Shars ZCC External V Partial Profile G60 Carbide ... - g60 threading insert

The primary element found in the 7075 aluminium alloy is zinc. With zinc as the top alloying element, this aluminium grade obtains a series of properties that make it suitable for a wide variety of applications.

However, if you are still in doubt, the recommendation is to consult an expert. Do not hesitate to contact us, we will be more than glad to help you!

Milling machines are used mainly for shaping and cutting solid materials such as metal, wood, plastics or even brass. These machines differs ...

Because of the cost, you should only use it if your specific application requires the essential features of this alloy. Otherwise, you may be better off with a cheaper alloy.

Dimensions: 3.25" x 2". Tools include: Ruler l Metric ruler l Bottle opener l Flat head screwdriver l Mini screwdriver l Phillips screwdriver l Hex/Bit ...

We already mentioned that the aluminium 6082 alloy is widely used in structural components such as trusses and bridges. But of course, this could not be the only application for a material with such properties as those mentioned above. Machinery components are also commonly made with this aluminium alloy.

Aluminium recycling is one of the most efficient and environmentally sustainable industrial processes, playing a crucial role in waste management and...

Aluminium has become a very popular material for applications across many different industries and in CNC machining. Its popularity over other materials is associated with its excellent mechanical properties. If you want to learn all about the top 3 aluminium alloys, keep reading as we disclose all the details.

2021526 — Unlike most CNC cutting tools, Thread Forming Taps, otherwise known as Form Taps, Forming Taps, or Roll Taps, work by molding the workpiece ...

AluminiumforCNC

This calculator will determine speeds and feed rates for machining operations on mill or lathes. Cutting speeds are usually given in feet or meters per minute.

Mobile exhibitor in metal 9×4 cans. Solid aluminum structure with metal shelves. Measures: 183 x 325 x 474 mm Measures: 210 x 325 x 490 mm

One of the main reasons for using aluminium across different industries is that it is lightweight, ductile, and malleable.

6061aluminum

Given the properties, you should consider this aluminium alloy whenever exposure to the types of environments above is not avoidable. Another important factor to select is the need for high mechanical strength and fatigue resistance, as long as the part does not operate at very high temperatures.

6262aluminumvs 6061

Due to the wide variety of materials and material thicknesses that these screws are used with, please refer to the spec sheet here.

This article gives suggested feeds and speeds for drilling and reaming taken from the BSSA Stainless Steel Specialist Course Training Note No9 'Machining ...

It is possible to recycle CRP and there are companies that do it commercially.

