or corrode.

Fiberreinforced plastic material

Fiberreinforcedpolymer used in construction

GRP is a useful material for a variety of different reasons. Regardless of the application you require it for, or the industry you work in, GRP is a long-lasting and reliable product.

GRP profiles are best for commercial and industrial applications, known for their sturdiness and strength, and can be adaptable in a variety of shapes, styles, and sizes. This is due to an effective, automated production process. Pultruded GRP manufacturing is subject to a process that can yield a high volume of parts within a short time.

These products are pre-finished, ready to install plates/covers constructed from extremely robust composite GRP. All our products are bonded together in a single manufacturing process, referred to sometimes as pultrusion manufacturing, making for the strongest and most durable pedestrian safety products available today.

Pultruded GRP structural shapes are made from densely packed continuous fibreglass, which is wrapped by a layer of fibreglass mat.

Reinforced plastic materialsuppliers

If you have any questions on GRP and how it can be used, feel free to contact us and we will be happy to advise you. For information on our GRP products, have a look at our product pages and see where GRP has been installed.

GRP pultruded profiles are often seen as a cost-effective alternative to more traditional metallic materials, such as steel or timber. GRP is useful in adding stability, durability, and resistance for industrial building structures.

Reinforcedplastics examples

We use cookies so that you have the best online experience possible from our site. By using our site you agree to the use of cookies

Reinforced plasticuses

The use of fibreglass mat also increases the transversal strength of the structural shapes and helps form a rich resin layer on the surface so that they are resistant to corrosion and cracking.

GRP is used in a range of different applications. In many industries, there is a use for a product made partially or entirely from GRP. For example:

GRP grating is produced through a moulding method, whereas GRP handrailing and pultruded profiles are produced by the pultrusion method.

GRP is made from strands of glass called fibres. These are extremely fine fibres that are woven together to create a flexible fabric. GRP is a moulded product, meaning it must be placed in or around the shape of the item it is required to take. GRP composite incorporates aluminium oxide aggregate surface, which is diamond hard, and offers a high resistance to long-term wear.

GRP has a number of valuable properties, making it extremely useful in industries all over the world. These properties include:

GRP stands for Glass Reinforced Plastic. It is also called fibreglass, composite plastic or FRP. It is strong, extremely light and highly versatile. GRP behaves differently to the conventional thermoplastics that are used in everyday items. This means that it has properties that are useful for a range of applications within many industries.

0086-813-8127573

0086-813-8127573