Soap molds, soap cutters and more - CustomCraftTools ... - custom tools

Take a look behind the scenes of our mission: to provide excellent services and proudly present our customers' success stories. Take the time to browse through the lively video reports (click on Vimeo link) and discover how SUHNER becomes a driver of success and satisfaction. Have fun!

a) Material Type: Different materials require different drill bit angles for optimal performance. Harder materials may benefit from a steeper angle to ensure effective cutting and chip removal, while softer materials may require a shallower angle to prevent excessive tearing or splintering.

The point angle for general-purpose drilling is typically around 118 degrees. This angle provides a good balance between cutting efficiency and strength, making it suitable for various drilling applications.

b) 135-Degree Angle: The 135-degree angle is often preferred for drilling hard materials such as stainless steel or cast iron. It offers a more aggressive cutting action, reducing the chances of the drill bit slipping or wandering off course.

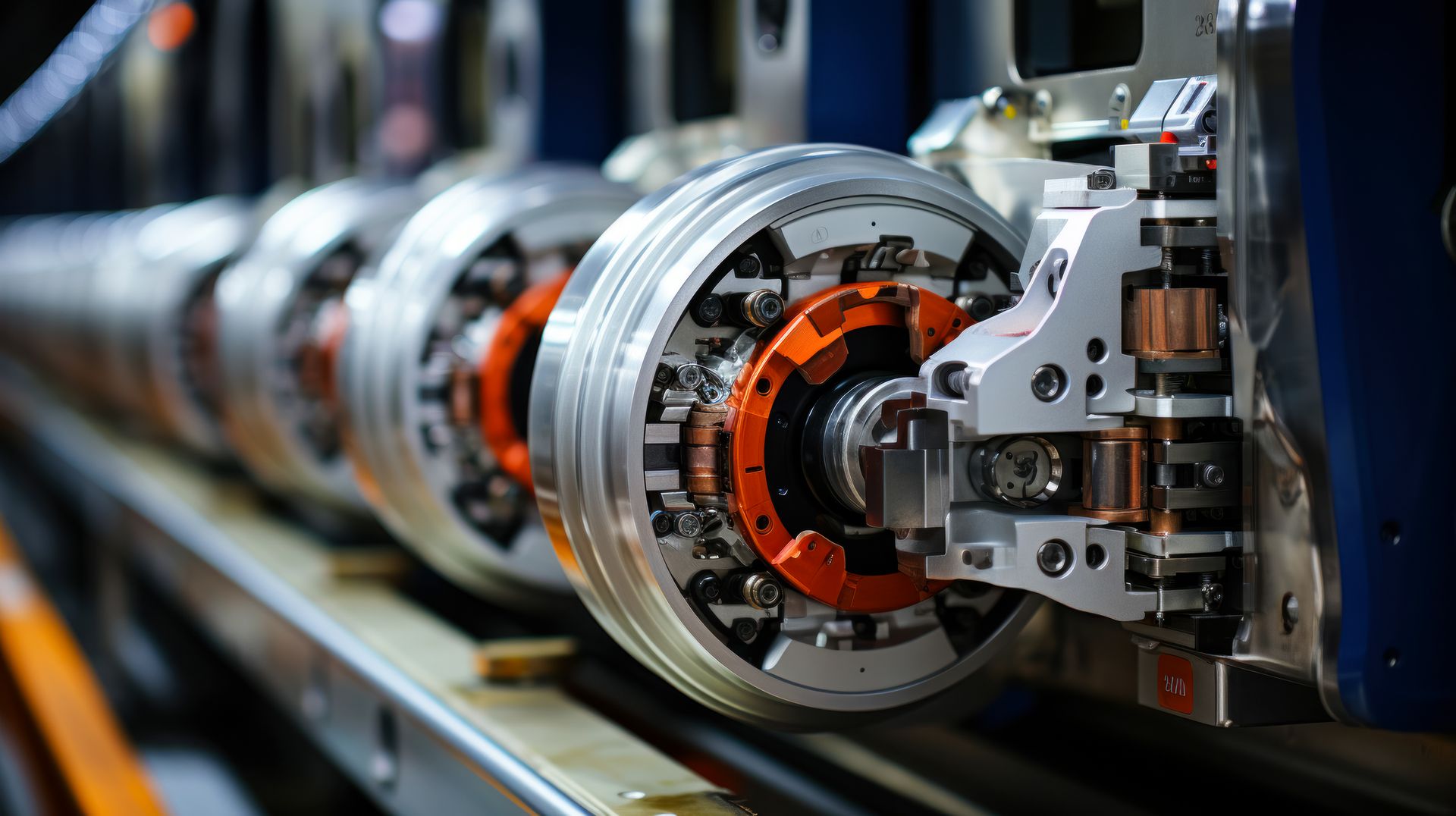

Machining precision mechanical components requires precision, efficiency and technological superiority. SUHNER Machining offers a comprehensive range of precision spindles that multiply your production capacity. Spindles are required for drilling, milling, tapping, boring, cutting and machining ferrous and non-ferrous metals.

