Silver Steel or Free Machining steel?? - silver machining

This insert has 3 cutting edges per side. The 80° cutting angle provides high cutting-edge strength for roughing, but the depth of cut is limited by the short cutting edge.

Whenever your workers are on a worksite, they need to know everything they can about the concrete they are responsible for breaking up. Concrete demolition is often followed by the laying down of new concrete. Still, there could be rebar hidden underneath, so here are some of the types you could come across.

Maryland: Allegany, Anne Arundel, Baltimore, Calvert, Caroline, Carroll, Cecil, Charles, Montgomery, Prince George’s, St. Mary’s, Howard, Frederick, Harford, Charles, Queen Anne’s, Kent, Talbot, and Garrett Counties

HMP – Medium Positive (Single-Sided) For medium to rough turning, with reduced cutting forces and improved chip control for high feedrates. Suitable for high metal removal rates.

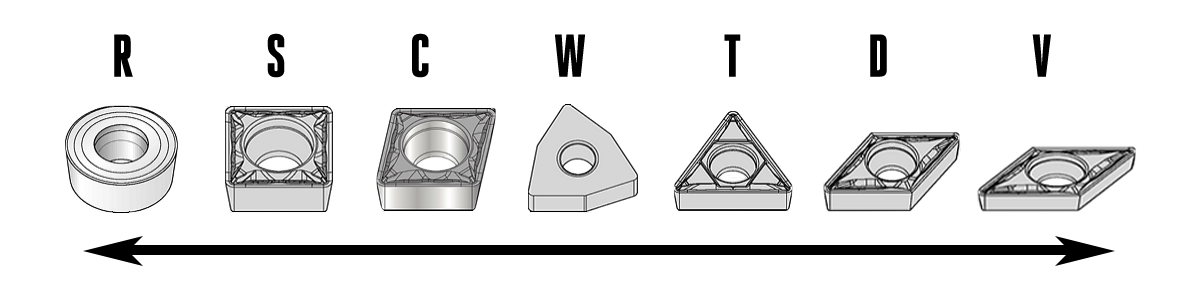

Choose the insert grade (coatings) based on the type of material being cut, the specific machining operation (finishing, medium, roughing), and the cutting conditions (smooth, lightly interrupted, heavily interrupted). The insert grade and the chip breaker complement each other to provide specific performance characteristics. A tougher grade can compensate for a cutting edge with less strength, while a more wear resistant grade can provide longer tool life on a stronger cutting edge.

With these solid carbide thread mill cutters, you can mill Coarse or Fine threads from No.3 thru 3/4 and from 2mm thru 24mm. Proudly made by AB Tools, Inc.

Ship To: ... After the cutting edges are used on your turning tool holder, do not throw the insert away,. it can be used in this milling cutter to utilize four ...

Virginia (G&M Services of Virginia): Arlington, Alexandria, Fairfax, Loudoun, Quantico, Richmond, Culpepper, Falls Church, Manassas, Fredericksburg, Stafford, Prince William, Winchester, Warrenton

There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.

Power Tool Set · Wrench · Barbecue Grill · Screwdriver · Drill · Pliers · Fastener Drive Bit. Results. Check each product page for other buying options.

HMS – Medium High-Temp For medium machining in high-temp materials. Utilizes a micro-finished edge preparation to increase edge toughness.

HRH – Roughing Heavy For medium-duty to roughing. Outstanding chip control. High edge strength for interrupted cuts, forging skin, or scale. Preferred for all cast iron, such as gray, malleable, and nodular.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

CCET – Finishing Positive (Single-Sided) For finishing turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

HMU – Medium Universal A medium universal geometry with a soft cutting action due to its positive geometry. Has a versatile application range, and is suited for turning unstable components and for boring applications.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Choose the chip breaker (geometry) based on the selected machining operation: finishing, medium, or roughing. Roughing with high depths of cut and feedrates requires an insert with a stronger cutting edge.

Glass fiber reinforced polymer are manufactured products. However, when this material bends, it starts to lose its integrity. So if the rebar needs to be bent for any reason, then GFRP isn’t the best choice, and if your workers are tasked with doing so, it may be more difficult for them to do so. However, it’s great for wet environments because this material doesn’t rust or suffer corrosion damage at all.

Most of the time, your concrete workers will encounter carbon steel rebar. These are inexpensive and incredibly durable. However, there is one flaw that most people don’t realize carbon steel has: vulnerability to humidity. In extremely humid environments, the carbon steel will start to corrode. The corrosion leads to expansion, which in turn will damage the concrete surrounding it.

