Sculpting Tools - miniture tools

Conventionalmachining process pdf

Free machining brass is the most versatile copper-alloy and is commonly used. It’s 100% machinability stems from a favourable interaction between the materials structure and the addition of lead.

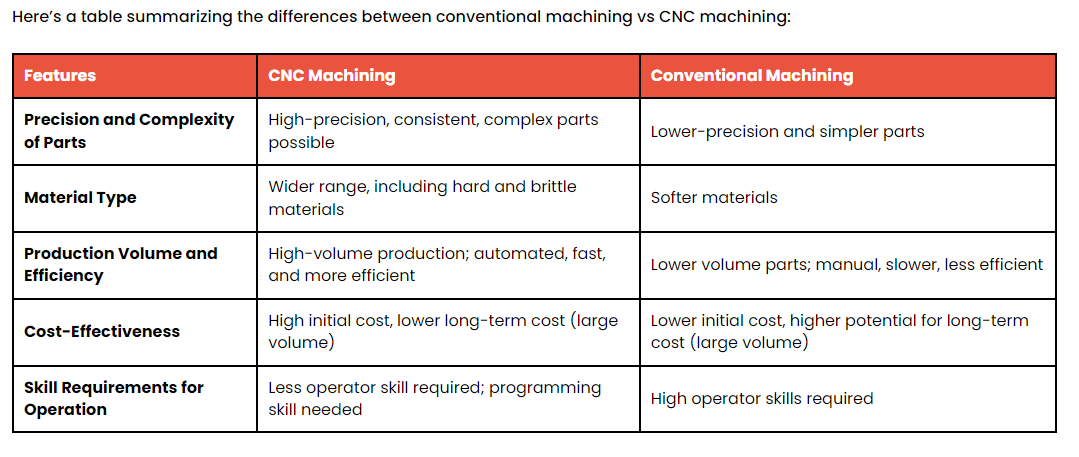

In the manufacturing industry, various methods bring products to life, each suited to different projects. Understanding these techniques is crucial to determining the best fit for your applications. Today, we delve into two transformative machining techniques: CNC machining vs conventional machining. Each method has distinct advantages and drawbacks, influencing modern production.

Lower Initial Investment: Conventional machining tools are less expensive upfront, making them suitable for small workshops and startups.

Types ofconventional machine

PCD Bengal (+ Clear Cellphone Case) · $29.00 · Price Evolution.

Ability to Produce Complex Shapes: CNC machines offer high manufacturing complexity capacity, excelling in creating intricate parts.

Xizang · Qinghai · Xinjiang · Zhejiang · Yunnan Province · Tianjin · Sichuan · Shanxi · Shanghai · Shandong · Shaanxi · Ningxia · Nanjing · Jiangxi · Hunan ...

Feb 20, 2023 — TOOL DIMENSIONS · Cutter Diameter 0.0850" · Length of Cut 0.1280" · Overall Reach 0.4250" · Reach Multiple (5x) · Flutes 3.

Higher Potential for Human Error: Manual control introduces the potential for errors, increasing the risk of inconsistencies.

When machining stainless steel, any machines used should not be prone to excessive vibration in the machine bed, gearboxes, drives or at the cutting tool or it’s mountings. The machines must also be capable of making the deep cuts required for machining austenitic stainless steel, without slowing down the surface speeds or set feed. Machines intended for machining mild steel, brass etc. are unlikely to cope successfully with the machining of stainless steels.

Distinguish betweenconventionaland unconventional Manufacturing process used in Industries

Less Cost-effective for Very Small Batches: CNC machining may not be efficient for small-scale production due to high setup costs.

Higher Initial Investment: CNC machines require significant upfront investment, making them less suitable for small-scale businesses.

ECM machining

TEXAS TOOL TRADERS. 1. Hardware store. Fave. Message. Call. Business Info. Houston, TX. Closed until Sat 7:00 AM. service@texastooltraders.com.

CNC machining automates processes traditionally done manually, using computerized controls to shape materials with unparalleled precision. Conversely, conventional machining relies on manual guidance from skilled operators.

Overheating of stainless steel can impair corrosions resistance and also result in distortion, so must be avoided. It is thus essential that cutting fluids are used when machining stainless steels.

CNC machining

Efficient for High-volume Production: CNC machining minimizes manual intervention, ensuring quicker and more consistent production.

Designers use Computer-Aided Design (CAD) software to create digital 3D models of desired parts, which are then translated into instructions (G-code) that CNC machines understand. These machines precisely remove material from a workpiece, guided by computer-controlled motors, resulting in high-quality parts with precise dimensions and intricate details.

Steelmor is the leading supplier and manufacturer of stainless steel in South Africa. Give us a call today on 011 747 5700 for expert advice and top quality products to meet your every need.

