Slitting saw discount cutter - Nilos.com - slitting saws

© 2024 Toray Composite Materials America, Inc. All rights reserved. All trademarks mentioned are the property of their respective owners in one of more countries.

carbonfibre tensile strength (mpa)

Toray’s MJ and M-series high modulus carbon fibers represent the highest modulus PAN-based carbon fibers available. PAN-based high modulus fibers are superior to pitch-based fibers due to tensile and compressive strengths that are often times more than twice that of a corresponding pitch-based fiber. The MJ series fibers offer enhanced tensile strength and elongation over M series fibers. They are typically used in stiffness and coefficient of thermal expansion (CTE)-critical applications such as spacecraft, premium sporting goods and industrial rollers.

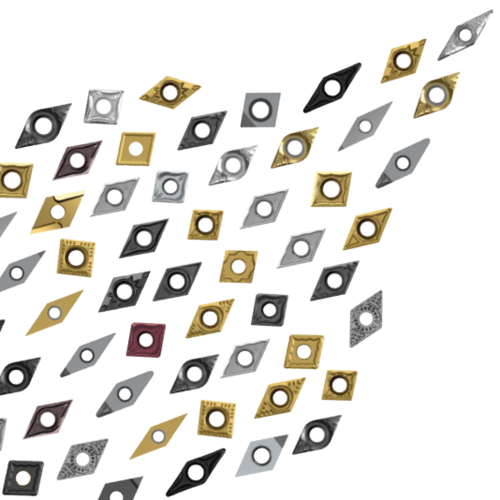

From precision machining of thin-walled workpieces to roughing of large components, ARNO has the optimum indexable insert for every application.

Carbon fiberyield strength

Ideal for long-chipping materials, thin-walled components and optimal surface qualities – high-positive indexable inserts with sharp edge executions from ARNO.

Carbon fibertensile strength

We’re excited for the next 50 years, as we build on our rich history and focus on enabling technology, processability, efficiency, and high-rate manufacturing for our customers.

For perfect surface finishes on steels up to 52 HRC, we also offer a combination of the NFS chip-breaker and AH4205 type.

Carbon fiberPoisson ratio

The tables below show the TORAYCA™ carbon fiber product line available along with some of their properties and a link to the technical datasheet.

Why hard turning? Because it is very efficient, guarantees extreme tool life and excellent surface qualities, and protects the environment. Why ARNO? Firstly, because our coated CBN inserts stand out due to their incredible hardness (up to 65 HRC) and heat resistance, which is achieved via an even distribution of CBN grain and binder as well as a high degree of purity. And secondly, because ARNO offers the optimum solution for every application via seven insert types and two chamfer designs – even for extremely hard materials and the highest cutting speeds.

Carbon fiber modulus of elasticitygraph

While originating as primarily an aerospace material, cost-effective TORAYCA™ carbon fibers are used today in a wide variety of industrial and recreational applications as well. A full portfolio of carbon fiber products is offered, including standard-modulus, intermediate-modulus, and high-modulus fibers with a range of material properties.

Standard modulus carbon fibers typically exhibit a fiber modulus of 33-34 Msi or slightly higher. These are the most cost-effective fibers as measured by tensile strength or modulus per unit cost. Toray’s T300 standard modulus carbon fibers are a recognized industry standard, having been in production since 1971. T700S is a high tensile strength, standard modulus carbon fiber which is another standard industrial fiber. Standard modulus carbon fibers are available in tow sizes from 1K to 24K.

Intermediate modulus (IM) carbon fibers exhibit a tensile modulus of 42 Msi. Originally developed for aerospace applications, IM fibers now find use in recreational and industrial applications as well. Toray offers a broad range of IM fibers with a mix of price and performance characteristics to meet the needs in a broad range of industries. Toray’s IM fibers are available in 6K, 12K, and 24K tow sizes.

Carbon fiber modulus of elasticityvs steel

Carbon fiber modulus of elasticityformula

Ideal for fine machining of high-temperature materials and stainless steels: high-positive indexable inserts with edge-honed executions from ARNO.

If you are looking for a cost-effective alternative for hard turning, look no further – the type AH4205 is ideal for steels up to 52 HRC. Especially when combined with the NFS geometry, this type achieves the highest surface qualities down to RA 0.2 μm with excellent tool life. This is due to the very hard base substrate, a PVD multilayer coating, excellent wear and temperature resistance as well as optimum chip breakage and evacuation.

A comprehensive TORAYCA™ Technical Manual is available with further information that may assist you in selecting the correct carbon fiber product for your specific application some of these include T1100 carbon fiber, High modulus carbon fiber, and intermediate modulus carbon fiber.

0086-813-8127573

0086-813-8127573