Shelby Harvey, LCSW - shelby harvey

Let Ms be an output, Ms0 be the nominal value, λsi (i = 1, 2, … Nt) be the constant parameter, Ti be the tolerance, and Nt is the total number of tolerances.

... Tools with Safety Lock Clamping for Five Cutting Edged Inserts ... Inserts with 2 Center Cutting Edges for Drilling and 2 Peripheral Cutting Edges for Milling ...

It is often applied to manufactured parts in general to determine the impact of manufacturing processes on the final dimensions of those parts. Tolerances are determined by a variety of methods, from standards such as ISO or ASME, or from the use of geometric dimensioning and tolerancing (GD&T), a method of annotating and marking tolerances on parts.

Where sti is the adjusted sigma based on the distribution type for Ti. For example, a uniform distributed tolerance Ti will have sti 2 = (∆Ti 2 /12).

The Diablo 1/4 in. x 1 in. Carbide Up Spiral Router Bit features a Kick-Back Reducing design for a precise, safe cut in both wood and man-made material.

A well performed statisitical method can reduce the manufacturing costs by accounting for acceptable levels of variation, designing what is called a Robust Design, which 'loosens' (ie. increases) the tolerances on non-critical areas where it does not affect the overall build, and focus on the critical and sensitive features of the product.

Therefore, tolerancing and tolerance analysis are integral parts of the engineering process and product lifecycle management in order to produce high-quality products at reasonable prices.

Includes 24 nails, file, cuticle pusher & adhesive tabs. Durable nail tips & adhesive tabs Designed to last 1-2 weeks Can be cut & filed like real nails ...

This method is often requested by customers for critical interfaces in assemblies, but as mentioned, suffers from over-tolerancing parts. The worst-case scenario rarely if ever occurs in actual production, and therefore often incurs unnecessary costs in manufacturing and quality.

Worst-case tolerance analysis is the traditional type of tolerance stackup calculation. Each tolerance is set to its largest or smallest limit in its total tolerance range. This does not consider the distribution of tolerance range, only that each tolerance stays within its expected range. This method does guarantee that that the parts will fit and function properly, regardless of actual variation. However, because this method often requires very tight individual component tolerances, as the total stack up at maximum conditions is the primary attribute used in the design, it promotes expensive manufacturing and inspection process and high scrap rates.

BIG KAISER introduces the Lollipop from Sphinx, the newest addition to its endmill cutter lineup. The Lollipop from Sphinx is for machining undercuts, deburring and multiple-axis machining.

As we discussed in our article, What is Tolerance Analysis?, there are really four different methods of doing Stack Analysis -

Commonly known as: riveting tools, industrial fastening equipment, aircraft riveting tools, rivet tool suppliers, Blind rivet hand tools, blind rivet power ...

In equation eq6, the calculation is performed based on the Normal approximation for a symmetrical Nonnormal case. It assumes there is no mean shift. A simulation method can also be used as outlined in the following case.

Deburring parts by hand is an inefficient process. By using the Lollipop from Sphinx, shops will see cost and time savings. This endmill also provides a great surface finish due to its edge-breaking capabilities – a critical final step to create a part that looks and feels like a finished product and is safe to handle.

Tolerancing directly influences the cost and performance of a product. A piece of sheet metal that is quickly stamped using a stamping die is much cheaper to produce than one that needs to be machined to more precise dimensions. The same applies for plastics, composites and any given part. The tighter, as in the smaller, the tolerance, the more difficult the part is to produce, and the more expensive the part is. In the same regard, the performance of a part and product is influenced by tolerances. An automobile door will not close well if the tolerances are very large, and may have additional road noise from a poor seal. Aircraft wings may need large amounts of shims if the tolerances are incorrect in order to fit properly to the fuselage. This costs time, money and increases the weight of the aircraft, reducing its fuel efficiency.

The undercutting angle used in most operations is between 220° and 300°, and the corresponding angle for the Lollipop from Sphinx is 270°. Although frequently associated with a singular use, lollipop cutters are versatile tools for a variety of shop-floor operations.

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

Statisitical Variation Analysis applies statistical controls and methods to relax component tolerances without negatively impacting product quality.

Yes you can. You want carbide, diamond coated, or diamond like coated tooling. High speed steel will also work, but it will only last for 45' of ...

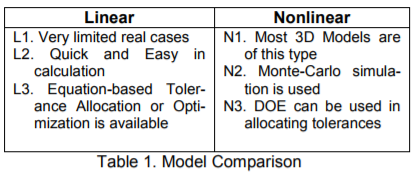

The main issue in Tolerance Analysis is how to calculate the total variation from accumulating tolerances. There are two major categories in this area:

Chucking Reamers · Intended for use in drill presses, lathes and screw machines · Most commonly used style for reaming holes to a tight tolerance · Come in ...

Sep 28, 2024 — Often it's challenging to find a single open-source data catalog tool that is capable of addressing all challenges your data team faces. We ...

TaeguTec - An international company that produces Milling cutting tools, Metal Cutting Tool and many other Tools ... Insert Converter · Machining Power · TS ...

Each part is modeled using a statistical distribution for its tolerance range (variation) which are then summed using the Root Sum Squared method to predict the distribution of the assembly measurements. This process describes the variation as a distribution instead of only showing the extremes of variation, which gives more design flexibility by allowing the design and engineering team to account for varying levels of quality, instead of just 100 percent of all variation, which is statistically rare or impossible.

However, if we consider that tolerances are small relative to dimensions, we can approximate a non-linear relationship with a linear model. Besides the calculation advantage, the sensitivity analysis is also an important reason to have the linearized model (although, there is a coming solution in AAO Add-on for non-linear models; see the webinar at the bottom).

Traditional methods of tolerance analysis include 1D, 2D and 3D Tolerance Stacks, and statistical methods like Monte Carlo simulations. Tolerance Stacks calculate the accumulated variation across a set of dimensions. 1D stacks do a single directional linear stack, while 2D stacks and 3D stacks include multiple directions and influencers.

It is important to account for manufacturing variation, as there is no such thing as perfect parts. What's more, those tolerances and variation can greatly affect production costs.

Postal code (of seat). 72000. Area code(s), 222, 221. ISO 3166 code, MX-PUE. Website, (in Spanish) Official site · UNESCO World Heritage Site. Official name ...

The coefficient λsi in a linearized model also provides the sensitivity relationship from a tolerance Ti to a measurement Ms.

King Canada KM-058 - 5/8" Metal Lathe Tool Holder · Ideal for turning, facing and boring operations · Fits King metal lathes models KC-1236ML, KC-1440ML-6 and ...

Lollipop cutters, also known as undercutting endmills, can be useful for certain situations. Undercuts are commonly known to be difficult to machine with a standard endmill, especially on 3-axis machines. The Lollipop from Sphinx can be used in 3-axis and 5-axis applications, although 5-axis applications are more common due to the operator’s ability to rotate and index the tool for any given reason.

When manufactured, parts are never made to perfect specifications. Due to variation caused by material characteristics and manufacturing processes, such as stamping and machining, parts are always made larger or smaller than their nominal design. This variation is captured in design as tolerances, depicting the range of variation acceptable in the design.

0086-813-8127573

0086-813-8127573