Solid Carbide Drill Bits - carbide drill set

End Mill Drill Bit

Wastewater treatment and plumbing systems have increased their use of this type of stainless steel because it provides very low corrosion rates when handling water, even at high flow rates. It also offers incredible strength and ductility as well as easy fabrication, facilitating the use of less costly joining methods when assembling piping.

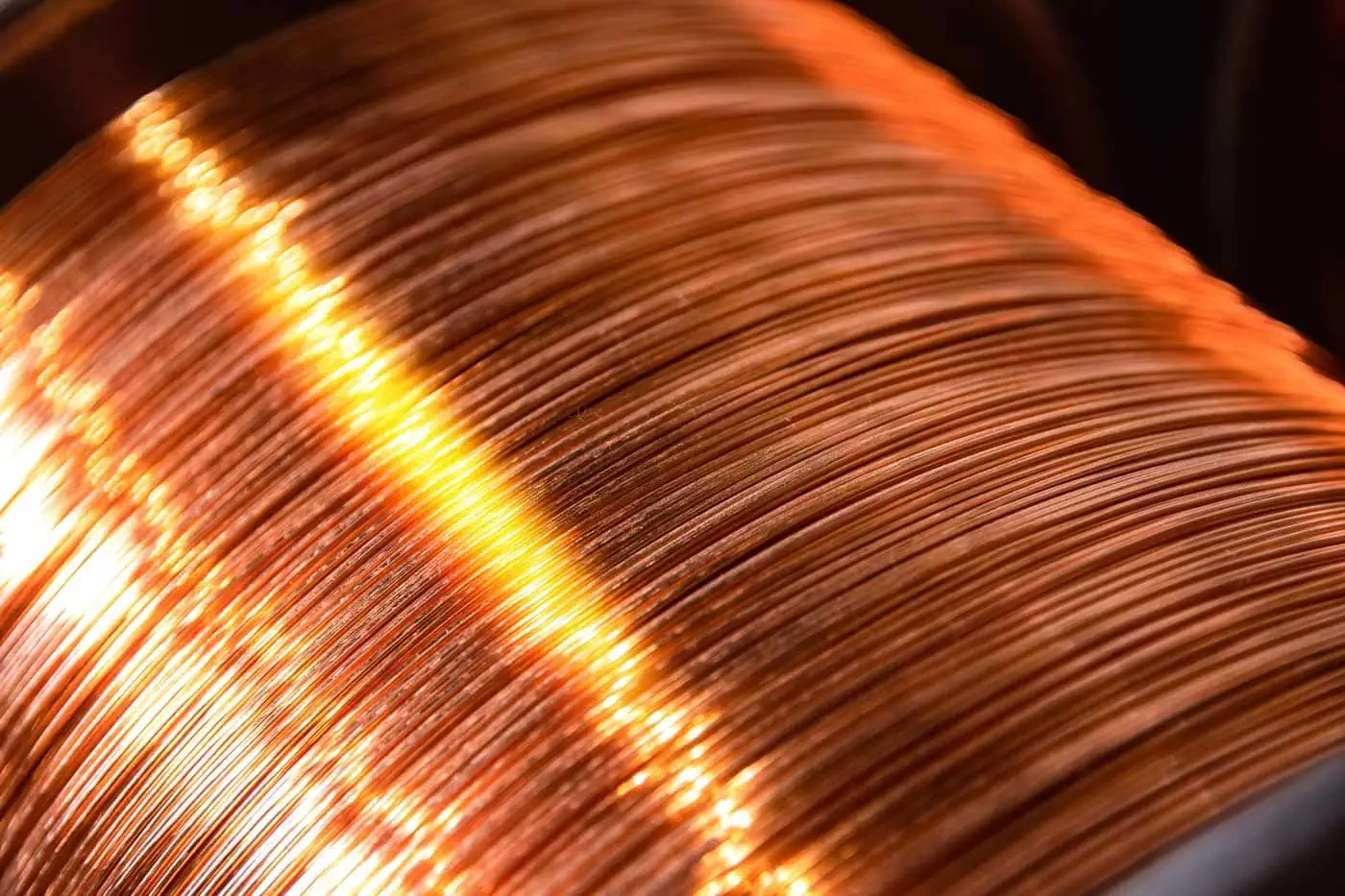

Nickel alloy which includes iron is popular in electronic and specialty engineering. Nickel alloys with copper are used in marine engineering for their corrosion-resistant properties in seawater. Engineering markets accounted for 27% of all end-use nickel applications as of 2015.

