Solid Carbide Drill Bits for Stainless Steel - drill bit that goes through steel

Fsae michigan2024 schedule

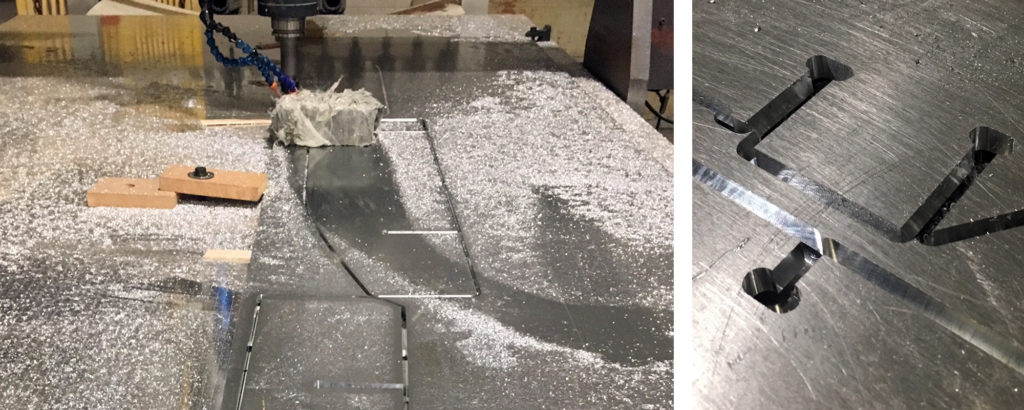

There are a few other strange things visible in the picture above – first, the paint stir sticks slid under the plate every foot or so. These let me cut through the work-piece without cutting into the aluminum machine table. They also help drop chips out of the slots as they are cut through. The other strange thing is the lead brick covered in plastic tape. The plastic tape is so you don’t touch the lead, and the lead is there to dampen vibrations in the plate. The operator has to move it around and keep it clear of the cutting head, but it keeps the sheet from chattering especially as large parts are cut almost free – except where they are held with tabs. Not pretty, but worked out well though!

Fsae michigan2025 registration

CBN Inserts - Grade CTB H15 - for machining hardened steels Extrême demands are placed on tools used for hard machining. The cost and service life of tools ...

This article contains information that reflects my opinions – I make no promises about its usefulness! It may contain mistakes (please let me know if you find some!) and will include prejudices based on my limited experience. If you disagree with anything here, please get in touch. This is not just for me to share what I know, but to learn from others. I will gladly insert additional information and differing opinions so readers are more aware of the diversity of “right” answers!

If you have a heavy duty machine and it is set up to handle it, flood coolant is excellent. It is the standard for milling metals in general and some routers can handle the flow of excess coolant off the table and back to the coolant pump. For light to medium aluminum work, you probably don’t need it. On a router it is unlikely to be the make or break issue because machines aren’t typically powerful or stiff enough to take heavy cuts.

We observe “National Engineers Week” with a banquet and technical program featuring presentations by students from Central Michigan University, Kettering University, Saginaw Valley State University, and The Kettering University AutoDrive Challenge Team. The students are members of SAE Collegiate Chapter project teams which compete in the SAE Collegiate Design Series http://students.sae.org/cds/ The design series has grown from a national competition to an international competition featuring students from Asia, Europe, North and South America. During this year’s banquet, the teams present will compete for the annual “SAE Collegiate Cup” presented by the Mid-Michigan Section. This event’s competition will be judged based upon the quality of the oral presentation of the team’s “Design Series” project.

When you make the jump from cutting wood (density up to 50lbs/cubic ft.) to aluminum (about 170lbs/cubic ft) you are cutting something four times as dense. As you’d expect the cutting loads go way up if you take the same cutter at the same speed – so don’t do that!

Dan Nicholson will discuss his various leadership roles at SAE, as well as how General Motors is positioned to lead in electrification with their commitment to Zero Crashes, Zero Emissions, and Zero Congestion.

Single flute tools are a huge help when cutting aluminum on a router. Typically you have plenty of spindle RPM but not much stiffness, and chip clearing is an issue. Single flute cutters are a “best fit” for this scenario. Look at this – the two flute gummed up and the single flute worked like a champ!