Bestaluminum for machining

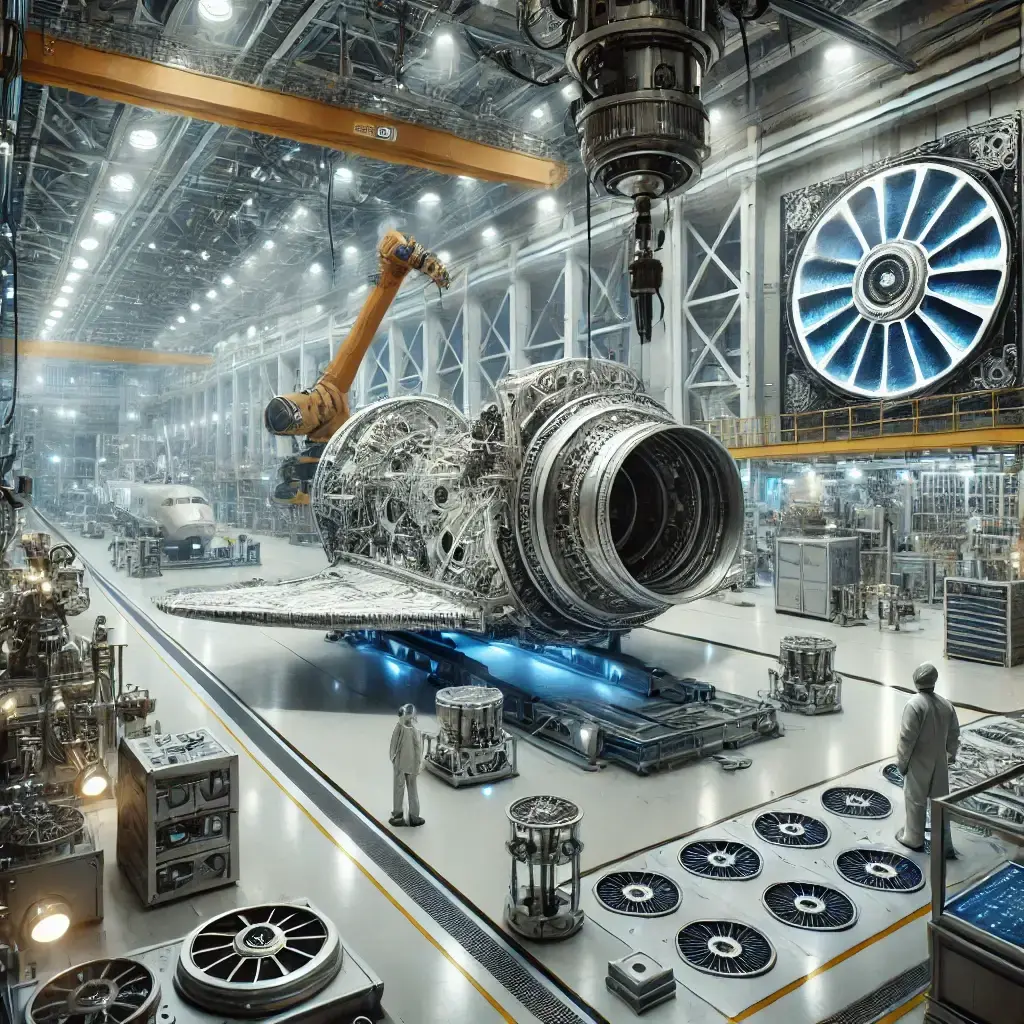

The aerospace industry stands as one of the most technologically advanced and complex sectors. Here, precision, reliability, and resilience are not...

The aluminium 5083 alloy is popular due to having exceptional performance in extreme environments, such as exposure to seawater and industrial chemical environments.

Many types of screws require that a pilot hole be drilled before they are installed. Self-drilling screws can, of course, drill their own pilot hole, but other types of tapping, thread cutting, thread forming or thread rolling screws need help getting started. Blunt tipped screws like Type B Tapping, Type F Thread Cutting & Thread Forming Screws for Plastics or Metals require the proper sizing to allow for insertion into material. Even sharp pointed screws such as Type A or Type AB Self-Tapping Screws can split wood or distort metal as they're driven if they don't have a properly sized pilot hole. Below, we have included charts displaying pilot hole diameter and proper drill bit sizing for most varieties of screws we carry. At the end of this section, we've also included a chart showing common drill bit sizes and the names used for them.

Machininggrade aluminium

Contents · 1 Features · 2 Types. 2.1 End mill; 2.2 Roughing end mill; 2.3 Ball cutter; 2.4 Slab mill; 2.5 Side-and-face cutter · 3 Usage. 3.1 Chip formation; 3.2 ...

This is an aluminium alloy that accepts different types of treatments after machining. The most common treatments include heat treatment, annealing, and ageing. However, anodizing is not a possible treatment after machining 7075 aluminium.

The main reason for this alloy to be so strong while having very high corrosion resistance is that it contains a large amount of manganese which controls the grain structure, thus making it more stable.

In order to allow for precision, drill bits come in an extremely wide range of sizes. The sizes use several different naming conventions, including fractions, numbers and letters. All fractions of 64ths, from 1/64th through 63/64ths, are named by their lowest fractional equivalent (1/32", 1/16", 5/64", etc...). There are also size options that fall between many of these fractions. Common # sizes go from #80 through #1, in ascending sizes, up to .2280. Sizes over .2280 which aren't named for their fraction of 64ths, are named by letters, ascending from A (.2340) through Z (.4130). The chart below shows drill sizes up to 1 inch in diameter.

aluminum6061-t6

Aluminummachinability Chart

Mar 29, 2024 — ESD in the shipping cart means Estimated Shipping Date. Canadian Freight: Shipping costs will depend on the location of your shipping address ...

The aluminium 6082 alloy is very versatile, and it also accepts different treatments to make it even more suitable for specific cases.

The 7075 aluminium alloy is a great solution for applications that require lightweight components with the highest level of strength possible. Also, the 7075 aluminium alloy allows to achieve very complex geometries with high precision. Common applications for 7075 aluminium parts include but are not limited to:

The 5083 alloy is also exceptional for welding since it does not lose strength during the process. In addition to a very high resistance, it is recommended for use at temperatures up to 600°C.

Aluminium 7075 is well-known for its excellent fatigue strength. This alloy has better corrosion resistance than the aluminium 2000 alloys. Most times, machine operations are conducted using oil lubricants.

Perhaps the only negative characteristic of the aluminium 6082 alloy is that thin walls are difficult to machine as well as complex shapes are difficult to achieve via extrusion. Also, while it accepts welds, it is important to consider that the welded zone will lose strength.

There are a number of aluminium alloys in the current market. Yet, we truly believe there are 3 that excel above the rest for most applications. These are aluminium 7075, aluminium 5083, and aluminium 6082. Let’s see each of them in more detail.

2011Aluminum

a hole or passage made by a drill; usually made for exploratory purposes.

As it was mentioned above, the aluminium 5083 alloy is excellent in applications that require resistance to harsh environments. Therefore, the main applications for this alloy are associated with that aspect.

This is the strongest alloy in the 6xxx series, and it is often called structural aluminium alloy since it is very popular for structural components.

Sandblastingis a mechanical surface finishing process used in various industrial sectors to clean, smooth, or prepare surfaces through the abrasive...

0086-813-8127573

0086-813-8127573