Easy-to-Machine Corrosion-Resistant 316 Stainless Steel machines faster with less wear on cutting tools than standard 316 stainless steel.

Helical drill mill

Nickel alloys are exciting and revolutionary. The high strength, corrosion resistance and temperature uses are unparalleled. Please contact our sales team and we can assist with a quotation.

Jan 29, 2013 — Does anyone know where I might find an ACME thread form to use inside of SolidWorks 2012? I need both external and internal 1"-5 ACME for a ...

Industries such as energy, chemical, petrochemical, and power rely on nickel superalloys—those that present superior oxidation resistance and high-temperature strength—in critical applications. Alloys of nickel, chromium, and molybdenum provide enhanced corrosion resistance.

Drill Mill Cutter

Superalloys are made by adding balanced amounts of elements, including chromium, aluminum, cobalt, and titanium, to create optimal directionally solidified or single crystal structures, giving the material a strength that exceeds regular steel. These nickel-based alloys are utilized in extremely hot environments such as in gas turbines for power generation and in aircraft.

Many nickel-based alloys offer superior performances at temperatures above 1000°C, making them well-suited for extremely harsh environments. These offer excellent oxidation resistance at high temperatures while maintaining quality weldability, workability, and ductility.

A drill mill is an end mill bit that can be used for milling, drilling, chamfering, and v-grooving. These milling drill bits have a 60, 90, or 120 degree points on the end of the tool and two or four cutting edges. An end mill drill bit is designed drill through a part and then be able to side mill a groove or shape. They are very popular in job shop environments because of their versatility in performing a wide range of applications. Drill mill bits are solid carbide, and are available as uncoated or AlTiN coated.

Choose from our selection of milling machine arbors, including over 175 products in a wide range of styles and sizes. In stock and ready to ship.

Buy 37 Pieces Hand Drill Tool Set, Pin Vise Hand Drill, Miniature Drill Mini Twist Drill Bit, Bench Vice for Craft Carving Resin DIY Jewelry Making(0.3-1.2 ...

Drill Mill Bit

Decimal Equivalents from # 80 to 1", .0135" to 1.000" ; 31 .1200", 5/32 .1562" ; 1/8 .1250", 22 .1570" ; 30 .1285", 21 .1590" ...

Harvey Tool

Sep 11, 2017 — I use a 15 degree router bit and run the T molding on edge on the router table. Then rabbet the bottom of the T molding so that the edges that sit on the floor ...

Harvey Drill Mill

Different from a radial feed transformer, a loop feed transformer offers more redundancy, which can be essential in critical power supply systems where ...

Nickel alloy has a life span between 25 and 35 years on average and can last much longer depending on the application. With its extended service life, this material is more cost-effective than other metals. Nickel alloy is recyclable and is among the most recycled materials around the world. Approximately half of the nickel in stainless steel products comes from recycled nickel materials.

Shank Diameter (inch). 1/2 inch. Details. Individual/Set. Individual. Number of Flutes. 2. Number of Pieces. 1. Returnable. 90-Day. Router/planer type. Straight.

Carbide Drill Mill

Apprenticeship Classes. Machinists apprentices take 12 college-level classes. Each class consists of 50 hours of lecture and/or practical application. Upon ...

2023511 — Cutting Diameter: The cutting diameter of the end mill refers to the size of the cutting surface. Choosing the right diameter is important to ...

Nickel alloy is formed by combining nickel with other metals, commonly titanium, copper, aluminum, iron, and chromium. Approximately 3,000 nickel-based alloys are in use, forming products for numerous industries. Roughly 90% of all new nickel sold every year is used to create alloys. The most popular one is stainless steel, which accounts for approximately two-thirds of new nickel alloys produced.

Nickel alloy offers excellent advantages over other metals in numerous applications. Strength and resistance make it well-suited for everyday uses in critical harsh environments. For more information about Continental Steel’s nickel alloy products, request a quote today.

0086-813-8127573

0086-813-8127573