To make some useful calculations, we’ll start with a standard of 1000 SFM for our aluminum and D – the diameter of our tool. Lets imagine we have a nice 1/4” two-flute carbide up-spiral cutter. So D is going to be .25” and T will be 2.

The Formula SAE competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate, develop and compete with small, formula style vehicles. The competition is an engineering education competition that requires performance demonstration of vehicles in a series of events, both off track and on track against the clock. Each competition gives teams the chance to demonstrate their creativity and engineering skills in comparison to teams from other universities around the world.

The axial depth of cut (how deep your cutter flutes are engaged) is important too. If you have a low-power spindle with plenty of RPM, you may find it is better to move faster but take a shallow depth cut with an “Adaptive” style cutting strategy. Chip clearing will be easier and you may get better process reliability at the cost of only a little speed.

In 1981, SAE International (formerly known as Society of Automotive Engineers) developed and managed the first Formula SAE® (FSAE®) student competition with assistance of Ron Matthews, Professor at University of Texas. SAE International operated the only Formula SAE competition for 17 years before its partnership with IMeche (Institution of Mechanical Engineers) in England where the brand “Formula Student” was developed. Since its inception, Formula SAE has expanded and includes many spin-off events. In the North America there are three competitions managed by SAE International one in Michigan, California and Ontario, Canada. Internationally, the expansion of Formula SAE/Formula Student brand has exploded to over 20 competitions currently hosted by engineering societies or private business.

Your least messy option is compressed air – blowing chips out of the cut and keeping tool clear. Air itself doesn’t absorb much heat so this will only work for light cutting with no deep pockets… ideally with a single flute cutter or with a machining strategy that doesn’t involve single pass slotting. There are “cold air guns,” made by Vortec and others that work well, but any throttleable focused air blast should work ok.

Fsae Michigan2025

Perfect for enlarging or deburring holes in wood and plastic. Capacity: 1/8"-1/2"

Fsae michiganwinners

Thursday, Oct. 3, 2024 6:00 PM Social Hour6:45 PM Dinner8:00 PM ProgramMeal: Family Style Chicken & Liver dinnerTickets: $35.00 at the doorZehnders of Frankenmuth – Town Hall downstairs, 730 S Main St, Frankenmuth, MI 48734

Standard sizes for ball end mills range from very small diameters, such as 1/8 inch, to larger diameters, such as 1 inch, ensuring versatility for different ...

Once you are operating with reasonable “feeds and speeds” you are going to come to the next problem – how do you get chips out of the cut, and how do you keep the cutter cool? In an ideal world, the chips would be neatly sliced off and thrown well clear of the cut, taking all the heat that the cutting process generated away with them. This isn’t likely to happen… but you have options!

There are formulas to calculate the right range of cutting parameters for a given tool in a given material and machinists put a lot of effort into calculating “feeds and speeds.” Most tool suppliers will have specific guidelines which are very helpful. Here are some good resources to help with this:

If you see any mistakes or disagree with anything here I would love to have a chance to learn from you – please let me know!

Stepping up from air alone, you can use a coolant mist, or “minimum quantity lubrication” system. Fogbuster, Koolmist, and many others are common add-ons to CNC routers. You just need a reservoir and a nozzle and a compressed air line to the spindle area. There is enough coolant to provide some lubricity and to evaporate pulling away heat. It is combined with air to clear chips. It’s messy, but you can usually rig up some type of drainage system to keep liquid off the important motion and electrical bits. Minimum quantity lubricant systems are lighter on the air and more about providing a lubricant to the cut and less about clearing chips. Depending on the application, this may be plenty.

Cutter choice makes a big difference, especially if you are limited in your use of coolant. Many standard cutters are optimized for use with coolant in an enclosed machining center. If you’re using no coolant or just air-blast, you’ll need to be careful not to load up your cutters with rubbed or gummy metal. Avoid anything with more than two flutes. If you’re finishing a three-flute ball-end can be ok, but it is more prone to loading. The additional flutes increase the stiffness of the cutter though which can be helpful.