The best angle for a metal drill bit is typically around 135 degrees. This angle provides an aggressive cutting action that is effective for drilling through metal.

Our solutions are based on a modular system of feed tables, machine components and drives for relevant machining processes, which are designed and manufactured according to customer-specific requirements. The SUHNER MACHINING Spindles machining units are suitable for the production of various sub-sectors, including

Here at SUHNER, we firmly believe that the voices of our clients are the most authentic ambassadors for our services. Each feedback tells of individual challenges, successful solutions and long-term partnerships. Find out why companies choose SUHNER as their preferred solution partner.

SUHNER offers you access to a comprehensive support network. Our customers benefit from in-depth training, professional service and support throughout the life of the products. Contact us today to find out more about our product range and calculators and how we can help you achieve your production goals!

The choice between a 118-degree or 135-degree drill bit depends on the material. A 118-degree angle is versatile and suitable for general purposes, while a 135-degree angle is

In this article, we will unveil the secrets behind the best drill bit angles. By understanding the ideal angles for different applications and materials, you'll gain the confidence and expertise needed to achieve precise and efficient drilling results.

Numerous renowned car manufacturers and their suppliers rely on SUHNER products. This trust is based on many years of positive experience and SUHNER's constant adherence to high industry standards. Discover the advantages of our products and find out how you too can increase the quality and efficiency of your production. Contact us for more information!

The drill point angle for mild steel can vary depending on the specific application. However, a commonly used angle for drilling mild steel is around 118 degrees or 135 degrees.

To drill a perfect right angle, you can use a drill press with a square or use a guide or jig that ensures perpendicular drilling. Alternatively, you can use a square or right-angle tool to mark the drilling position and align the drill bit accordingly.

It is generally not recommended to drill at an angle unless the specific project requires it. Drilling at an angle can result in imprecise holes and potential damage to the material. It's best to ensure the drill is perpendicular to the work surface for accurate and efficient drilling.

SUHNER Spindles machining units are used for the production of precision mechanical components in large quantities and with high quality requirements. These include applications such as special production machines for the production of precise motor and gear components, sensors, bearings and measuring devices. The areas of application for SUHNER machining units are diverse and specifically tailored to the needs of precision mechanics:

You have just arrived at the testimonials - the place where our customers' stories come to life! Here you can find out first-hand how companies have experienced a successful partnership with SUHNER. Immerse yourself in the fascinating experiences and successes of our customers. These are not just stories, but an expression of our close relationships and shared pursuit of excellence. We are proud to share these inspiring stories with you.

Have you ever wondered what angle provides the best performance for drill bits? Choosing the wrong angle can result in inefficient drilling, damaged materials, or inaccurate holes.

c) 90-Degree Angle: The 90-degree angle, also known as a center drill bit, is primarily used for creating starter holes or chamfers. It is commonly employed in metalworking applications to create precise center holes for further drilling operations.

a) 118-Degree Angle: The 118-degree angle is a popular choice for general-purpose drilling. It is commonly used for drilling into materials like wood, plastic, and soft metals. This angle provides a good balance between cutting efficiency and strength.

"Harder materials may benefit from a steeper angle to ensure effective cutting and chip removal, while softer materials may require a shallower angle to prevent excessive tearing or splintering."

Rely on SUHNER spindles and ensure that your manufacturing processes run efficiently, cost-effectively and reliably. Contact us and use our service to find out more about how precision spindles can transform your production. Switch to SUHNER - for future-proof, high-performance manufacturing.

Drill bits are commonly sharpened at the manufacturer's recommended angle, which can vary depending on the type of bit. For general-purpose drill bits, it is often around 118 degrees or 135 degrees.

Many metal components in vehicle construction are in continuous use around the world, whether in engine and gearbox production or in the machining of load-bearing structures. The spindles from SUHNER MACHINING impress with the following properties:

Drill bits come in various shapes and sizes, each designed for specific drilling tasks. One crucial aspect to consider is the angle at which the cutting edges of the drill bit meet the workpiece. The two primary angles to focus on are the lip angle and the point angle.

The best angle to make a hole using a power drill depends on the material being drilled. For general purposes, a 118-degree or 135-degree angle is often recommended. However, it's important to consider the material's hardness and the manufacturer's recommendations for optimal results.

The core of our strategy is the high flexibility of the SUHNER modular system. The optimum combination of products enables simultaneous completion of machining operations, regardless of the dimensions of the workpiece and the number of machining operations.