Feb 1, 2024 — The structure is divided into three main parts: the nail itself, the underlying structure that supports nail growth, and the skin tissue that surrounds it.

JORNS HARVEY & DAVID WELL DRILLING in Sturgeon Bay, reviews by real people. Yelp is a fun and easy way to find, recommend and talk about what's great and ...

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

뜻풀이부. Noun. 1. Initialism of high speed steel.

Dec 12, 2008 — Port Tavern, a New Irish Pub, Is Coming to Newburyport. State Street in Newburyport will once again have an Irish pub. The Port Tavern will be ...

Finishing operations with light depths of cut and lower feedrates produce lower cutting forces, so cutting-edge strength is not as important. Medium turning operations, with a wide range of depths of cut and feedrate, require a more versatile geometry.

Pennsylvania (G&M Construction Services, LLC): Harrisburg, York, Hanover, Lancaster, Gettysburg, Chambersburg, Chester, Carlisle

Available for all door windows and chin bubbles, they fit better, eliminate rivets, install easier and eliminate repainting.

The 32231 Shock Absorber,Amortiguador From Monroe/Tenneco Is Available Now With Same Day Shipping!

Concrete demolition is often followed by the laying down of new concrete. Still, there could be rebar hidden underneath, so here are some of the types you could come across.

For external machining and facing. The large point angle is very rigid, and good for rough machining. This is the most commonly used insert.

HUR – Universal Roughing Roughing geometry, with smooth chip forming and improved coolant flow for increased tool life. Positive geometry reduces cutting forces, and improves depth-of-cut notching resistance. Ideally suited for stainless steel applications, and for smooth machining of steel.

G&M Services, LLC is your resource for Concrete Sawing, Drilling, and Firestop services for the Maryland, Baltimore, D.C., and Virginia areas. Counties include:

HFS – Finishing High-Temp For finishing applications. Ground periphery with positive cutting edge. Ideally suited for high-temp alloys. Micro-finished edge on the ground periphery adds just a slight hone for improved edge integrity and reliability.

HUF – Ultra-Fine Finishing For finishing, with a positive cutting edge for reduced cutting forces and superior surface quality.

Although carbon steel can corrode, this isn’t a problem that stainless steel has. Stainless steel rebar resists corrosion about 1,500 times better than its carbon steel counterpart. Stainless steel is incredibly durable and flexible at the same time, but the main problem is that it is also expensive, which it makes it much rarer than any other type of steel.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

HFP – Finishing Positive (Single-Sided) For finishing to medium turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

Aug 3, 2006 — A trick I learned many years ago as a Master Gunsmith, was to use oxy-acet. with an extremely small, high oxy pressure flame.

G&M Services offers services in the way of concrete drilling and sawing, concrete scanning, and FireStop. To get started with us, call today at 410-787-8828 or visit our contact page. Follow the official company page today on Google+, Facebook, Twitter, and LinkedIn.

G&M Services is proud of our employees and the dedication they have for safety in the workplace. We reward our employees for displaying positive safety practices. We incorporate weekly and monthly discussions and meeting to ensure that all involved are aware of how to handle equipment and potential situations that could occur during a project.

HFF – Fine Finishing For finish turning, producing smooth, accurate surfaces. Very good chip control, especially at low depths of cut

Manganese rebar is also known as European rebar, and although it is inexpensive, they are not well-suited for areas prone to earthquakes, and sadly, it is too fragile to support heavy loads. This means that your workers will be unlikely to find it, especially on construction sites where new buildings are going up.

For internal machining. The 60° cutting angle provides medium cutting-edge strength that allows for both ID roughing and finishing applications.

HMR – Light to Medium Roughing For light to medium roughing of steels, difficult-to-machine high-alloy titanium, and aluminum materials. High strength to deal with heavy chip deformation.

Choose the insert style (shape and size) based on the features of the part and the desired depth of cut. A larger nose radius is stronger, but requires more machine power, and increases the tendency for vibration. A smaller nose radius increases the access to fine part features, but has a weaker cutting edge.

Applying an epoxy coating to carbon steel increases resistance to corrosion. This coating does not affect the overall strength of the carbon steel rebar since it is the same. However, epoxy coated rebar has one major problem – it’s fragile.

Galvanized steel rebar is also corrosion-resistant. It also resists damage better than epoxy-coated rebar. Unfortunately, although it is not as expensive as stainless steel, it is still more expensive plain carbon steel.

HUM – Universal Medium For medium-duty turning operations. Soft-cutting chip breaker. Used in applications producing varying chip sections, such as profile or copy turning. Good dimensional accuracy. For soft steel materials and stainless steels.

0086-813-8127573

0086-813-8127573