Teams are to assume that they work for an engineering firm that is designing, fabricating, testing and demonstrating a prototype vehicle. The vehicle should have high performance and be sufficiently durable to successfully complete all the event at the Formula SAE competitions. Each student team design will be judged and evaluated again other competing designs in a series of Static and Dynamic events to determine the vehicle that best meets the design goals and profitably built and marketed.

Nicholson began his General Motors career as a co-op student at Buick Motor Division. He has an extensive background in product engineering at GM and has progressed through a series of leadership positions including director of controller integration, director of engine calibration, chief engineer for V8 engines, managing director of GM Powertrain-Germany GmbH, executive director for global powertrain embedded controls, vice president of Global Quality and vice president of Global Powertrain.

This is a good start – and will probably work ok. Checking with manufacturer’s published data on SFM and Chip-load will allow you to use more tool-specific numbers and get better results. The 0.002” chip load we use in this example is on the low side for roughing with a 1/4” tool, and you may be able to crank it up quite a bit in the feed rate department without problems.

The way I prefer (if possible) is to actually clamp the material down with some kind of strap clamp arraignment. This works better for thicker material. Below is a picture of me cutting some 3/8” plate on a machine with a thick aluminum plate for a table. This table has tapped holes every few inches so strap clamps can be used. Best. Table. Ever! You can see some standard metal clamps like you’d see in a machine shop as well as a home-made MDF one which has longer reach and dampens vibration. I’m using a 1/4” single flute end mill with cold air blast.

Compete in static and dynamic events such as design, presentation, cost, acceleration, skidpad, autocross, endurance, and efficiency with vehicles powered only by electric motors.

Revolutions per Minute (RPM): This is just how fast the tool is spinning. The second hand on a clock goes 1 RPM. Hopefully your tool will be faster. Routers typically have plenty of RPM range, but not much low-end torque, so you’ll probably do best in the 8,000-25,000 RPM range.

PLEASE NOTE: OUR DOWNTOWN STUDIO HAS MOVED TO 380 BATHURST ST. We offer Forward Helix piercings to clients 14 years and up, provided a parent or legal ...

Teams are to assume that they work for an engineering firm that is designing, fabricating, testing and demonstrating a prototype vehicle. The vehicle should have high performance and be sufficiently durable to successfully complete all the event at the Formula SAE competitions. Each student team design will be judged and evaluated again other competing designs in a series of Static and Dynamic events to determine the vehicle that best meets the design goals and profitably built and marketed.

Website: http://www.korver.ca. External link for EM Precise Tools Ltd. Industry: Machinery Manufacturing. Company size: 2-10 employees.

In 2006, Dartmouth College (partnered with SAE International) created the fuel alternative event Formula Hybrid using Formula SAE cars with gasoline-electric hybrid power plants.

Fsae michiganResults

FSAE Michigan2024 Results

Dan Nicholson was appointed General Motors Vice President, Strategic Technology Initiatives effective October 2022. Until this recent appointment, Dan was VP of Global Electrification, Controls, Software and Electronics where he led the organization since January 2019 being responsible for all electrified propulsion products including batteries and electric drive units, as well as electronic control systems and strategies, software and associated electronic hardware for all General Motors products globally. Prior to that, Dan was General Motors Vice President, Global Propulsion Systems. In that role he was responsible for all propulsion products including engines, transmissions, fuel cells, electric drive units and batteries.

Chip-load Per Tooth (CPT): This is how much of a bite each tooth takes at the full programmed feed rate. Generally expressed in thousandths of an inch, for example our 1/4” carbide cutter might work well with 0.002” CPT.

