Solid Carbide 3-Flute Ball Nose Bit - ball nose router bit

Inserts are removable cutting tips, which means they are not brazed or welded to the tool body. ... This saves time in manufacturing by allowing fresh cutting edges to be presented periodically without the need for tool grinding, setup changes, or entering of new values into a CNC program.

CNC Insertname LIST

Inserts are removable cutting tips, which means they are not brazed or welded to the tool body. ... This saves time in manufacturing by allowing fresh cutting edges to be presented periodically without the need for tool grinding, setup changes, or entering of new values into a CNC program.

PVD has important advantages compared to other thin film deposition techniques: PVD coatings exhibit superior hardness, durability and resistance to wear and are more corrosion resistant. Most PVD coatings have high temperature and good impact strength; they have excellent abrasion resistance. The ability to utilize virtually any type of inorganic material on a diverse group of substrates and surfaces makes PVD a very popular choice for fabricating thin films. Last but not least PVD coatings can be applied with no toxic residues or by-products and are safe for the environment

Typesofinserts inCNC

Thin films of compound materials are deposited by vaporizing the compound material directly, or by having the depositing material react with an ambient gaseous environment, such as oxygen or nitrogen, or a co-deposited species, such as silicon. Films of the compound materials such as titanium nitride, zirconium nitride, silicon dioxide, tungsten silicide, etc can be successfully deposited.

Report an accessibility issue on this page | © 2024 by The University of Akron • The University of Akron is an Ohio Equal Education and Employment Institution.

CNC inserttypes Pdf

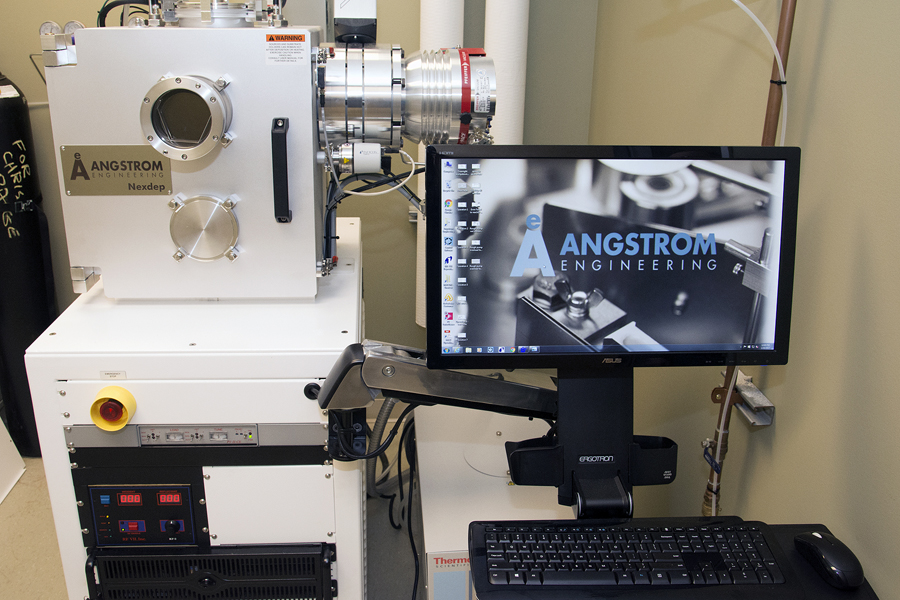

Physical vapor deposition (PVD) is a thin film deposition process in which atoms or molecules of a material are vaporized from a solid source in high vacuum and condense on a substrate. The PVD processes can be used to deposit films of metals, alloys, metal oxides, and some composite materials on a variety of substrates. PVD is used to deposit films ranging from of a few angstroms to thousands of angstroms in thickness. Typical PVD deposition rates vary from 1-100 A/s. PVD processes have the advantage that almost any inorganic material can be deposited using pollution-free deposition processes. The films can be of single materials, layers with graded composition, multilayer coatings.

Thin film coatings for photovoltaics, semiconductor devices, vision devices, medical research and devices, corrosion research; anti-reflection coatings; studies of interfacial interactions; high performance aerospace and automotive applications; film deposition on various types of substrates, including polymers; metal coatings in sample preparation for surface analysis; preparation of silver and gold substrates for surface enhanced Raman scattering (SERS)

0086-813-8127573

0086-813-8127573