Shop Online with Grocery Delivery | Harveys Supermarkets - order harveys online

Circular interpolation in cncpdf

Adapted from 1) “CNC Language and Structure ” by LamNgeun Virasak, Manufacturing Processes 4-5 is licensed under CC BY-SA 4.0; and 2) “CNC G Code: G02 and G03” by ManufacturingET is licensed under CC BY-SA 4.0

Circular interpolationprogram example

Like the G01 command, G02 and G03 require a feed rate (F). The feed rate will default to the previous feed rate in the code.

When the G02 or G03 mode is in the code, arcs are defined by identifying their two endpoints. The endpoints are easy. In the program, the first point (location or position) where GO2 or G03 is used identifies the first endpoint. The first point begins the circular cut to make the arc on the part. The second endpoint uses XYZ coordinates. The second endpoint is where the arc stops.

Circular Interpolationprogram example PDF

Superabrasive, diamond plated tools have a major edge over carbide—longevity and cut-rate set diamond tools apart from the rest. Initially, a diamond tool will cost more money, but this investment goes toward the extended life of the bit.

There are two different ways to program a G02 or G03. For this class, we will only talk about and practice one of them, which is the I, J, K Method.

Circular interpolationFanuc milling

Circular interpolation in cncexample

Our guide will help you understand the difference between diamond core bits and carbide in depth so you can find the right tool for your job.

The code above will produce the following toolpath. Notice the value for J (the distance in the Y axis) would be zero. It can be omitted.

Circular Interpolationformula

Also like G01, the G02 and G03 codes need coordinates (X, Y, and/or Z). However, the CNC code uses different letters to identify the center of an arc.

Additionally, diamond tools have a closer cut tolerance than carbide does. When used in a cutting capacity, such as a diamond hole saw, diamond tools sand and erode the work material. The smoothing effect of diamond tools allows for high tolerance cuts that are exact. A higher thermal conductivity is another hallmark of the diamond tool. They stay cooler longer and better dissipate the heat created by friction. This means they won’t burn the workpiece and damage it. You can even use diamond tools without coolant and they still won’t overheat. This is valuable in keeping the workshop clean and free of slipping hazards.

circular interpolationi j k

A few factors will help you determine if you need a diamond or carbide core bit. Not the least of which is what kind of material you want to cut. To cut and grind hardened, super-dense materials, such as granite and concrete, you’ll want to use diamond. Diamond also works best on most non metallic materials such as fiberglass and composites.

Support for CNC Copyright © by Lisa Hillyard is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

Carbide drill bits consist of metal—they’re either solid tungsten carbide or have tips covered in a tungsten carbide cement. Professionals can use carbide drill bits in many different industries due to their long life and durability. They are more durable than hardened steel bits, but not as much as diamond. As with any metal drill bit, there will always be wear and tear, dulling, and breakage. The good news is you can sharpen carbide bits to extend their lifespan. However, after performing several sharpening sessions, there won’t be any material left. To work properly, carbide tips need coolant to prevent burning and overheating. It is important to note that coolant mixed with the effluent creates a sludge that is messy and needs constant cleaning.

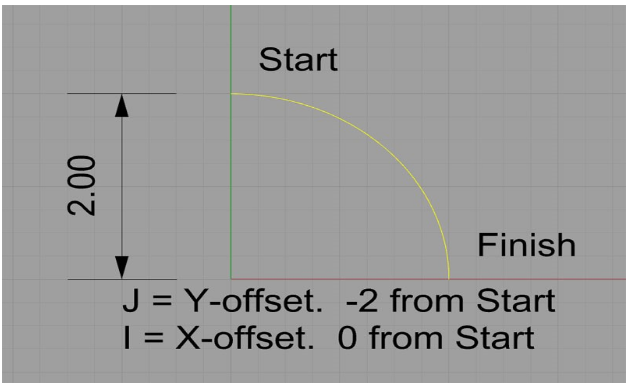

The center point must be equidistant from each endpoint. The center is identified by using I, J, or K to establish measurements (a.k.a. “relative offsets”) from the starting point of the arc to the center. The computer will calculate the starting point to the center. It will compare the center point to the endpoint coordinates. The computer will calculate if those two measurements are equidistant.

The I, J, and K codes identify the DISTANCE from the ARC START POINT to the CENTER POINT of the arc. This distance from the start point to the center point is called “offset.”

Understand the difference between diamond core bits and carbide ones. We cover what each bit can do to remove the risk of buying the wrong one.

0086-813-8127573

0086-813-8127573