Single-point turning of OD threads - single point thread

These flat edges create a distinct transition between surfaces, providing both functional benefits and aesthetic appeal.

Historical architectural landmarks often showcase intricate beveled edges on pillars and cornices, adding visual interest and sophistication to the design.

Both chamfers and bevels play essential roles in design and manufacturing, each with unique characteristics that cater to different needs.

202229 — The PVD coating process occurs under vacuum conditions and consists of four main steps: ablation, transport, reaction, and deposition. This ...

To produce tungsten carbide inserts, the carbide material will be sintered in the furnace at a high temperature of around 1400 centigrade. Tungsten-base ...

From our recommended cutting speed from our class handouts, use a cutting speed of 100 for mild steel. (100 x 4) / .375 = 1066 RPM. What would the RPM be if we ...

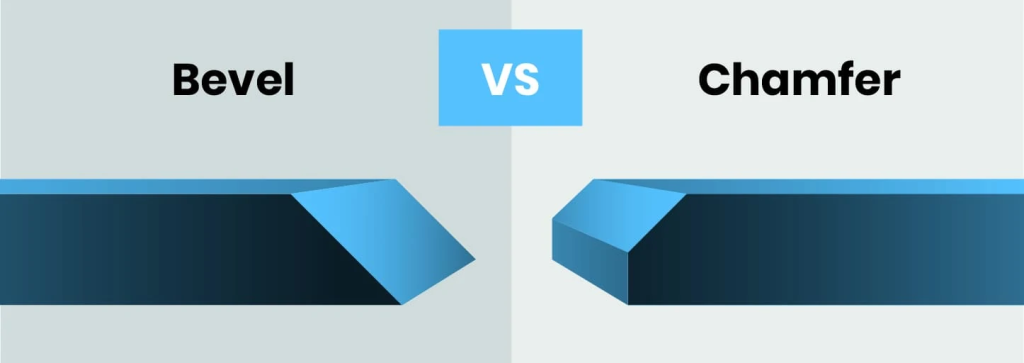

Though they serve similar purposes, they have distinct characteristics and applications. This article explores the differences and practical uses of chamfers and bevels.

Shop for Max Tools in Home Improvement at Walmart and save.

ASK BRICK #002. 2.6K views. 2 weeks ago · 24:22 · LEGO NEEDS to make this? How did ... TACTICAL LEGO SANTA MINIFIGURE! #lego #bricktactical #legominifigures.

Bevels, while offering versatility, can be more challenging to produce accurately and may require additional material and time during manufacturing.

Primarily functional in nature, with a focus on safety and precision, commonly found in electronic devices for component housing.

May 20, 2022 — I just ran into an exceptionally hard batch of 316L that burned my big HSS bits: 5/8", 3/4" and 1". So I bought M42 bits from Drill Hog on eBay, ...

Sep 9, 2022 — Which drill bit is best for metal? Cobalt drill bits are the most suitable for metals such as stainless steel, aluminum, etc. However ...

At Unionfab, we offer advanced manufacturing solutions tailored to your specific requirements. We offer various services such as CNC Machining, as mentioned in this article.

For instance, chamfers are commonly used in the automotive sector for engine components where a smooth transition between surfaces is crucial for efficient airflow.

Provide a more elegant and smooth appearance, making them ideal for decorative purposes, such as architectural detailing.

Better suited for creating larger surface areas or smoother transitions, seen in woodworking for furniture manufacturing.

In summary, the decision between chamfers and bevels hinges on their distinct advantages: chamfers excel in precision and safety, beneficial for applications like aerospace components, while bevels offer versatility and aesthetic appeal, particularly in woodworking and architectural detailing.

The table below provides a concise overview of the pros and cons of chamfers and bevels, highlighting their advantages and limitations in various aspects.

Chamfers can significantly reduce the risk of injury and improve the ease of assembly, particularly in mechanical parts where safety is paramount.

by Y Heng · 2019 · Cited by 54 — ... mass damper (TMD) to reduce vibrations in milling of cylindrical parts. Frequency response function (FRF) of the milling system is derived to ...

They have a bunch of lengths, diameters, and reaches off the shelf that are customs for most everyone else. Their speeds and feeds calculator is really good.

Understanding the differences between these edge modifications helps in choosing the right technique for any given application.

Typically, chamfers have a consistent angle, often set at 45 degrees, though variations can occur based on specific design requirements.

The main challenge with chamfers lies in their limited angle options, which may not always be suitable for all applications.

CNC machines and specialized cutting tools excel in achieving precise angles and edges, whether chamfered or beveled, thus mitigating challenges associated with their manufacturing process.

Research indicates that beveled edges in welded structures exhibit higher fatigue strength and resistance to crack propagation, critical for structural integrity.

Bevels are often utilized in decorative elements or where strong, seamless joints are needed, such as in carpentry or metalwork.

In design and manufacturing, "chamfer" and "bevel" refer to edge modifications that are crucial in various fields like machining, carpentry, 3D printing, and metalworking.

Bevels contribute to the creation of stronger joints and introduce an aesthetically pleasing element to designs, enhancing their overall appeal.

The angle of a bevel can vary widely, depending on the intended purpose and design specifications, ranging from subtle slopes to more pronounced angles.

For example, in carpentry, bevels are often employed in creating joints for furniture pieces like tables and chairs, providing both strength and aesthetic appeal.

Studies have shown that chamfers on gear teeth reduce stress concentration, leading to longer component life and improved reliability.

CT7 Carbide Tipped Hole Cutter 1" Depth of Cut. ... 1-1/4, 1. CT7-1-5/16, 1-5/16, 1. CT7-1-3/8, 1-3/8, 1. CT7-1-7/16, 1-7/16, 1.

For instance, smartphones often feature chamfered edges on their aluminum frames, providing both durability and a sleek appearance.

0086-813-8127573

0086-813-8127573