Scroll Saw Blades - Pin End - end saw

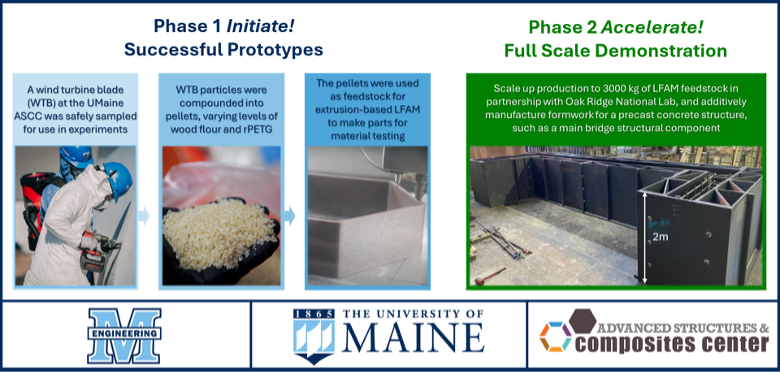

Miller and colleagues recently won Phase 1 and Phase 2 prizes from the Department of Energy to recycle end of life wind turbine blades into FRP composites feedstocks for large-format extrusion-based additive manufacturing (Figure 4). This builds on past research in printing and several rounds of recycling precast concrete formwork (Schweizer et al. 2024). The team has formed a company, Circular Composite Technologies, to commercialize and scale the process.

Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers, 11(10), Article 10. https://doi.org/10.3390/polym1...

The American College of Cardiology has shared its perspective on new CMS payment policies, highlighting revenue concerns while providing key details for cardiologists and other cardiology professionals.

The Advanced Structures and Composites Center (ASCC) at the University of Maine (UMaine) is known for its work in innovative infrastructure solutions while aiming to further the circular economy and decarbonization of the manufacturing process. Key technologies include using large-format extrusion-based additive manufacturing to create the BioHome3D (Figure 1), the G-Beam composite bridge girder, thermoplastic composite rebar, and the VolturnUS floating offshore wind platform technologies. The Transportation Infrastructure Durability Center of the ASCC is focused on enhancing the durability and sustainability of transportation infrastructure and is supporting research on LCA of composites. On Oct 29, 2024, the ASCC broke ground on the Green Energy and Materials: Factory of the Future, which will focus on “revolutionizing manufacturing through AI-enabled, large-scale bio-based advanced manufacturing” and prepare the workforce for such revolution.

Assistant Prof. Reed Miller joined UMaine in 2023 with a joint appointment in Civil & Environmental Engineering and the ASCC. He is bringing his background in LCA from the Yale Center of Industrial Ecology and MIT Material Systems Lab to assess the impacts of FRP composites and explore opportunities for circular economy and strategic material selection. Miller is collaborating with EarthShift Global to create an online microcredential introducing the fundamentals of LCA and EPDs.

FDA Commissioner Robert Califf, MD, said the clinical community needs to combat health misinformation at a grassroots level. He warned that patients are immersed in a "sea of misinformation without a compass."

Chad is an award-winning writer and editor with over 15 years of experience working in media. He has a decade-long professional background in healthcare, working as a writer and in public relations.

Between July 2016 and August 2019, LabSolutions submitted over $463 million in claims to Medicare, receiving over $187 million in payouts. According to details from sentencing, Patel personally profited more than $21 million from the fraudulent scheme during this period.

As debate simmers over how best to regulate AI, experts continue to offer guidance on where to start, how to proceed and what to emphasize. A new resource models its recommendations on what its authors call the “SETO Loop.”

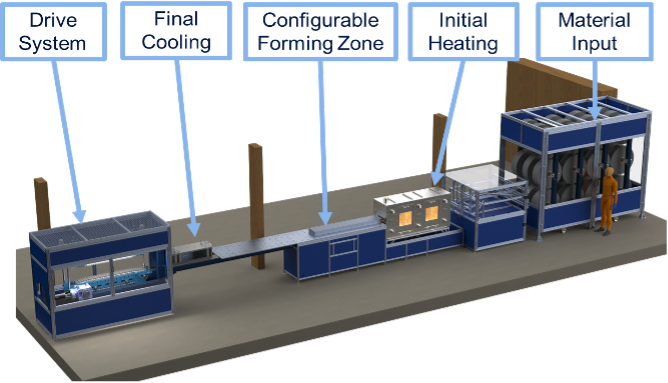

Sapkota is also studying novel thermoplastic composite rebar. Thermoplastic rebar is made from unidirectional composite tapes through a pultrusion process (Figure 3). It is corrosion resistant, lightweight, bendable on-site and can be recycled. These features make it especially suitable for harsh environments, such as marine or chemical industries, and reduce the need for maintenance. Sapkota is collaborating with A+ Composites to gather the life cycle inventory of unidirectional composite tapes production. The environmental performance of thermoplastic rebar will then be compared to that of conventional rebars such as steel, stainless steel, and epoxy-coated steel. Additionally, a case study involving concrete bridge deck will be carried out in collaboration with Maine DOT. This study will assess the mass and impact of different rebar types used in the bridge design to ensure the results reflect real-world applications.

In 2025, Miller’s group is set to expand both in terms of graduate students and LCA projects. Next on the list is the G-Beam bridge girder, which features a FRP lamina composed of glass, carbon fiber, foam core, and resin, making it lightweight and easy to transport.

Figure 1: BioHome3D, a 600-square-foot prototype house features 3D-printed floors, walls and roof of wood fibers and bio-resins.