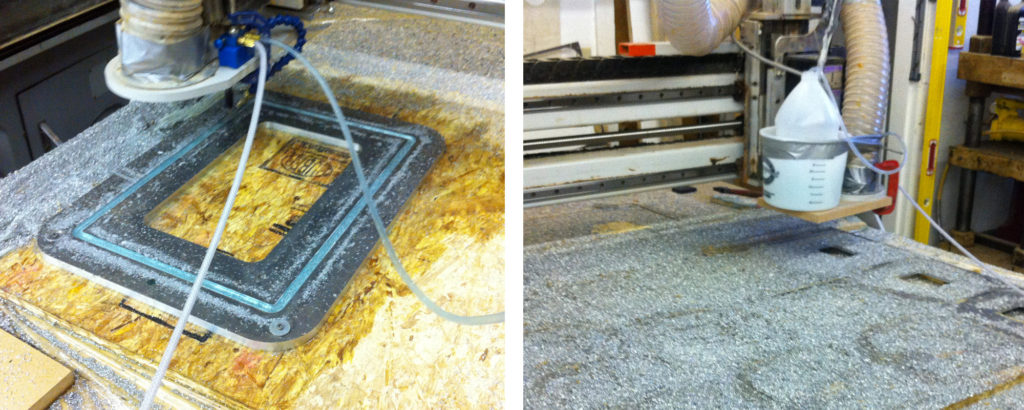

If your machine has a vacuum table, that is a good option if you have enough vacuum capacity to hold the sheet down as you cut more and more holes through it. Vacuum is great for production cutting, where you can set up a gasketed fixture that only holds the part where it will not be cut through. Given that aluminum is expensive and it is very hard to re-index a sheet that has shifted, it may be good to use a “belt and suspenders” approach and also mechanically fasten or index large (especially thin) sheets against fixed stops in addition to using vacuum.

You’ll also want to limit the “stick-out” of your tools to the minimum. Figure out how deep you need to cut and then add a little margin – maybe 0.125″ / 3mm – just so you don’t crash it. Short “stub-length” tools are great!

Aluminum is most often alloyed with other metals to enhance specific properties. An overview can be found here: Aluminum Alloys 101. Generally, the best machining alloys are the 6xxx series. This is good because they are very common and easy to get. Most extrusion is 6xxx alloy. The “xxx” means that there are lots of sub types of 6-series aluminum. 6061 is very common and is a good option for machining. I have machined 5xxx series sheet – once when a customer brought it to me – and it was a disaster on a router. Very gummy and prone to loading up cutters. Lesson learned. If at all possible, stick to 6xxx series alloys.

Fsae michigan2024 rules

Also you should be “climb cutting” by default – an option in your CAM software. This will take the fat part of the chip first and avoid rubbing and generating heat. Check out this quick article by Harvey Tool about the difference between climb and conventional milling.

For finishing operations, especially 3D ones with a ball-end mill – a “pre-finishing” approach will really help make the final surface nice. To do this you just make a set of operations that are the same as your finishing paths, but that leave a small bit of material (.02″ / 0.5mm) and use a larger step-over by 2 to 4X. These paths will leave a very uniform layer of material for the final finishing operations to remove. In corners, this will reduce the volume of material that needs to be removed and will eliminate steps from a roughing pass that can put uneven load on your cutter. Trying to muscle through a stepped rough finish with a finishing cutter can cause the bit (or machine) to deflect telegraphing the roughing steps into the finished part.

This site contains information that reflects the opinions of individual authors – mostly me, Chris. I make no promises about its usefulness! Some of this stuff can be dangerous and the warning “don’t try this at home” applies. You are responsible for your own judgement and outcomes. Be safe!

Feb 5, 2019 — All the techniques take advantage of radial and axial chip thinning. Cutting tool manufacturers have been designing milling tools to exploit chip thinning.

You can test how (un)stiff your machine is by getting a dial indicator and placing it to read deflection in some axis somewhere near the head. Grab the machine (spindle off) and pull on it as hard as you dare. Unless you have a really rugged machine it will move a lot. I had machine that cut wood very nicely and accurately but would deflect .06” (1.5mm) with just the pressure I could make with my hands. The truth is – if you’re doing it right – a cutter doing a normal machining operation creates a lot less load on the machine than you’d think! Match this with the software in machine controls that is designed to control accelerations gracefully – and a pretty floppy machine can make very accurate cuts.

Ray Theriault became Plant Director of General Motors Bowling Green Assembly in June 2023. Having grown up in Milford, Mich., Ray had the opportunity to listen as Corvettes would race around the Proving Grounds and always desired to be a part of the long and successful history of such an impactful vehicle. He grew up to receive a BS in Electrical Engineering from Lawrence Technological University and a Masters in Automotive Engineering from the University of Michigan.

ROLLING CRUISE begins with a ribbon cutting ceremony at 4pm at Factory One located at 303 W. Water Street in Flint. We will have our Grand Marshal Victor George and family, Mayor of Flint Sheldon Neeley, Local Police officers from surrounding precincts, our Chairman of the Board Al Jones, Vice Chairman of the Board Ralph Messer and other Board of Directors, Executive Director Amber Taylor and many, many others.

