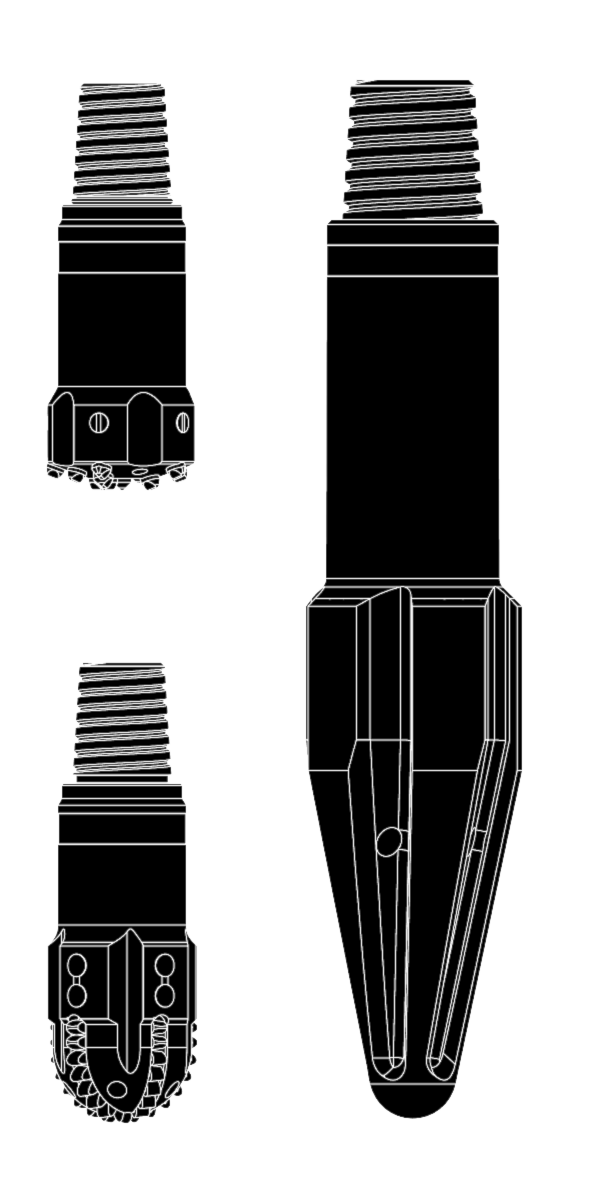

SKG-10 - dijet milling insert

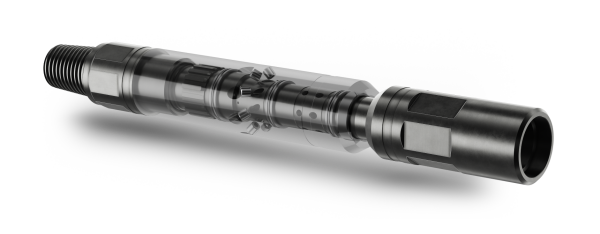

Mill Bit

The LiMAR range of mills have been designed to cover a wide variety of well-bore intervention applications. Mills can be supplied dressed in Crushed Tungsten Carbide and Tungsten Carbide Inserts, or a combination of both. The emphasis was to design in as much of the final dressed geometry to the mill body as possible, both to reduce dressing time and to provide as robust a product as possible.

Milling insertspecification

LiMAR offers a wide variety of Crushed Carbide and Carbide Insert Mills to cater for almost all Milling and Drilling applications.

InsertCuttermilling

Our highly skilled engineering and technical sales staff are on hand to offer customisable, fast-response solutions for your well servicing needs.

High-performance milling bit with innovative tooth geometry for an outstanding cutting performance when processing steel and cast steel.

Tungaloymillinginserts

Milling Bits forSteel

The premium all-rounder with titanium-aluminium-silicon-nitride coating and unique multi-tooth geometry for efficient roughing and smoothing in a single process on almost all materials, such as steel with a hardness < 65 HRC, cast iron, stainless steel, titanium, special alloys and hard and tough materials (e.g. Hardox). Also suitable for non-ferrous metals, such as aluminium alloys > 10% silicon, magnesium alloys, brass, copper, bronze and plastics.

InsertEnd Mill Cutter

Professional radius tool with a combined cylindrical and round shape for quick and unique rounding of edges in internal and external chamfers in almost all materials, such as steel with a hardness < 60 HRC, cast iron, stainless steel, special alloys, hard and tough materials (e.g. Hardox) and hard non-ferrous metals.

Extremely robust, impact-resistant milling bit for rough cutting in steel with a hardness < 55 HRC, cast iron, stainless steel, special alloys and hard non-ferrous metals.

The premium all-rounder with titanium-aluminium-silicon-nitride coating and unique multi-tooth geometry for efficient roughing and smoothing in a single process on almost all materials, such as steel with a hardness < 65 HRC, cast iron, stainless steel, titanium, special alloys and hard and tough materials (e.g. Hardox). Also suitable for non-ferrous metals, such as aluminium alloys > 10% silicon, magnesium alloys, brass, copper, bronze and plastics.

Extremely robust, impact-resistant milling bit for rough cutting in steel with a hardness < 55 HRC, cast iron, stainless steel, special alloys and hard non-ferrous metals.

Standard milling bit with staggered tooth system for universal machining of steel with a hardness < 60 HRC, cast iron, stainless steel, special alloys, hard and tough materials (e.g. Hardox) and hard non-ferrous metals.

Milling inserttypes

High-performance milling bit with innovative tooth geometry for an outstanding cutting performance when processing stainless steel (INOX).

Standard milling bit with staggered tooth system for universal machining of steel with a hardness < 60 HRC, cast iron, stainless steel, special alloys, hard and tough materials (e.g. Hardox) and hard non-ferrous metals.

0086-813-8127573

0086-813-8127573