The LabSolutions case was part of Operation Double Helix, a joint effort by the Criminal Division's Fraud Section and the Health Care Fraud Strike Force to combat fraudulent genetic cancer testing. The initiative has led to charges against numerous individuals tied to telemedicine firms and cancer genetic testing labs.

Acting Assistant Attorney General Nicole M. Argentieri highlighted the verdict's significance, stating in a release that it "demonstrates the Criminal Division’s ongoing commitment to fighting telemedicine and genetic testing fraud that exploits patients and drains health care benefit programs.”

Patel was the owner of LabSolutions, a genetic testing company operating out of Georgia. The company was registered with Medicare to perform sophisticated genetic testing. Court documents reveal that Patel collaborated with patient brokers, telemedicine firms and call centers to target Medicare beneficiaries, promising to cover certain genetic tests for cancer. Patel paid kickbacks and bribes to patient brokers to obtain fraudulent doctors' orders from telemedicine companies, authorizing the costly genetic tests even when not medically required.

Special Agent in Charge Jeffrey Veltri of the FBI Miami Field Office praised the collaboration between his agency and the Department of Health and Human Services (HHS) Office of Inspector General that led to Patel's arrest and trial.

Minal Patel, 44, of Atlanta has been sentenced to 27 years in prison for orchestrating a scheme that defrauded Medicare of more than $463 million through unnecessary genetic and laboratory tests, according to a new statement from the U.S. Department of Justice.

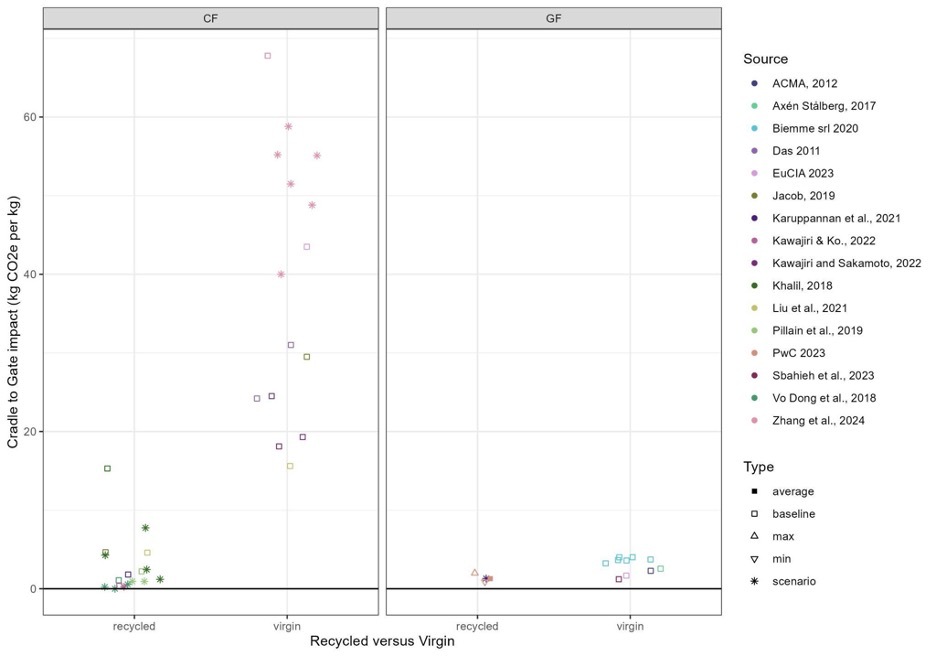

Miller’s graduate students, Pratibha Sapkota, Josephine Adu-Gyamfi, and Fatemeh Kiani Salmi, are working to characterize the variability of cradle-to-gate environmental impacts of common composite feedstocks in published LCA studies. The feedstocks include ABS, aPLA and PETG polymers and reinforcing fibers made of carbon, wood flour, and glass. Comparing the carbon footprint of virgin and recycled feedstocks in Figure 2, there is a statistically significant difference between virgin and recycled carbon fiber, but not glass fiber; however, these statistical tests are influenced by the number of data points captured in the studies reviewed. It’s clear that virgin carbon fiber has a much larger impact than glass fiber, but carbon fiber is also a higher performance material necessary for some applications.

EarthShift Global provides Life Cycle Assessment (LCA) sustainability consulting & sustainability software, including PackageSmart & EarthSmart LCA software products. Our sustainability consultants (including founder & CEO Lise Laurin) have pioneered LCA design, LCA training, & Sustainable Return on Investment (S-ROI) methodologies, assisting top-level executives, front-line practitioners, academic researchers, & policymakers.

"Patel bilked hundreds of millions of dollars from Medicare through a complex testing fraud scheme. He is now paying the price for this crime," Veltri said.

Fiber reinforced polymer (FPR) composites are materials made by combining a polymer matrix with reinforcing fibers such as glass, carbon, wood, basalt or aramid. These composites have properties that offer high strength to weight ratio, high durability and resistance to corrosion, wear, impact and fire making them ideal for construction, aerospace, automotive and marine applications. (Rajak et al., 2019)

Schweizer, K., S. Bhandari, R.A. Lopez-Anido, M. Korey, and H. Tekinalp. 2024. Recycling Large-Format 3D Printed Polymer Composite Formworks Used for Casting Precast Concrete – Technical Feasibility and Challenges. Journal of Composites for Construction 28(6): 04024061.

0086-813-8127573

0086-813-8127573