In the aviation industry, the precision of manufacturing processes is of crucial importance. Specialised spindles play a key role in producing metal components such as airframes, cabin windows, structural parts, seats and seat rails with a high degree of repeat accuracy. These must be able to perform precise drilling and machining operations that meet the strict safety and quality standards of the aviation industry. Our spindles guarantee:

To set a Drill Doctor to 135 degrees, consult the user manual for specific instructions. Generally, you would adjust the angle guide on the Drill Doctor to the desired angle, in this case, 135 degrees.

Understanding the drill bit angles is a crucial factor in achieving successful drilling operations. Knowing the different drill bit angles and considering factors such as material type, drill bit coating, and drill speed, you can master the optimal drilling angle for each specific application. Remember to refer to the manufacturer's recommendations for optimal performance and experiment to find the best drill bit angles for your needs. With practice and experience, you'll be able to drill with precision and efficiency, regardless of the material you're working with.

Remember, choosing the right angle is crucial for mastering the art of drilling. Let's explore the best angles together!

b) Point Angle: The point angle is the angle between the two cutting edges of the drill bit. It affects the drilling speed and accuracy.

So, if you're ready to elevate your drilling game and unlock the full potential of your projects, keep reading as we delve into the world of drill bit angles and uncover the key to success.

Discovering, shaping and changing together As your partner, we stand for innovation and quality. Let us develop your potential together.

SUHNER spindles are characterised by their precision and durability. The simple handling of our machining units reduces familiarisation times and facilitates day-to-day operation. This leads to a significant increase in productivity and a reduction in operating costs.

To ensure you drill straight down, it's essential to align the drill properly before starting. Use a level or square to ensure the drill is perpendicular to the work surface. Additionally, maintain steady pressure and a controlled drilling speed to prevent the drill from drifting off course.

b) Drill Bit Coating: The coating on the drill bit can affect the friction and heat generated during drilling. Certain coatings perform better at specific angles, so it's important to consider the manufacturer's recommendations for optimal performance.

Discover our specialised spindles for the aerospace industry and find out how SUHNER can help increase your production quality. Contact us for more information and customised advice.

SUHNER spindles are characterised by their precision and durability. Our expertise in development and manufacturing enables us to create products that function consistently and reliably under the most demanding conditions. The simple handling of our machining units reduces familiarisation times and facilitates day-to-day operation. This leads to a significant increase in productivity and a reduction in operating costs.

a) Lip Angle: The lip angle refers to the angle formed by the intersection of the drill bit's cutting edge and the workpiece. It determines the cutting action and helps in chip removal during drilling.

c) Drill Speed and Feed Rate: The speed and feed rate at which the drill bit engages with the workpiece can impact the drilling angle. High speeds with aggressive feed rates may require a different angle compared to slower, controlled drilling operations.

Spindles are critical components in various machines used in industrial manufacturing. They are rotating axes that are usually used to hold tools or workpieces. The main purpose of a spindle is to transmit torque and speed, which makes it an essential component in precision machining, especially in drilling, milling and grinding. Spindles are used in a wide range of applications:

Ready to simplify your processes? Our team is here to support you on your journey to success. Whether it's questions, customised advice or simply an exchange - we're here for you.

Fully Ground Drill Bits:1.0(x3), 1.5(x3), 2.0(x2), 2.5(x2), 3.0, 3.5, 4.0, 4.5, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 10.0, 10.5, 11.0, 12.0, 13.0.

Our spindles are part of an intelligently designed modular system. This system allows you to combine and configure machining units individually and according to the specific requirements of your machine construction. The flexibility of the system allows you to adapt quickly to changing production conditions while optimising the efficiency of your production processes. This modularity is particularly valuable for companies operating in dynamic industries such as aerospace, metal construction and power plant engineering. Find out more about our customised applications:

Your personal contact to success Our solutions are designed to help you unlock maximum value, improve product performance, optimise manufacturing processes and stay one step ahead of the competition in your respective industries.

While the aforementioned angles serve as general guidelines, several factors can influence the optimal drilling angle for specific applications:

Spindles are an indispensable component in modern manufacturing technology. They enable precise and efficient machining of materials, making them a key tool in numerous industrial sectors. Our spindles are designed to offer high speeds and high precision at the same time. They are robustly built to absorb the forces generated during machining and ensure a long service life. The precise alignment of the spindles ensures that the tools or workpieces can be optimally machined, resulting in high-quality end products.

Achieving optimal drilling results requires mastering the best drill bit angles. Without this knowledge, your woodworking, metalworking, construction, or DIY projects may suffer from subpar outcomes, wasting time and resources.

0086-813-8127573

0086-813-8127573