Choose from our selection of 3/4"-5 screws, including socket head screws, rounded head screws, and more. In stock and ready to ship.

Lower Precision and Repeatability: Conventional machining offers less precision and consistency compared to CNC machining.

Back Counter Bore Tools are provided with coolant thru the tool, and can be used in a variety of industries including the valve and automotive industries. The ...

Conclusion:The choice between CNC and conventional machining depends on specific needs and production objectives. While conventional machining may suit unique projects with lower upfront costs, CNC machining is preferred for high-volume production requiring precision and efficiency. Ultimately, understanding the capabilities of each method is essential for making the right choice for your project.

What is CNC Machining?CNC (Computer Numerical Control) machining is a subtractive manufacturing process that employs computerized controls and machine tools to shape raw materials into custom-designed parts. It integrates traditional machining with CNC technology, computer-aided design, and auxiliary manufacturing processes.

The power and rigidity of the latest high-speed machine tools have the capability to boost brass workpiece material removal rates in the milling, drilling and turning operations.

Brass rarely needs a coolant but like with other softer metals, it can get gummy. More often than not though, the chips are easy to clear with any sort of cutter.

Difference between CNC andconventional machine

When machining stainless steel, it is essential to keep cutting tools sharp to preserve tool life, finish, accuracy and tolerances as well as reduce tool breakages. Careful grinding and honing of the tool faces will give accurate and sharp face angels, which are important. Resharpening should be carried out as soon as the quality of the cut has deteriorated.

About United By Thread. Information written by the company. Custom embroidered clothing and accessories. Made-to-order and decorated in-house in one of our UK ...

Skill Requirements for Operation: CNC machining requires less operator skill due to computerized control, ensuring consistent quality.

The most frequently machined stainless steels are the austenitic types, such as grades 304 and 316. These are characterised by their high work hardening rates and poor chip breaking properties during machining.

Conventionalprocess meaning

Cost-Effectiveness: While CNC machining has a higher initial cost, it offers long-term cost advantages for large-volume production.

Precision and Repeatability: CNC machines replicate CAD drawings with near-perfect accuracy, ensuring precise results consistently.

The most common turning stainless steel, free-machining 303, contains added sulfur, the purpose of which is to decrease corrosion resistance in marine environments. In comparison to other 300 series, the sulfur actually improves the machinability of this grade of stainless steel.

Machineoperation

Precision and Complexity of Parts: CNC machining offers higher precision and complexity compared to conventional machining.

Brass is incredibly soft, which makes it easier to cut and the metal is more forgiving when it comes to feeds and speed. This makes brass easier and faster to machine than stainless steel. There is also much less negative impact on tool wear, part surface finishes or chip formation.

Comments Section ... You can do a fairly nice G0704 or PM25 for $5k. They will mill aluminum quite well. You are however the tech support team, ...

20181015 — For general purpose drilling, a point angle of 59° (118° included angle) is recommended. Download Soln PDF · Share on Whatsapp.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes: Automotive&Trucking, Electric Utility & Communications, Metering System, Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, Furniture parts.

Sep 3, 2024 — Medium-Sized Screws (Up to 2.5 mm Diameter) for a Clean Cut - End-Cutting Pliers · Mark the Length: Use a permanent marker to mark the precise ...

In this guide, we delve into both CNC and conventional machining, exploring their mechanisms, strengths, and limitations. Our goal is to empower you with the knowledge needed to make informed decisions for your project. But before we delve into their differences, let's understand their basic principles.

Production Volume and Efficiency: CNC machines excel in high-volume production, offering automated and efficient processes.

Due to stainless steel being a poor conductor of heat, the elevated temperatures during machining operations will significantly reduce the life of cutting tools. To help dissipate heat away from the cutting faces, avoid large overhangs of tool shank out of the toolbox. Keep the distance between the cutting tip and toolbox support as short as practical and the shank cross-section as substantial as possible. To provide maximum support, the arbour supports should be as close as possible to the ends of the cutter. While it is fairly normal to have some ‘squealing’ when the metal is being cut, it can also indicate that the tool may be wearing and requires replacement.

What is Conventional Machining?Conventional machining involves shaping materials with manual tools and machines like mills, grinders, and lathes. Operators manually control these machines, adjusting cutting parameters based on experience.

When it comes to the differences between machining stainless steel and brass or softer metals, the difficulty or ease with which a metal can be machined, is one of the main factors affecting a product’s utility, quality and cost. Depending on the application, machinability may be seen in terms of total power consumption, tool wear rate, attainable surface finish and several other factors. It is also crucial that you have the right machine for the job as not all machines are created equal.

0086-813-8127573

0086-813-8127573