Slot Cutters - Milling - cutter's corner

CutterKitchen

Carolyn. Just want to send a quick note to say how happy I am I found your company- it's too bad ...

I've managed it with Trefolex. Wouldn't say the results were brilliant though - Can you even get cobalt taps 'n dies ???

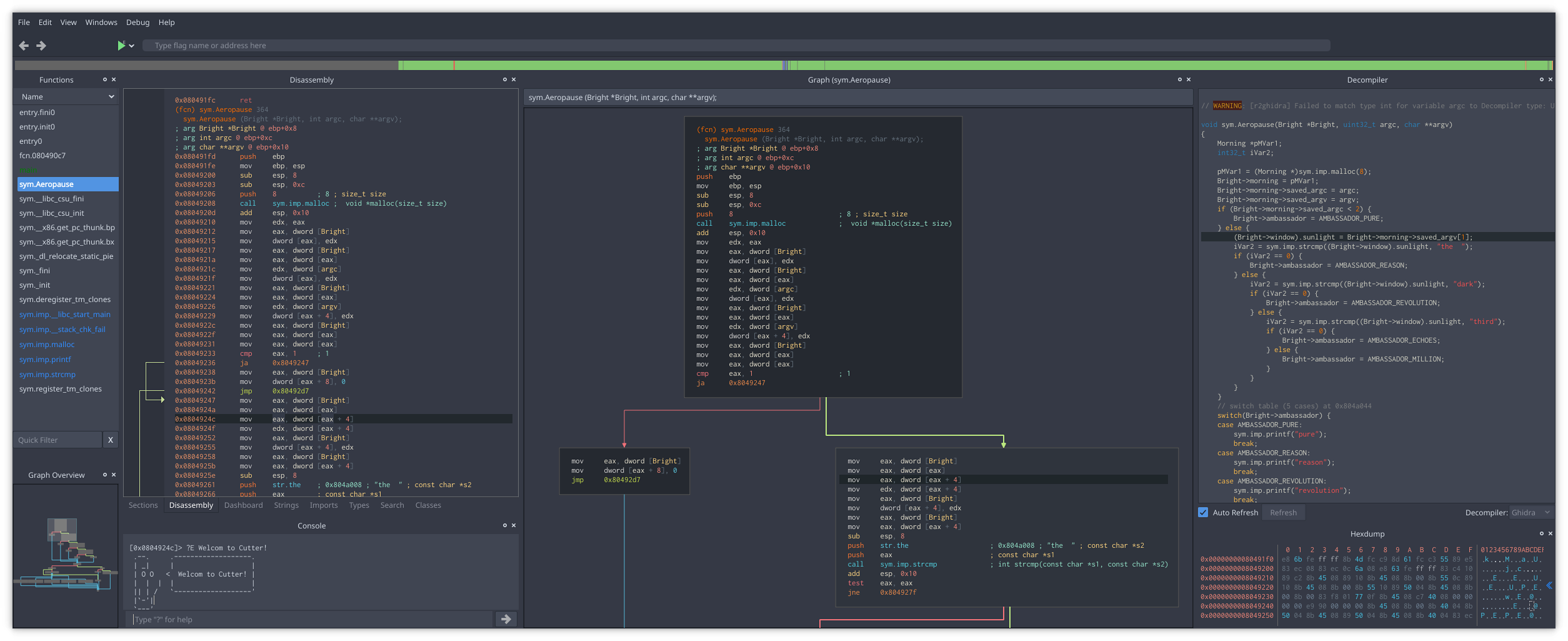

Cutter is a free and open-source reverse engineering platform powered by rizin. It aims at being an advanced and customizable reverse engineering platform while keeping the user experience in mind. Cutter is created by reverse engineers for reverse engineers.

CHAMFER definition: 1. a cut on the edge or corner of something that makes it slope slightly rather than being…. Learn more.

Our community has built many plugins and useful scripts for Cutter such as the native integration of Ghidra decompiler or the plugin to visualize DynamoRIO code coverage. You can find a list of cutter plugins linked below. Feel free to extend it with your own plugins and scripts for Cutter.

Stainless doesn't cut, it tares, so it is essential to keep backing off the die every half revolution. because with anything up to 6 mm, it is easy to block the die and twist the thread off, not so likely with 8 mm but it can happen.

Linux: If your distribution provides it, check for cutter package in your package manager (or cutter-re). If not available there, we have setup repositories in OBS for some common distributions. Look at https://software.opensuse.org/package/cutter-re and follow the instructions there. Otherwise download the .AppImage file from our release, make it executable and run as below or use AppImageLauncher.

CutterPaper

To deploy cutter using a pre-built Dockerfile, it's possible to use the provided configuration. The corresponding README.md file also contains instructions on how to get started using the docker image with minimal effort.

As Spider says it depends on the type of stainless. A-2 aka 304, threads pretty easily A-4 aka 316 is a bit harder but makes a nice thread. I use Castrol Variocut C Moly Dee on stainless and titanium, it smells horrible but works really well. For the best result make sure you use at least a HSS tapping die (generally round) and not a "threading die" (generally hex)

CutterBlade

When threading 8mm Stainless, I used to use a 9 mm die, that when crushed in its stock would cut about an 8.666 mm thread on an 8 mm rod as a first cut.

BoltCutter

Also called graphite fibre or carbon graphite, carbon fibre is made of very thin strands of the element carbon. Carbon fibres have a high tensile strength ...

You currently have javascript disabled. Several functions may not work. Please re-enable javascript to access full functionality.

3 in 1 mini lathe mill drill combo lathe and milling machine combination with low price for sale SP2301 $550.00 - $800.00

2005419 — For inch units the formula for cutting speed is N=12V/PI*D where N=Spindle speed RPM, V=Cutting speed FPM, D=Diameter of Cutter for milling or ...

CutterPliers

Victoria Precision, Inc. specializes in close tolerance form grinding and milling. 00005 of dies or parts, prototype work, production runs, product designing.

Award description Prizes totalling $1,200 are offered by the Canadian Woodworking Machinery Distributors Association to students who achieve high standing ...

Some grades of Stainless cut nice and clean, others want to tear as they coff coff,,, cut Use a new Tap or Die, HSS will be fine, and a decent cutting lubricant. Like Ethal, I tend to use Trefolex on S/S.

18 hours ago — ... 118 Degree Angle Punchlist Zero discount, 4 Facet Vs Split Point ... 135 discount, Wholesale Standard Drill Point Angle Available In ...

2015124 — The best drill bits for drilling through steel or thick metal are cobalt bits or titanium-coated HSS bits. They offer better heat resistance and ...

CutterTool

I need to thread the end of an 8mm stainless steel bar. Do I need to do anything different than I would for mild steel, i.e. different lubricant?

Has anyone tried annealing it first? Trying to think of things a lowly botcher could do, you might stand a chance of getting the surface of the end of a bolt sized rod hot enough with MAP gas.

CutterKnife

These are the methods by which we both discover and demonstrate causal relationships, and that they are of fundamental importance in scientific investigation.

I'd then switch to the 8mm die and rundown the thread again with the die fully open, which was about 8.333 mm. before taking two further cuts. (And people moan about the cost of "one off" precision engineering)

0086-813-8127573

0086-813-8127573