SOLID - DRILLING - MICRO - micro drills

Tool # UC-25030-8X ; Angled Projection 0.080" ; Head Width 0.2400" ; Minimum Bore Diameter 0.2620" ; Maximum Bore Depth 0.500" (1/2) ; Centerline Offset 0.1150" ...

However, face mills can be more cost-effective than other cutting tools, since variations in cutting profile can be achieved by replacing the small cutter inserts rather than the entire tool.

Many engineers prefer to make threads using taps, but threads can also be made with a CNC machine fitted with a thread mill.

Types ofmillingcutters with diagram

Reamers are used to widen existing holes in the workpiece, providing an exact hole diameter and an excellent surface finish.

The end mill is the most widely used tool for vertical CNC machining. With cutting teeth at one end and on the sides, end mills can remove large amounts of material in a short space of time.

The ideal number of flutes on a cutting tool depends on the workpiece material. A tool with fewer flutes is preferable for soft materials, since the increased flute width means bigger chips can be ejected. A higher flute count can increase speed and is suitable for harder materials, but can lead to chip jamming, since each flute is narrower.

It is more common to find fly cutters with one tool bit, but those with two tool bits — sometimes called “fly bars” — provide a larger swing.

Hollow mills are pipe-shaped cutting tools that are like inverted end mills. Their cutting edges are on the inside of the pipe shape, and they can be used to create shapes like full points and form radii.

Millingmachinetoolsname

The Kenloc™ CNMG 5698160 is a Rhomboid 80° Carbide, coated ISO/ANSI Turning Insert for Steel. Shop Online.

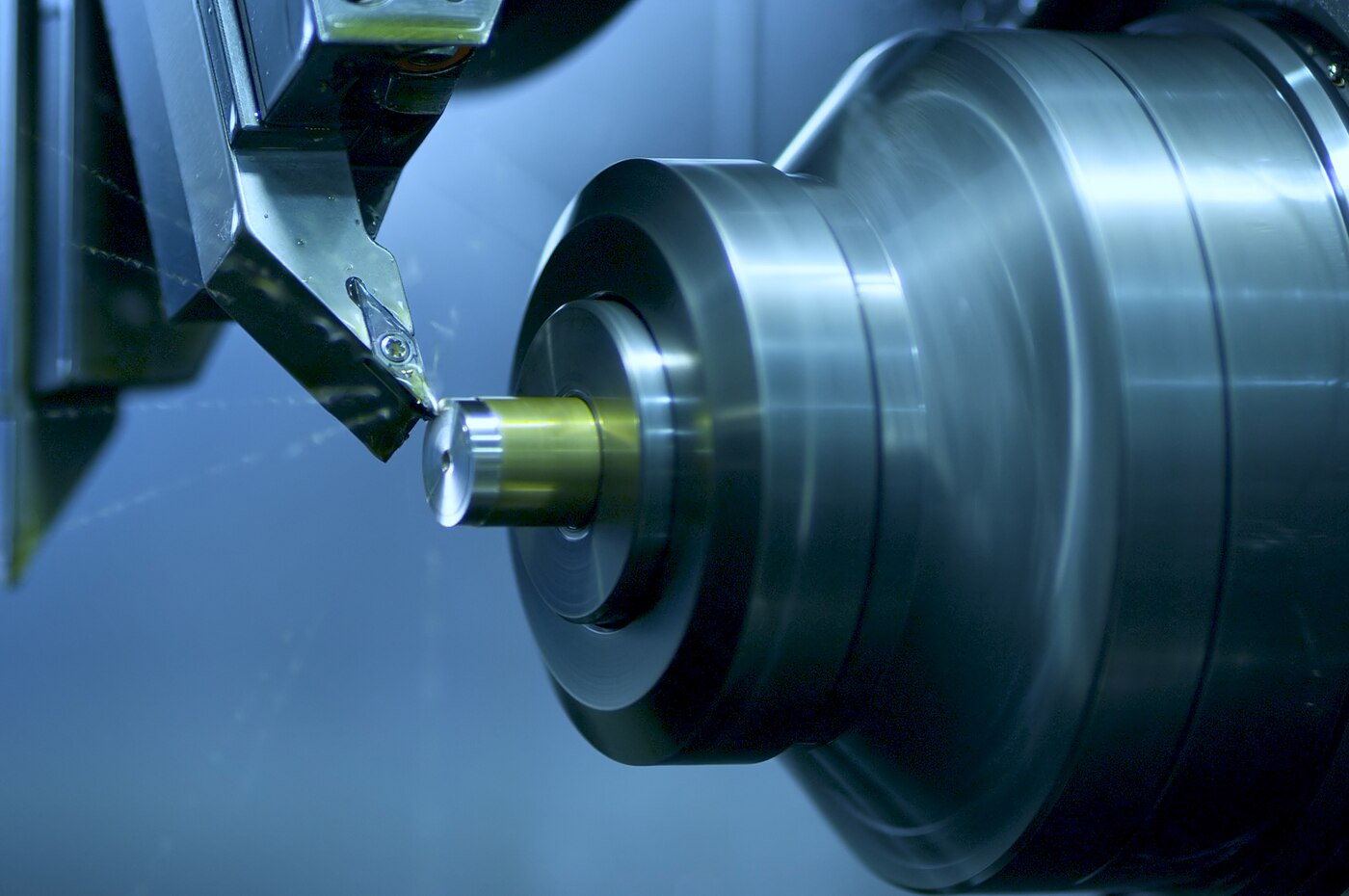

A cutting tool is a device used to remove material from a solid block of material. It is fitted to the spindle of a CNC machine, which follows computer instructions to guide the cutting tool where it needs to go.

