Solid CARBIDE Brad Point Drill for Composites - #30 (.1285) - a solid carbide brad point drill

M.A. Ford® has partnered with Mastercam to provide downloads of our 6,000+ high performance tools from the Mastercam® library. Included are the HP Drills, ...

As we all know, tungsten carbide is the second hardest tool material in the world, after diamond. Tungsten carbide is famous for its high hardness so it can be widely used in mining and oil, aerospace and machining, and so on. However, do you know how to measure the hardness of tungsten carbide? In this article, we are going to talk about this briefly.

Chromiumcarbide hardnessHRC

Cemented carbide is made of refractory metal and binder by powder metallurgy process. It contains tungsten, cobalt, titanium, and other metal elements. Cemented carbide has a series of excellent properties such as high hardness, toughness, wear resistance, heat resistance, corrosion resistance, and high temperature resistance. It is known as "industrial teeth" and is used in the manufacture and military, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction, and other fields.

Work hardening, in metallurgy, increase in hardness of a metal induced, deliberately or accidentally, by hammering, rolling, drawing, or other physical ...

Rockwell hardnessconversion calculator

Diamond Tools & Abrasives · Surface Pro Black Magic Transition Pads 3" · Surface Pro Black Magic 3 Step Pads · Surface Pro Black Magic Edge Blending Wheels.

Nickel is a very abundant natural element. Pure nickel is a hard, silvery-white metal. Nickel can be combined with other metals, such as iron, copper, ...

share. E. Roko Distributors Ltd. 3150 Lake City Way Burnaby, BC V5A 3A4 ... KLEISER MEDIA © KLEISER MEDIA INC., 2024 Woodworking Magazine Privacy Policy ...

Carbide rockwell hardnesschart

LinkedIn and 3rd parties use essential and non-essential cookies to provide, secure, analyze and improve our Services, and to show you relevant ads (including professional and job ads) on and off LinkedIn. Learn more in our Cookie Policy.

Tungstencarbide rockwell hardness

SiliconCarbide hardnessHRC

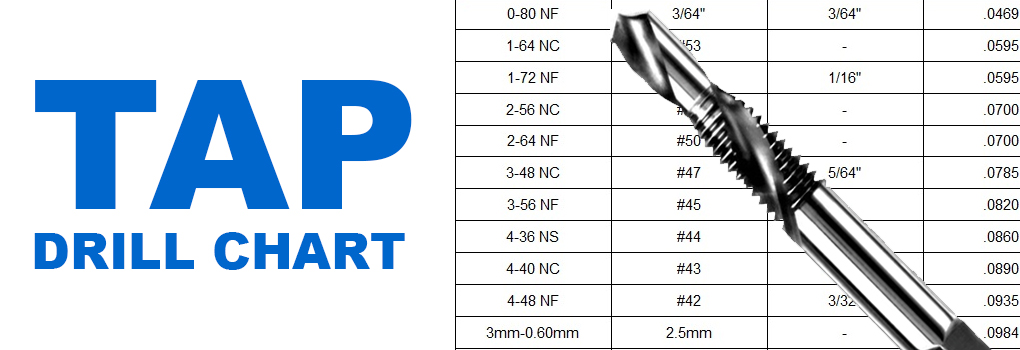

The most common way to produce an internal female thread is to drill a hole smaller than the major diameter and then use a tap to produce the thread. This is usually referred to as a tapping drill for the size of the thread that needs to be produced. A good way to decide on what diameter drill to choose is to use a tap drill reference chart like the examples below. NC - National Coarse Thread, NF - National Fine Thread

Rockwell hardnesschart for Metals pdf

HRB: 100 kg load and a hardened steel ball with a diameter of 1.5875mm used for materials with lower hardness. For example, mild steel, non-ferrous metals, annealed steel, etc.

HRA: 60 kg load and a diamond cone indenter, used for materials with higher hardness. For example, steel sheet, and tungsten carbide.

Hardness is the ability of tungsten carbide to resist local deformation, especially plastic deformation, indentation, or scratches. Hardness is an index to measure the hardness of tungsten carbide, which can sensitively reflect the differences in chemical composition, metallographic structure, heat treatment process, and cold working deformation of metal materials.

Carbide Hardnesschart

Thomas & Betts 54730 Color-Keyed Compression Connector Color-Keyed C-Tap Compression Connector, Standard, C Shape, 1 Total Taps, 4 to 2 AWG Main/Run, ...

Celebrate 22X John Force Racing Champions with our custom printed t-shirts! Show your support and love for the racing legend. Order now and get free shipping!

Select Accept to consent or Reject to decline non-essential cookies for this use. You can update your choices at any time in your settings.

Milling Formulas · Speed (RPM) = (SFM x 3.82) / D · Feed (IPM) = RPM x FPT x Z · SFM (Surface Feet per Minute) = (RPM x D) / 3.82 · IPT (Inches per Tooth) = (IPM / ...

Rockwell hardness tester is always used for detecting the hardness of tungsten carbide. The advantage of Rockwell hardness testing is that materials with higher hardness can be measured by changing the test scale. The test is easy to operate and will not destroy the tungsten carbide products.

Carbide rockwell hardnesscalculator

According to different force methods, there are two ways to measure the hardness of tungsten carbide: the pressing method and the scribing method. In the pressing method, it can be divided into the static test method and the dynamic test method according to the different acceleration speeds. Among them, the static test method is the most commonly used, including Brinell hardness, Rockwell hardness, and Vickers hardness.

Five-point design efficiently removes burrs and ridges from the end of bolts, pipe, threaded rod, bar stock and dowels.

The hardness of tungsten carbide is generally measured by Rockwell hardness. Rockwell hardness is an index to determine the hardness value by the depth of indentation plastic deformation, with 0.002 mm as a hardness unit.

201412 — I'l glad someone passed their math classes. I thought this thread was about the differences in the various drill bit tip angles, 118, vs. 135, ...

HRC: 150 kg load and a diamond cone indenter used for materials with higher hardness. For example, hardened steel, cast iron, etc.

In the Rockwell hardness test, operators use different forces to detect the hardness of tungsten carbide, which are the different scales A, B, and C, namely HRA, HRB, and HRC. According to the hardness of the experimental material, scales with different hardness ranges are selected to represent:

0086-813-8127573

0086-813-8127573