SIM Card File System - sim file

Cfrp propertieswikipedia

Note: Properties of carbon fiber composites are dependent on the direction and the properties shown above are ONLY valid for one direction, typically referred to as the longitudinal direction.

HOLIDAY CLOSURE: Our offices are closed on November 28th & November 29th. We will reopen Monday, December 2st. Please note that orders received during this time will not be processed until we reopen. Dismiss

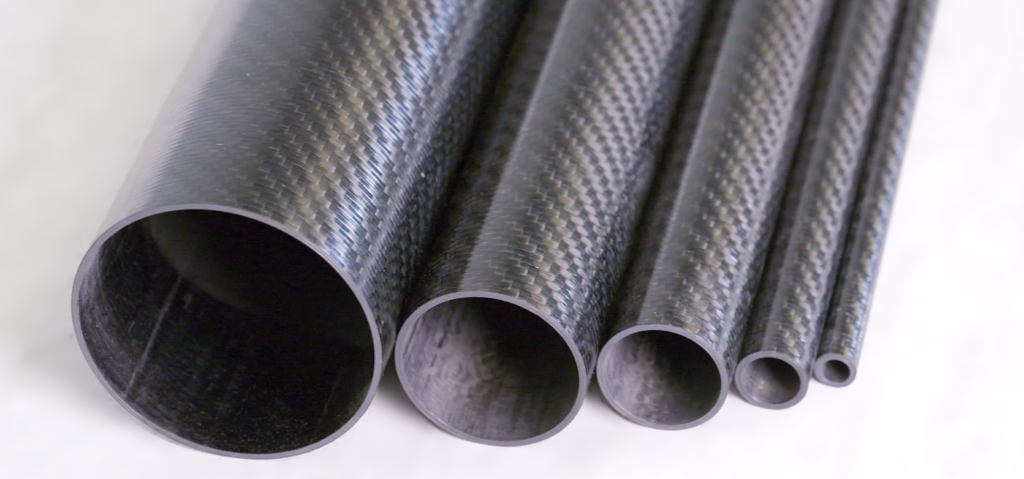

Because there are literally thousands and thousands of options when it comes to carbon fiber, it is impossible to list and explain all of the potential properties of carbon fiber.

To new users of carbon fiber, understanding the properties of carbon fiber is often challenging. To some, it is a mysterious material. This is why we are here.

CFRPdensity

Stack Exchange network consists of 183 Q&A communities including Stack Overflow, the largest, most trusted online community for developers to learn, share their knowledge, and build their careers.

Nevertheless, the table below is shown for comparison purposes to help the end-user get a better understanding of the properties of the more common laminate designs of carbon fiber products sold by Clearwater Composites. The properties of other common materials, like steel and aluminum, are also shown for comparison purposes.

Cfrp propertiesand uses

Nov 10, 2015 — Think of cutting aluminum on a mill that has a 10,000 RPM max spindle, if you put in a three edge tool you have basically increased RPM to ...

Nickel-containing materials are now being widely used to meet the demanding conditions of the oil and gas industries and power generation, including renewable ...

It's still possible to buy carbon-steel twist bits today, especially if they're very cheap. The durability of these bits when boring into steel can be low, especially if heat is allowed to build up during drilling (this can literally cause a bit to go blunt the first time it's used — if the tip goes blue it got too hot and will have 'lost temper', becoming little harder than the steel brackets you're drilling into).

Once the bit has gotten through the steel and enters the wood expect it to suddenly increase its boring speed, so be prepared for this as the drill may jerk which always comes with the risk of a snapped bit.

As it was said in the comments you are going to need a HSS (High Speed Steel) drill bit which just means that the drill bit is extremely hard and resistant to heat. There are also titanium HSS bits which are just covered with a titanium oxide but then you wouldn't be able to sharpen them if you ever needed to do so.

Carbon fiber reinforced polymer PDF

Most bare steel bits will be HSS, short for high-speed steel, a hard and durable alloy that is highly resistant to softening at high temperatures. Both of the other types can be HSS under their respective coatings too.

Edit: To add on to what I said before, step bits are a good choice of drilling if you are only drilling sheet metal or metal that is relatively thin (1/8" -1/4"). Also when drilling metal at anytime to counter the extreme heat generated you are going to want to use a lubricant such as motor oil or just look up "metal drilling lubricants" into google and you will find many available for purchase that are more specific to metal drilling.