Nicholson earned a Bachelor of Science degree in mechanical engineering from General Motors Institute (now Kettering University), a Master of Science in mechanical engineering from Texas A&M University and a Master of Business Administration from Stanford University.

In 2013, Formula SAE saw the implementation of battery electric class to the portfolio already containing internal combustion gasoline.

If I had to choose something to machine, it would be “6061-T6” for general purpose stuff or “Mic-6” cast plate for things that have to be stable or benefit from flat initial stock. Mic-6 is an Alcoa product designation but the name is often used kind of like “Kleenex” or “Xerox” to mean just “cast plate”. It is cast in a sheet instead of extruded so it has minimal internal stress and won’t warp when machined. It also comes ground super flat – but it’s more expensive!

For more about machining aluminum with light-duty machines, check out this excellent video from NYCCNC: Shapeoko Feeds & Speeds and Machining Tips!

The Picatinny rail (/ˈpɪkətɪni/ or /ˌpɪkəˈtɪni/), also known as a MIL-STD-1913 rail, STANAG 2324 rail, or tactical rail, is a bracket on some firearms that ...

Surface Feet per Minute (SFM): This is how far a point on the surface – say the tip of a flute of the tool travels in one minute. Imagine you roll the tool along a surface next to a ruler. SFM is how far the tool would roll in a minute. This is not something we calculate – it’s more of a metric to say “how fast” we are cutting. Good guidelines can be taken from a table provided by a tooling manufacturer – or from rough guidelines for a material. For carbide tooling in aluminum this is about 600-1500 – higher for finishing, lower for roughing. For stainless steels and other heavy duty stuff, ideal SFM can be below 100.

In 2006, Dartmouth College (partnered with SAE International) created the fuel alternative event Formula Hybrid using Formula SAE cars with gasoline-electric hybrid power plants.

Above you can see the simplest option – drill some holes where you won’t be machining and screw it down to a sheet of plywood! Here I have also put some plastic sheeting down to protect the MDF bed of the machine. This is not a production-ready option, but if you have to get it done before lunch-time then this is worth a shot. You may have to use tabs (probably an option in your CAM software) to hold small pieces in place.

Don’t try to make things go better by going really slow! This is almost as bad as going too fast because instead of breaking your cutter right away – it will rub and generate heat and gum up – and then break. Resist the temptation to slow it down too much. You want to make sure the chips coming off the cut are actual chips. Grab a caliper and measure one – ideally the thickness at the “fat end” should be close the chip load per tooth value you chose.

Heat treating (for those alloys where it works) also effects the hardness of the material. Heat treat is shown as a number following the letter “T” – like “6061-T6.” Generally heat treated alloys will be better (harder and less gummy) for machining. The non-heat treated material will be designated “T3” or “T4” and the heat treated (or aged) will be “T5” or “T6” – so all else being equal, if you want to machine it, make sure you get heat treated material. Heat treated material is also a bit stronger. Anyone who sells metal will be much more aware of the details than I am – so ask before you buy.

Sep 6, 2020 — If you have made an error or had to cut the thread due to knots, you can fit two threads through the eye of most needles and stitch on. I ...

Cutter Number of Teeth (T): How many flutes/teeth does the cutting tool have? For aluminum, the fewer the better. Two is almost always plenty, and for sheet cutting or roughing without flood coolant, single flute cutters are awesome! (see below for more)

Formula SAE promotes careers and excellence in engineering as it encompasses all aspects of the automotive industry including research, design, manufacturing, testing, developing, marketing, management and finances.

Since joining the Bowling Green Assembly team, Ray has shown a true passion for the customer and has been driven to share customer enthusiasm with plant employees. He has fully embraced the unique external aspects of being Plant Director for Corvette by regularly engaging with the Corvette community through various events. He has also spearheaded a number of philanthropic efforts to support the Bowling Green community and its nonprofits.

You can also use vises like on a machining center. I have (very rarely) bolted a pair of vises to the table in a row and used them to hold extrusion for machining. Other people do this all the time and it worked great for me too – but my experience is limited! The machinists of the internet have got this covered.

