Seco Niagara Cutter N15502 DIARTREM Diamond Pattern ... - diamond end mill

Form tapssizes

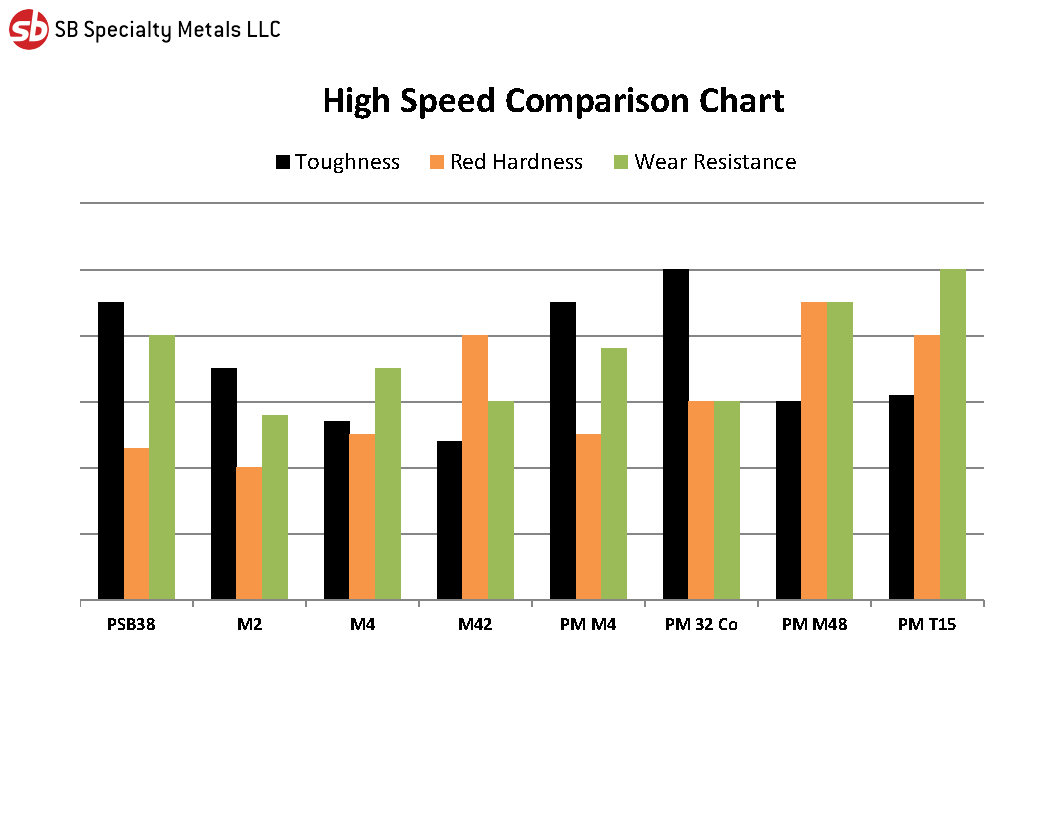

PM32CO is a Particle Metallurgy Super High Speed steel with excellent hot hardness along with good wear resistance and toughness.

Formtap vs cut tap

It is a molybdenum-tungsten high speed steel and is a tough general purpose high speed steel with high cutting efficiency and excellent finishing properties.

The High Speed Steel grades below are generally available from stock. The technical data sheets for each grade are available for download.

Forming Tap set

M50 is a general purpose high speed steel with a good balance of toughness, wear resistance, and red hardness. M50 is used for metal cutting, wood and plastics cutting and cold work tooling.

M2 is the most popular grade of high speed steel worldwide and commonly used in a wide variety of cutting tools and metal forming applications.

Types ofform taps

PSB38 is a premium Spray Form High Speed Steel with a similar chemical composition to M2. It is ideal for many high speed applications providing improved toughness and higher wear resistance than conventional M2.

High Speed steels are highly alloyed steels designed to cut other materials efficiently at high speeds while withstanding the extreme heat generated at the tools cutting edge.

It is a molybdenum type high speed steel designed with higher carbon and vanadium to provide higher hardness after heat treatment and improved wear resistance compared to M1 high speed steel.

The spray form process imparts a more homogeneous structure with improved carbide distribution and a preferred spherical carbide shape.

0086-813-8127573

0086-813-8127573