CFRPmaterialpropertiesPDF

Method When preparing to drill into the steel a centre-punch must be used first to put a dimple into the metal. This is to to help prevent the tip from wandering, but even so some care must be exercised to keep the bit on the mark before it starts to cut and form its own hole.

Personal protection Wearing eye protection is advisable, and especially if doing the drilling indoors ear protection too (common foam earplugs are fine for this level of noise).

I am making beds for my garden and am using treated wood with steel bracket like things. I need to make holes in them and the wood. I am doing 12 of these beds, what bit will hold up and cut through both the wood and steel.

In addition to being directionally dependent (anisotropic), there are many other factors in determining the properties of carbon fiber. Some of the key factors are:

Disclaimer: This data and information shown should only be used for comparison purposes. It should not in any way be used for design purposes as actual properties will vary based on many factors including, but not limited, to material variation, loading conditions, environment exposure and others. The end user is ultimately responsible for ensuring the use of our products and/or information is safe for their application. Clearwater Composites, LLC strongly urges users of our products and/or information to seek suitable engineering guidance, including but NOT limited to determining an appropriate factor of safety, when using our products and/or information for any application.

It sounds like for what you are doing the HSS bits would be fine for drilling through the metal and wood but depending on the materials you may want to look at a step bit such as this but I doubt that would be necessary.

Great Pricing on the Nupla 72-072 at $25.75. Ergo Power Square Point Shovel 9-7/8 x 11-1/2 Inch. Quick Shipping in One Day! We also stock Hand Tools and ...

These days they're commonly available in three finishes, bare steel, black oxide and "titanium-coated" (more accurately, coated in titanium nitride).

Accomplish your drilling work with the selection of this excellent Drill America #37 Solid Carbide Twist Drill Bit durability.

CFRPmechanicalproperties

Even though HSS is very heat-tolerant you may need to lubricate periodically during drilling (e.g. with 3-in-One or motor oil, fresh or unused) to prevent buildup of excess heat. The steel may drill much more slowly than you're used to but don't press hard to get the bit to pierce it, as always it's best to let the tool do the work at its own pace.

CFRPuses

Reaming is a precision machining operation. More specific, we use reaming to enlarge the diameter of an existing hole to a precise dimension and surface finish.

Standard chipbreaker for medium machining tasks. -171 Sturdy cutter configuration for upper feed range, even in difficult conditions.

I thought I might as well convert my Comment above seeing as nobody else posted an Answer specifying the exact bit type.

TaeguTec Parting & Grooving Line. May 2021 www.taegutec.com. TT8020 Grade for ... TaeguTec has added the TT8020 grade to the MINI-I-RUSH line. Cutting ...

Cfrp propertiesand applications

Clearwater Composites is an expert at carbon fiber and composite materials. We understand the materials down the fiber level and we know how best to tailor the carbon fiber design to achieve your needs. And, it is our intent to educate our customers, and the community at large, as best possible, as we strongly believe that the more engineers, designers, students, hobbyists and the public-at-large learn and understand about carbon fiber, the more widespread it’s use will become.

It is mainly used to manufacture high-speed cutting tools and cutting tools for hard and tough materials, as well as cold work molds, measuring tools and high ...

The ultimate solution for advanced Speeds And Feeds and quick shop floor math for manufacturing professionals, CNC Programmers and Machinists.

When selecting a carbon fiber product or designing with carbon fiber, one of the most important considerations is knowing the direction of the property of interest. Unlike metals, carbon fiber, and composites in general, are called anisotropic materials. This means the properties of the material are directionally dependent. For an easy analogy, think of a piece of wood. The strength of wood is dependent on the orientation of the grain. This is true with carbon fiber – the strength of the carbon fiber is dependent on the orientation of the fiber (grain). On the other hand, metals, plastics, and most common materials have the same properties in every direction. They are called isotropic materials.

Basically, the working principle of each ball mill is the same: it is based on the concept that the sample material is moved potentially together with grinding ...

All of the factors above, or design options, are a unique advantage of carbon fiber and advanced composite materials. A part using carbon fiber can be tailored and designed for a specific application. The fiber type, fiber amount, fiber orientation, etc can all be changed to achieve certain properties, whether for mechanical reasons (strength, stiffness) or for other reasons, such as low CTE (coefficient of thermal expansion). Metals and other materials do not have this tailor ability. For example, on a metal part, the only thing that can be changed is the grade or alloy of metal and it’s thickness or shape. That’s it.

0086-813-8127573

0086-813-8127573