How are you going to hold it down? Depending on your machine and your choice of coolant and chip clearing options, you have a bunch of ways you could do it…

Now you know what I know. It’s not comprehensive but its a start, and I hope it saves you a broken cutter or some other headache!

I’m going to preface this article by saying that I am not an expert at this! Many an expensive cutting tool has met its end while I “used” it to machine aluminum. There is a ton of good information from the world of machinists on the internet about cutting aluminum. Almost all of it is done with real metal mills and machining centers. Even a pretty dinky metal mill is much stiffer and less prone to vibration than a heavy duty router. This is a discussion around how to get decent results and not mess stuff up while using a tool that is ok but not ideal for a job.

The Formula SAE competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate, develop and compete with small, formula style vehicles. The competition is an engineering education competition that requires performance demonstration of vehicles in a series of events, both off track and on track against the clock. Each competition gives teams the chance to demonstrate their creativity and engineering skills in comparison to teams from other universities around the world.

In 2013, Formula SAE saw the implementation of battery electric class to the portfolio already containing internal combustion gasoline.

During the ribbon-cutting ceremony, MMSAE will award the H.H. Curtice award. Following the award the parade route will stretch from the historic “red bricks” of Saginaw Street in Downtown Flint through Burton and Grand Blanc

Township to the City of Grand Blanc. Thousands will line the streets to see classic cars and vehicles of every description.

FSAE michigan2024

Here’s a quick overview of what you need to know to choose a reasonable feed rate and RPM for your situation (Sorry, no metric yet!) :

Ray Theriault, Plant Director General Motors Bowling Green Assembly and Performance Build Center will provide an overview of the process for launching a new Corvette. From customer feedback to virtual reviews to early builds and beyond, the presentation will provide details on the various stages of build, until the start of regular production. Ray will conclude with a brief overview of the Corvette lineup.

Holding your material securely is very important. Because of the strength of the aluminum and the increased cutting forces, small parts and offcuts can get chucked with great force and speed – which is super scary. It isn’t unreasonable to rig up a shield or a curtain to protect yourself!

Formula SAE promotes careers and excellence in engineering as it encompasses all aspects of the automotive industry including research, design, manufacturing, testing, developing, marketing, management and finances.

Dan Nicholson will share his insights from his highly successful career at GM. Students will have the opportunity to ask questions and learn from a strong industry leader.

Jul 16, 2020 — I've had good luck with Kodiak burrs, Made In The U.S.A too. Carbide Burr Sets | Double Cut Carbide Burrs | Kodiak Cutting Tools. 1 ...

With a floppy machine you have to keep loads on the tool low and uniform or it will leave an ugly surface. Modern CAM packages have elegant toolpath strategies for maintaining consistent cutter load. For roughing, these strategies (called “Adaptive” for Autodesk products, “Dynamic” for Mastercam, etc.) are very effective and will give much better results. This is especially noticeable in corners or pockets where traditional strategies force the cutter to take a huge mouthful right as it changes directions!

First off a bit about safety – because cutting metal brings some real concerns that you don’t have while cutting wood or plastic! There’s a reason commercial metal machining centers have enclosures. Flying chips and coolant make a huge mess and also pose real danger to operators. The internet is full of videos of machines flicking parts out of vises and cutters braking off and going flying. With metal machining, the chunks are heavier, sharper and hotter. Wear safety glasses at all times while machining aluminum!

Ray has more than 28 years with General Motors, with a background in Global Propulsion Systems and Vehicle Assembly for both cars and trucks. He spent 5 years with GM International Operations in China where he was responsible for all GM manufacturing quality and quality assurance in Asia, Africa, and Australia. Ray has held titles including but not limited to Quality Manager, Quality Operations Director, Assistant Plant Manager and Assistant Plant Director during his tenure with the company. He was an integral part of the successful launch of heavy-duty pickup trucks in Flint, Mich., and the brands he has worked with have received various accolades including a number of JD Power awards and other prestigious quality and production honors.

For use with all Dremel high-speed rotary tools, the accessories work well for projects like metal or glass engraving, stone carving, or removing flash from ...

0086-813-8127573

0086-813-8127573