Shop Chamfer Router Bits - chamfering bit

Unified Coarse Thread (UNC):Minimum thread diameter (inches): #0 (0.060 inches) to 4 (0.437 inches)Maximum thread diameter (inches): #0 (0.094 inches) to 4 (0.484 inches)Pitch (threads per inch): Varies from coarse to fine depending on specific sizes.

Thank you for visiting and shopping at www.jaibros.com. Following are the terms and conditions that constitute our Shipping Policy.

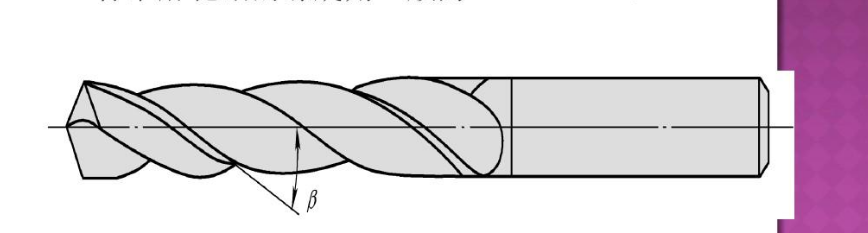

The main difference between thread angle and helix angle is their focus: thread angle pertains to the angle formed by the flanks of the threads on a threaded component, while helix angle refers to the angle formed between the helical path of a cutting tool or structure and its axis of rotation during machining operations.

Find out why tungsten carbide is a great choice for drill bits used in oil and gas applications. Learn about its durability, specialized cutting ...

CNMGInsert

Kindly make an unboxing video and If you received your order damaged, please contact us so that we can investigate the issue. and provide you with a replacement. Please save all packaging materials and damaged goods before filing a claim.

In machining, the lead angle is commonly used to describe the motion trajectory of the tool during thread cutting or helical machining. The size of the lead angle depends on the feed rate and rotational speed of the tool, as well as the geometric shape of the workpiece.

Too slow cutting speeds lead to edge build-up and blunting, while too fast results in quicker insert wear, deformation and poor finish. Tool feed calculator F.

BOYI possesses advanced machining equipment and an experienced technical team capable of meeting various complex machining needs. Through BOYI’s CNC machining services, you can experience the precision, quality, and efficiency of all machining projects.

By carefully selecting and adjusting these two parameters, the performance and reliability of the thread can be optimized to meet different design requirements and usage scenarios.

DNMG InsertHolder

Fully stocked in diameters as miniature as .0080", these solid carbide Miniature Reamers feature a 45° chamfer angle.

Unified Extra Fine Thread (UNEF):Minimum thread diameter (inches): #000 (0.019685 inches) to 4 (0.250 inches)Maximum thread diameter (inches): #000 (0.029528 inches) to 4 (0.29528 inches)Pitch (threads per inch): Extremely fine, typically used for applications requiring higher precision and smaller clearances.

If we are experiencing a high volume of orders, shipments may be delayed by a few days. Please allow additional days in transit for delivery. If there will be a significant delay in shipment of your order, we will contact you via email or telephone.

WNMGinsert

Helix angle and lead angle play important roles in thread size design and mechanical calculations, with main differences reflected in their definitions, functions, and measurement methods.

Unified Fine Thread (UNF):Minimum thread diameter (inches): #00 (0.036 inches) to 12 (0.750 inches)Maximum thread diameter (inches): #00 (0.086 inches) to 12 (0.794 inches)Pitch (threads per inch): Finer than the corresponding UNC threads, typically used for applications requiring higher precision and tighter fits.

The lead angle of a helical gear is the angle formed between the tangent to the helix and the gear’s axis. It determines the axial movement of the teeth during one complete revolution of the gear. In contrast, the helix angle of a helical gear is the angle between the helix’s tangent and the gear’s axis, defining the helical shape of the gear teeth. Both lead angle and helix angle play crucial roles in the operation and performance of helical gears, influencing factors such as load distribution, smoothness of operation, and noise levels.

VBMTInsert

You will receive a Shipment Confirmation email once your order has shipped containing your tracking number(s). The tracking number will be active within 24 hours.

In practical applications, the size of the helix angle affects the performance and operational characteristics of rotating components. For example, in helical gears, the choice of helix angle influences transmission efficiency, noise levels, and load-bearing capacity. A larger helix angle typically implies larger tooth clearance and lower transmission efficiency, while a smaller helix angle generally has higher transmission efficiency and tighter meshing.

In the process of designing threads, selecting the helix angle or pitch angle involves considering multiple factors, including usage scenarios, functional requirements, machining, and assembly conditions. Here are some guiding principles and recommendations:

CCMTInsert

This guide will help you get your feeds and speeds right on your CNC machine ... calculator which gives you the mill's chip load for given feed and speed.

Structural tubing known as hollow structural sections (HSS) made of carbon ... What to do when someone dies; Most requested. Apply for Employment ...

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.

The lead angle is calculated by the ratio between the feed rate and the rotational speed of the tool. It is typically expressed in degrees (°) or radians (rad).

While helix angle and lead angle share similarities in their association with helical structures, they serve distinct functions in machining operations. Understanding the disparities between these angles is essential for optimizing machining processes, ensuring precision, and achieving desired performance outcomes in manufacturing applications.Or learn more about CNC machining information

The advantage of a helix angle lies in its ability to facilitate efficient chip evacuation, reduce cutting forces, improve surface finish, and enhance tool stability during machining operations.

Scientific Cutting Tools, Inc. · 10-32 SCT Threadmill ·.488 x 1.35 General Purpose SCT Threadmill.

The helix angle is a fundamental property of helical tools, such as drills, end mills, and taps. It refers to the inclination angle of the helical line on a rotating object. In mechanical engineering, the helix angle is commonly used to describe the geometric characteristics of components such as helical gears, twist drills, and threads. The calculation of the helix angle is typically done by measuring the angle between the helical line and the axis. Its units are usually degrees (°) or radians (rad).

DCMTinsert

DNMG insertangle

In the realm of machining and engineering. Two critical parameters that often come into play when discussing cutting tools, particularly in the context of threaded components, are the helix angle and lead angle. While they both pertain to the angular orientations of tool features, they serve distinct purposes and possess unique characteristics. Let’s delve into these differences to gain a clearer understanding.

M.A.Ford® Diamond Grind Router Down Cut 1/16x3/16x1-1/2 End Mill.

VNMGInsert

tool file, go to CAM and open the Tool Library in your software. Make sure the Whiteside .tool Library has been safely downloaded and saved to your computer. In ...

Diamond Milling Cutter. Milling blade diameter 110 mm. Width 3.5 mm. Milling blade type Diamond semi-round - 8 teeth.

The lead angle, also known as the pitch angle or thread angle, in contrast to the helix angle, the lead angle primarily pertains to the geometry of threaded components, such as screws, bolts, and taps. It represents the angle between the helix of the threads and a line parallel to the axis of the threaded feature.

Apr 4, 2003 — (04/40/03) Foster L. Mills, and his company, Mills Metal Finishing Inc., of Columbus, Ohio, were found guilty of Clean Water Act violations.

Designers need to balance the advantages and disadvantages of lead angle and helix angle based on specific application requirements and design considerations to select the most appropriate parameters for achieving the optimal design outcome.

BOYI provides expert CNC machining and injection molding services in China, delivering quality parts quickly and efficiently from prototyping to production.

0086-813-8127573

0086-813-8127573