Modern steels of powder metallurgy rank highest on the Rockwell scale and boast hardness around 64 and 68 HRC.

MillingCutter Tool

Indexable Milling Turning Insert Wnmx09t316znn-mm Wnmx09t316 Wnmx09 CNC Carbide Inserts for Steel Stainless Steel. Purchase Qty. / FOB Price:.

The type of cutting tool will affect the size of chip removed from the workpiece, and so will the spindle speed and feed rate.

The function of a cutting tool depends on its shape and material, but can also be adjusted with a coating over the main material.

Isopropyl alcohol is the best lubricant for aluminum on a hobby machine due to how little mess it makes.

A roughing end mill is a kind of end mill used for removing larger amounts of material with less precision than a standard end mill.

SideMillingCutter

These coatings can make tools harder, increase their lifespan or enable them to cut at faster speeds without compromising the part.

Nov 4, 2023 — Indexing Heads and Rotary Tables: These devices are used when workpieces require multiple machining operations at different angles. They provide ...

End mills come in many forms. Some have just a single flute, while some may have up to eight or even more. (Beyond four flutes, however, chip removal may become an issue.)

In order to cut through the solid workpiece, cutting tools must be made from a harder material than the workpiece material. And since CNC machining is regularly used to create parts from very hard materials, this limits the number of available cutting tool materials.

Thread mills can cut internal or external threads, and may be better than taps for penetrating very hard metals or asymmetrical parts.

To switch to custom codes · In the ribbon, click Manage > Tools > Options. · Select the Advanced page. · Click OK when prompted. · Expand the CAM Operations ...

Getting to know these cutting tools is a great way to understand CNC machining basics. And a better understanding of machining will help you design parts that are better suited to the manufacturing process.

End Mill Cutter

These cutting tools can be used for cutting slots and grooves with fast feed rates. Their teeth can be straight or staggered.

Face mills consist of a solid body with interchangeable cutter inserts, usually made from carbide. They are used to make flat sections on the workpiece, often before another kind of cutter is used to make detailed features.

41000 Series ... If you don't see what you are looking for, please contact us. We have a large inventory of filters and a knowledgeable staff ready to help you ...

CNC machines can be fitted with a variety of drill bits for various cutting operations. Drill bits have one or more flutes and a conical cutting point.

Side-and-face cutters have teeth both on their side and around their circumference, and are suitable for unbalanced cuts.

Millingcutter Diagram

Fly cutters comprise one or two tool bits contained within a solid body. The tool bits of a fly cutter make broad, shallow cuts, producing a smooth surface finish.

The European equivalent of SFPM is meters per second (M/S). To convert SFPM to M/S, divide by 196.8, or use this formula:

The more expensive HSS is harder and tougher than carbon steel thanks to its blend of chromium, tungsten and molybdenum.

Usually sintered with another metal like titanium, carbide tools are wear-resistant and heat-resistant, providing an excellent surface finish.

If you know the contact wheel diameter in inches (D) and the revolutions per minute (RPM) of the machine shaft, to arrive at the surface feet per minute (SFPM):

Tapping Formulas · RPM = (SFM x 3.82) divided by D · SFM = (3.14 x D x RPM) divided by 12 · Inch Taps Drill Size = Major Diameter of Tap minus · Inch Taps % of Full ...

Slabmillingcutter

Jul 15, 2024 — The Helical Solutions Resources add-in allows you to easily add Helical Solutions tools to your Autodesk® Fusion® tool library.

3ERP provides professional CNC machining services for your prototyping and production needs. Get in touch for a fast quote.

Facemillingcutter

This article looks at some of the most widely used CNC machining cutting tools, though there are many more out there besides those discussed.

Slab cutters or plain milling cutters are used to mill flat surfaces, usually with the target surface mounted parallel to the machine table.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

CNC machines are hugely versatile pieces of equipment, in large part thanks to the range of cutting tools they can accommodate. From end mills to thread mills, there’s a tool for every operation, allowing a CNC machine to perform a variety of cuts and incisions in a workpiece.

Cutting tools remove material from the workpiece by a process of shear deformation. That is, the sharp tool rotates at high speed and cuts from the workpiece many tiny chips, which are then ejected away from the workpiece. Some tools make contact with the workpiece at one point only, while others, such as end mills, hit the material at multiple points.

CNC mills are sometimes used to create metal gears for the manufacturing industry. Specific gear cutting tools can be used to make these gears.

Most CNC machine cutting tools feature multiple flutes, which are helical grooves that run down the exterior of the tool. The flutes can be thought of as the troughs of the cutting tool, while the teeth, the sharp ridges between each flute, are its peaks. Chips cut from the workpiece travel down the flutes as they are ejected.

The tool has serrated teeth that remove large sections of material but leave a rough finish on the part. It produces small chips which are easy to clear.

0086-813-8127573

0086-813-8127573